The EU-funded project IntelLiGent aims to develop innovative and sustainable high voltage Li-ion cells for next generation (EV) batteries. Battery electrode manufacturing is one of the key hurdles for upscaling of battery cell production, and is critical for enabling European industry to become self-sufficient in battery supply.

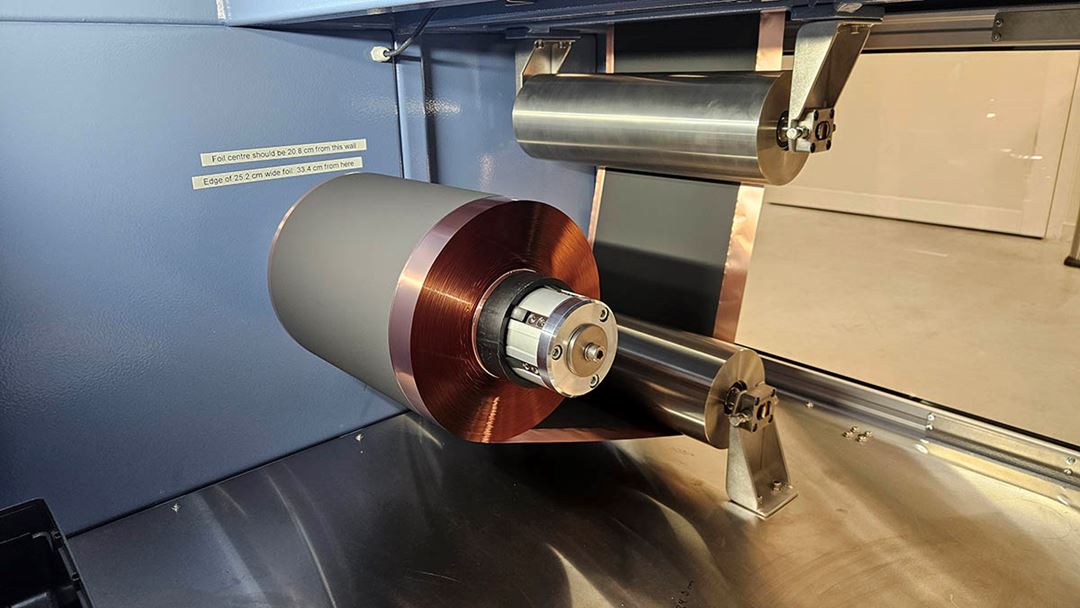

In batteries, the electrodes are thin layers which, in the IntelLiGent project, consist of lithium nickel manganese oxide (LNMO) cathodes and silicon-graphite anodes. In their recent work within the project, the Battery Technology group at SINTEF has now scaled up the production of these electrode layers to rolls exceeding 100 meters in length, with double-sided electrode coatings and with micrometer thickness accuracy.

Both electrodes were processed without the hazardous solvent NMP and instead made use of aqueous binders to prepare the high-loading electrodes in a more sustainable way. These electrode rolls will then be cut into smaller sheets and assembled into multilayered pouch cells for electrochemical testing.

– This is a great achievement for our group, done at the SINTEF Battery Lab, which is part of the NABLA infrastructure here in Norway. It demonstrates one of the first European examples of high loading water processed LNMO cathode upscaling, and also one of the first upscaled electrode production in Norway. Hopefully, this can be a much needed spark for Norwegian battery research to move towards industrial cell manufacturing locally, says project coordinator and Senior Research Scientist at SINTEF, Nils Peter Wagner.

The work has been completed together with the partners in the IntelLiGent project: Topsoe has supplied the LNMO material for the cathodes and Vianode has provided the Si-Gr anode material. The polymer group at SINTEF Industry has assisted with novel binder solutions for both electrode slurries, and AIT has assisted the upscaling of these different electrode chemistries. Millor will then prepare a battery module from the cells that are assembled from these electrodes. This will demonstrate the cell technology at a high TRL level, and be an important step towards demonstrating the potential of the LNMO||Si-Gr cell chemistry.

– The upscaling of battery electrodes is not trivial, and especially water-based processing at high loadings is proven to be very challenging. This is an important milestone for the project, as the quality of the electrode directly reflects on the quality of the battery cells that will be assembled in the coming months, says Nils Peter Wagner.