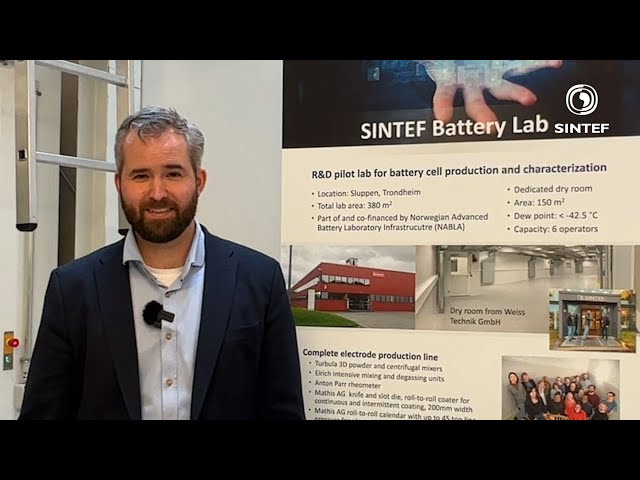

SINTEF Battery Lab a part of NABLA

Lab is realised with financing from SINTEF and The Research Council of Norway and is a part of NABLA – Norwegian Advanced Battery Laboratory Infrastructure (nablalab.no).

The primary goal for NABLA is to provide a national infrastructure dedicated to the battery research and development to Norwegian research and industrial organization.

NABLA covers research needs and interests of the battery field and is built upon expertise of six major Norwegian research institutions within battery research: IFE, NTNU, SINTEF, UiA, UiO and FFI.

SINTEF conducts research on all stages of battery cell production

SINTEF Battery Lab contains a 150 m2 dry room from Weiss Technik with a dew point down to -60 °C. This room contains a complete line electrode production line:

- Mixing battery materials (slurry)

- Turbula and centrifugal mixers

- Eirich high shear mixing and degassing units

- Evaluation of rheological properties

- Anton Parr rheometer

- Produce electrodes (coating, drying, compresses)

- Mathis AG knife and slot die, roll-to-roll coater for continuous and intermittent coating of electrodes with up to 200mm width (250 mm foil width). Infrared pre-dryer and two conventional drying chambers.

- Mathis AG roll-to-roll calendar with up to 45 ton line pressure and heated rolls for electrode compaction

- Assembling battery cells in a dry atmosphere

- Digatron assembly line for pouch cells consisting of electrode cutting unit, Z-stacker, ultrasonic tab welder, pouch forming unit, pouch sealing unit, electrolyte filling and degassing unit

Electrochemical formation and battery testing

We have equipment for electrochemical formation and battery testing in order to determine performance and cycle life, from the following manufacturers: Biologic, Metrohm Autolab, LANDT, NOVONIX, NEWARE

We are continuously expanding our equipment park for battery testing, and currently we have a total of 250 test channels for small and medium size battery cells as well as 120 channels for larger cells, including 16 channels for high precision testing.