Fish farming is an important source of food, all across the world. But the industry is known for challenges related to safety, both in the form of frequent field accidents, and fish that escape the enclosure. Farmed fish on the loose and the resulting spread of unwanted gene material to vulnerable wild salmon flocks is a known problem. In addition, the aquaculture industry today has little access to customised systems that can operate autonomously, survey the enclosure and simultaneously collect important data from everything that happens inside.

From a purely technological perspective, the solutions exist. Automated underwater vehicles can tackle high-risk jobs such as the inspection of nets, which can lead to fewer accidents. What’s more, they can survey the fish’s health and prevent escapes. In fact, this type of equipment can even make the facilities more profitable since it can be “on guard” 24/7, regardless of terrible weather and without needing human assistance. This equipment can complete complex tasks such as examining the cage for possible damage in real time and thus preventing escape, and as a result, contributing to better animal welfare.

Tested in aquaculture facilities

A group of researchers from SINTEF and NTNU have now gone together with both the aquaculture and technology industries to develop a self-driving, also known as autonomous, underwater robot (ROV), officially called CageReporter. It’s tailor made for jobs like these, and it does it all on its own.

Project results:

- A low-cost underwater system for communication and positioning.

- A new system for 3D sight, which gives high-quality data collection and the possibility for data analysis.

- A new system for autonomous navigation/manoeuvring in non-static surroundings, with minimal need for interference.

- The ability to monitor conditions within the enclosure to improve fish's quality of life and health, as well as providing easier inspection of the net.

- A concept study which has resulted in recommendations and specifications for a complimentary docking station in aquaculture structures.

- The following publications:

Underwater Communication and Position Reference System - OC2020 A-034Data capture and real-time data quality analysis - OC2020 A-033

“Vehicles like this can collect useful data, making it more precise and more objective than the data we can collect as humans. Thus, the technology gives us incredibly precise and important information on, for example, the fish’s health and the quality of the water in real time. That’s great news for fish health and animal welfare,” says researcher and project leader Eleni Kelasidi from SINTEF. “In the future, we might even be looking at completely un-manned aquaculture facilities.”

The test-facility at SINTEF ACE, at the Norwegian coast. Photo: SINTEF

So far the ROV has been field tested at two aquaculture facilities connected to SINTEF ACE, just outside of Frøya on the coast of Trondheim. The facilities are operated by SalMar, but also function as a field laboratory for SINTEF researchers. It’s here that the robot has delivered both laser-sharp photos of the cage in real time, as well as precise positioning data which allows it to navigate in surroundings that are constantly changing. With this technology, CageReporter can discover and report any deformations in the net, and even anticipate future damage.

“The data we’ve received from the farming enclosure, both in regards to the fish, the equipment and the environment, have given us a much better insight into what the conditions in the enclosure actually are,” she says. “Compared to traditional point measurements, we’ve received without a doubt more information, and more importantly, more precise information.”

Armed with sensors and artificial intelligence

CageReporter is outfitted with some seriously robust technology. Its communications system is based on acoustic signals, yet is still small enough not to affect the ROV’s driving capabilities in the water.

This high-tech communications system was developed by the Norwegian start-up Water Linked, which has developed an ultrasound-based signalling system for underwater use that is both small, cost effective and high tech.

“We realized that there was a large market for this type of equipment, because the communication system that was available on the market seven years ago when we were first starting out, was large and required a lot of power while in use,” says Water Linked’s manager Oliver Skisland.

Realizing this demand in the market resulted in a seven-year long research stint, and today the company is experiencing great success with their solutions. Part of this success comes from their fundamental role in delivering the technology behind the SINTEF-led project CageReporter, with its miniature signalling system.

The core task at hand during the research project has been to make the vehicle autonomous, which has involved giving it both a brain, three-dimensional vision and various sensors that can survey the environment. Photo: SINTEF

“For us, it has been completely essential to have a precise system for positioning underwater. Without this, an ROV can’t navigate on its own. At SINTEF we have developed multiple advanced methods for real-time calculations of, for example, deformations in the enclosure’s net and interactive navigation for this type of vehicle. Now we have demonstrated that the robot truly can do the job,” says Kelasidi.

Researchers made it autonomous

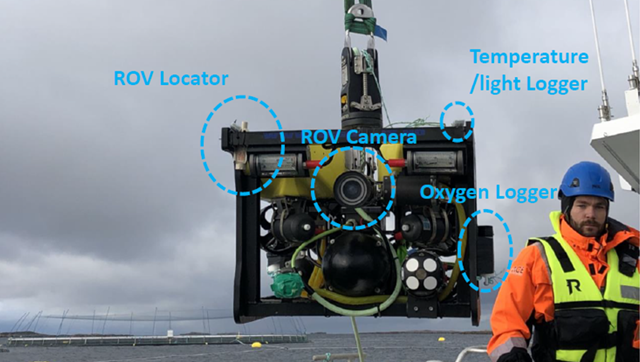

The core task at hand during the research project has been to make the vehicle autonomous, which has involved giving it both a brain, three-dimensional vision and various sensors that can survey the environment. The ROV needs to coexist together with living fish and changing environments, and needs therefore to be able to use its senses to navigate and regulate itself.

“This has been challenging,” says researcher Eleni Kelasidi. “Our team developed numerous algorithms that can estimate the distance to and movements of various objects, both the actual enclosure and the fish swimming in it. Those models were then combined with real-time measurements from positioning systems in order to estimate the surroundings and adjust movements in real time. A lot of emphasis was put on the development of a biointeractive control function so that the ROV can better coexist with the fish without disturbing them.”

Kelasidi explains that these algorithms were then programmed into the vehicle itself, which was made up of various sensors and a camera. The data they gathered was analysed via computer systems and artificial intelligence which resulted in a status report for the fish and their environment.

But getting these systems and algorithms to work together on their own and with extreme precision, as well as programming this into the robot’s movements without scaring the fish, is difficult.

“When the fish get scared, their flight instinct kicks in, and that means that we can’t get the observation we need. Thus, it has been important for us to ‘teach’ the robot to slow down when necessary, so that the fish accept it as part of their environment,” explains Kelasidi.

After the ROV has been accepted into the school of fish, it can travel wherever it needs to within the enclosure. In most aquaculture facilities today, sensors are found at only one location – by the feeding station. But conditions within the enclosure can vary widely from area to area in terms of temperature, currents, lighting and levels of oxygen. A self-driving sensor has the advantage of being able to monitor the entire enclosure, and this gives us a more complete and accurate picture of the conditions inside.

Kelasidi concludes that due to the sharp increase in the aquaculture industry that we see today, the automated inspection that CageReporter provides is completely necessary to optimise operations.

Facts:

Project Leader: SINTEF Ocean AS

Project participants : WaterLinked AS (Project Owner), Sealab AS, Norsk Havservice AS, NTNU, HES-SO and SINTEF

Financing: The project is co-financed by the Norwegian Research Council and industry partners

Duration: 01/01/2017 - 31/12/2019

Facilities: SINTEF ACE