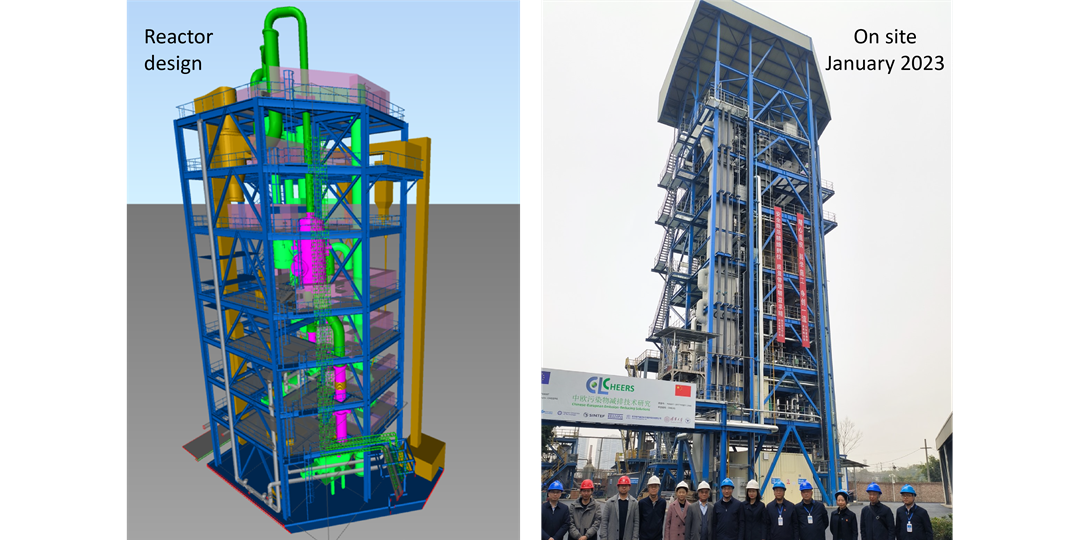

Waste-derived fuels like petroleum coke (pet coke) are an efficient source of energy – but they can also release incredibly polluting emissions when burned. The aim of the Chinese-European Emission-Reducing Solutions (CHEERS) project is to demonstrate how pet coke, lignite coal and wood-derived biomass can be safely burned to produce power or steam, while capturing CO2 and other harmful emissions, at a low cost. This is particularly important for utilising waste products for energy purposes or for achieving negative carbon emissions through bio energy with CCS (BECCS). As part of the project, a 3 MWth CLC demonstration unit was designed and constructed in Deyang City, China.

Using pure oxygen instead of air in combustion processes makes capturing and removing harmful particles from the resulting smoke much easier. This is because when pure oxygen is burned, the only end major products are CO2 and water, which are then easy to separate through steam condensation. However, producing pure oxygen is often expensive. Chemical looping combustion (CLC) technology avoids this cost, as extracting the oxygen already present in the air is an inherent part of the process.

CLC technology features a metal oxide that loops between an air reactor and a fuel reactor. In the air reactor, the metal oxide absorbs the oxygen from the air. It then goes into the fuel reactor, where this oxygen is used as an oxidiser for the combustion process. The oxygen-depleted (or “reduced”) metal then returns to the air reactor to absorb more oxygen, and the whole process repeats.

The demonstration unit in Deyang was commissioned in May 2023. It is 50 metres high and covers an area of 270 square metres. It has two different configurations for different fuels: pet coke and lignite. The goal is that the unit will be able to convert a solid fuel flow of up to 4 MWth into steam, while achieving a carbon capture rate of 96%.

If the testing is successful, it will demonstrate that the unit’s capabilities at TRL 7 (“System prototype demonstration in an operational environment”), making it suitable for deployment in industry, such as in refinery or power applications. Results are expected in the coming months.

CHEERS is an international project with nine partners from Europe and China: SINTEF Energy Research (coordinator) and SINTEF Industry, IFP Energies Nouvelles, Tsinghua University, TotalEnergies, Dongfang Boiler Group, Zhejiang University, Politeknika Slaska and Bellona. It is funded by the European Union’s Horizon 2020 research and innovation programme under grant agreement no. 764697, the Chinese Ministry of Science and Technology (MOST), and industry partners.