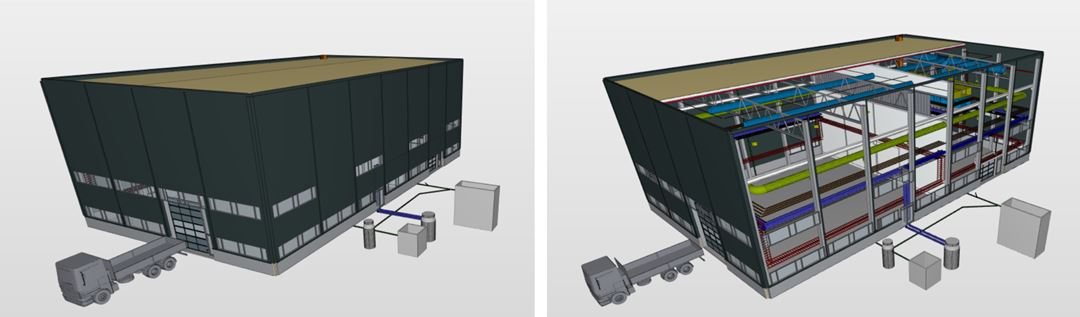

At Tiller, the industry already has unique access to relevant infrastructure and interdisciplinary expertise for developing and testing technology at larger scales under safe Health, Safety and Environment (HSE) conditions. The new building will be dedicated to piloting industrial processes, with the first pilot focusing on technology for utilizing captured CO₂ (CCU) through industrial biotechnology. This will further strengthen SINTEF’s ability to meet growing demands and opportunities in scaling and piloting sustainable and circular solutions.

– For over 40 years, SINTEF’s research community at Tiller has played a key role in piloting and scaling industrial processes. The new pilot facility will meet the industry’s need for testing and validating new green technologies, helping reduce greenhouse gas emissions and strengthen Norwegian industry, says Vice President Research, Duncan Akporiaye.

A growing need for research-based piloting

The new facility is being established in response to the need for a demonstration site for the EU-funded European Green Deal project PYROCO2, as well as the industry’s increasing demand for research-based piloting infrastructure.

Aligned with the EU’s strategic focus, there´s a growing interest for alternative, sustainable raw materials such as CO₂ and bio-based resources—for example, waste and forestry residues. Utilizing these materials requires the development of new green value chains based on innovative technologies and processes. SINTEF has had a long-standing focus on new bioprocesses, and advanced industrial biotechnology is already rooted in Norway. Collaboration between research and industry is central to this effort and has yielded important results, as seen in the SFI Industrial Biotechnology Centre and projects like PYROCO2.

Follow the construction progress live here:

Transforming CO₂ into valuable products

The PYROCO2 project aims to demonstrate the scalability and economic viability of using captured CO₂ (CCU) through an energy-efficient, high-temperature fermentation process that converts CO₂ and green hydrogen into acetone. This intermediate product can be further refined into sustainable products such as aviation fuel, plastics, solvents, and other valuable chemicals. The goal is to enable the use of up to 17 million tonnes of CO₂ equivalents by 2050.

– New methods for capturing, utilizing, and storing carbon (CCUS) from carbon-intensive industries can help reduce emissions, while making use of parts of the emitted carbon. Through biotechnological processes, captured carbon can be transformed into new products, and many industries are already exploring the opportunities biotechnology offers to move away from fossil-based processes—such as the industrial partners in the SFI Industrial Biotechnology centre, says Duncan Akporiaye.

PYROCO2 is the only technology platform of its kind in the world using gas fermentation to produce acetone from pure CO₂.

– Establishing the demonstration facility at Tiller enables more efficient validation of the technology at larger scales for the EU project, while also allowing SINTEF to showcase gas fermentation as a platform for new product classes, Akporiaye adds.

Herøya key to further commercialization

The facility was originally planned at Herøya Industrial Park in Porsgrunn, but after thorough evaluation, Tiller was chosen as a more suitable location for piloting, with Herøya remaining a key site for scaling up to commercial levels.

– When technologies are tested and developed for commercial use, strong research support is needed during the piloting phase. The location at Tiller provides close proximity to SINTEF and NTNU’s research environments, which offers significant advantages. It facilitates technology maturation before potential industrial deployment, says Akporiaye.

The new pilot facility is scheduled for completion in March 2026. Between 2026 and 2027, the Tiller facility is expected to produce up to 300 tonnes of acetone annually, from 700 tonnes of industrial CO₂ and renewable hydrogen. It will also provide essential research data for further scaling of the PYROCO2 technology—at Herøya and other industrial clusters across Europe.