“It’s satisfying to see that many people are seeing the potential of algae and plankton”, says Centre Manager and Research Director Gunvor Øie at SINTEF Ocean. “Our aim is to contribute towards establishing a new biomarine industry in Norway. Some people believe that algae and plankton will be the new oil”, she says.

Seaweed production adjacent to fish farms

Last year, the plankton centre received just over NOK 19 million from the Research Council of Norway to fund the construction of laboratories where researchers and the industry intend to develop concepts for future commercialisation. SINTEF is administering the centre together with NTNU, and the funding has made it possible to develop a new infrastructure in the laboratories, which contain microalgae (single-celled algae), macroalgae (seaweeds) and zooplankton (including copepods, amphipods and bristle worms). The centre aims to identify methods of production, harvesting and processing of these small organisms, and work at NTNU and SINTEF is well underway.

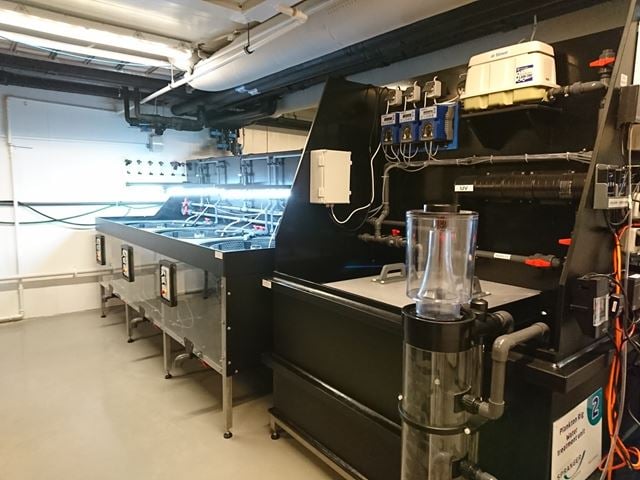

This experimental rig will be used to research into everything from zooplankton to fish larvae.

The flexibility built into the system provides the opportunity to create conditions identical to

Those used in the industry. Photo: SINTEF.

“We’ve been testing several systems for seaweed cultivation, in which the spores we cultivate will in time be transferred to the sea as part of a large production facility”, says Professor Kjell Inge Reitan at NTNU. “These seaweed farms can be located close to fish farm facilities, so that the seaweed can obtain nutrients from the waste materials produced by the salmon farms”, he says.

Sustainable feed for farmed fish

Norway aims to expand its aquaculture sector by five-fold in the years leading up to 2050. In order to achieve this, more feed must be manufactured for farmed fish. One of the approaches that may be used to achieve this is the production of microalgae containing high concentrations of fat, which is an important ingredient in fish feed. Currently, soya is imported from overseas, and some of this is produced on land previously covered by tropical rain forests. This is expensive and not very sustainable.

“Much of the fish feed is produced on land and contains too little of the beneficial fatty acids”, says Jorunn Skjermo, who is a Senior Research Scientist at SINTEF, and Project Manager for the project called COMPLETE. “With a larger proportion of algae in the feed, its nutrient value will be enhanced and the fish will be able to feed on natural and healthy food”, she says.

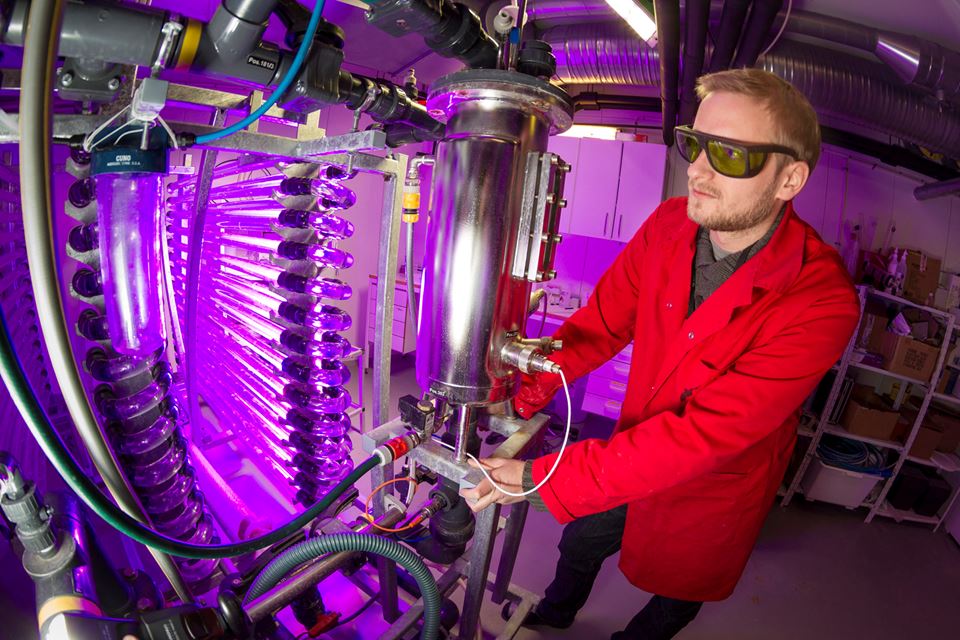

Optimal light conditions and full control of temperature and pH conditions allow the cultivation of microalgae to be carried out efficiently in these pipes.

Photo: SINTEF.

During this project, SINTEF is working together with a biogas facility in Skogn in Nord-Trondelag county, which is aiming to cultivate algae in the wastewater it produces. The researchers have already started test production of microalgae in laboratories located at the Plankton Centre, which is located on SINTEF Ocean’s

premises at Brattøra in Trondheim.

“The waste water we used for the initial experiments was strongly discoloured, and this caused problems for microalgae production”, says Matilde Skogen Chauton, a Senior Research Scientist at SINTEF Ocean. “We are now testing water produced by a different stage of the process at Skogn, which contains less of the discolouring substances. We hope that this will make production much easier”, she says.

Working with Statoil

Statoil has contracted the centre to carry out oxygen measurements on cod eggs and larvae, as well as the cultivation of feed organisms. The main aim of these experiments is to study and document the impacts on relevant marine species of chemicals (synthetic polymers) that may be used in connection with improved oil recovery.

“How important is it to have access to the Plankton Centre?

“From our point of view it is important that our suppliers of services and research projects have adequate access to marine plankton species that can be used in standard toxicity tests, as well as species that are relevant in the marine environment”, says Randi Hagemann at Statoil.

Bladderlocks seaweed is very beautiful close up. In the future seaweeds

may form the basis of a profitable industry in Norway, as is already the case in Asia.

Photo: SINTEF.

Commercialisation is a key part of the efforts being made at the Norwegian Centre for Plankton Technology, and one of the companies that has emerged from the SINTEF start-up community is called C-Feed. The company sells feed ingredients for species other than salmon to the marine aquaculture sector.

Selling live fish feed

“What makes salmon larvae special is that they can feed on pellets right from the start”, says CEO Tore M. Remman at C-Feed. “Most other fish species need live feed in order to survive”, he says.

Plankton production takes place on land, and the company sells fresh eggs and plankton.

“Live feed for a variety of fish species may become big business overseas”, says Remman. “In Norway we sell feed for cleaner fish, among others”, he says.

“How important is it for you to have access to the laboratories at Brattøra to support your future development?”

“We need more research into how to breed new species such as tuna”, says Remman. “We’ve already carried out experiments with our products and have obtained good results. But we still have some way to go, so the plankton centre will also be important to us in the future”, he says.