Over the last decade, the Flow Technology research group in SINTEF Industry has established world leading expertise in fluidized bed reactor technology, using a strategy that synergistically combines experiments and modelling. Although this experience was attained primarily from developing advanced reactor concepts for low cost CO2 capture, it can be readily applied to the optimization of existing fluidized bed processes or the development of novel processes in other fields.

Our expertise includes the following:

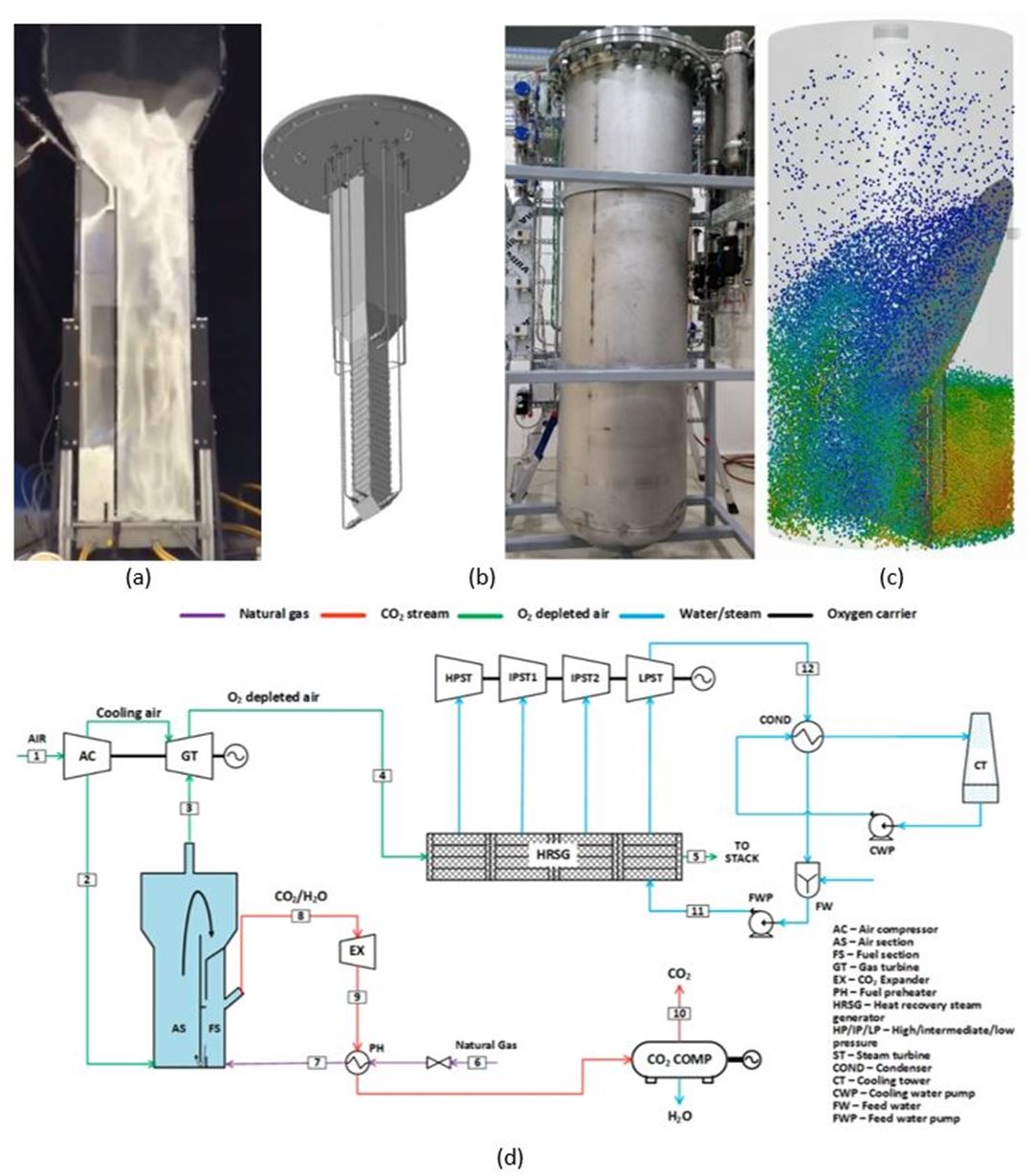

- Flow visualization:

- Particle image velocimetry (PIV) and digital image analysis (DIA) for visualizing flow behaviour in fluidized beds.

- This quantitative data is used for better understanding of reactor dynamics and for validating Computational Fluid Dynamics (CFD) models.

- Demonstration of novel reactor concepts:

- Lab-scale experimental reactors have been constructed and operated under high temperatures (up to 1100 °C), high pressures (up to 20 bar) and strong vacuums (down to 0.05 bar).

- CFD simulations complement these demonstrations by contributing to the design of the demonstration reactors and by aiding the interpretation of experimental results.

- Large-scale fluidized bed reactor simulations:

- Pilot- and industrial scale fluidized bed reactors are challenging to simulate accurately due to the enormous number of particles in such systems.

- We have developed multiscale modelling techniques to enable computationally affordable CFD simulations for the purpose of large-scale reactor design.

- In addition, pragmatic 1D and 0D reactor models have been developed for enabling process simulations involving novel fluidized bed reactor concepts.

- Techno-economic analysis:

- Quantification of the impact of a novel fluidized bed reactor concept on techno-economic performance is a vital part of the business case for further scale-up.

- We have extensive experience with combined reactor and process simulations and economic assessment for benchmarking novel fluidized bed processes against appropriate reference technologies.