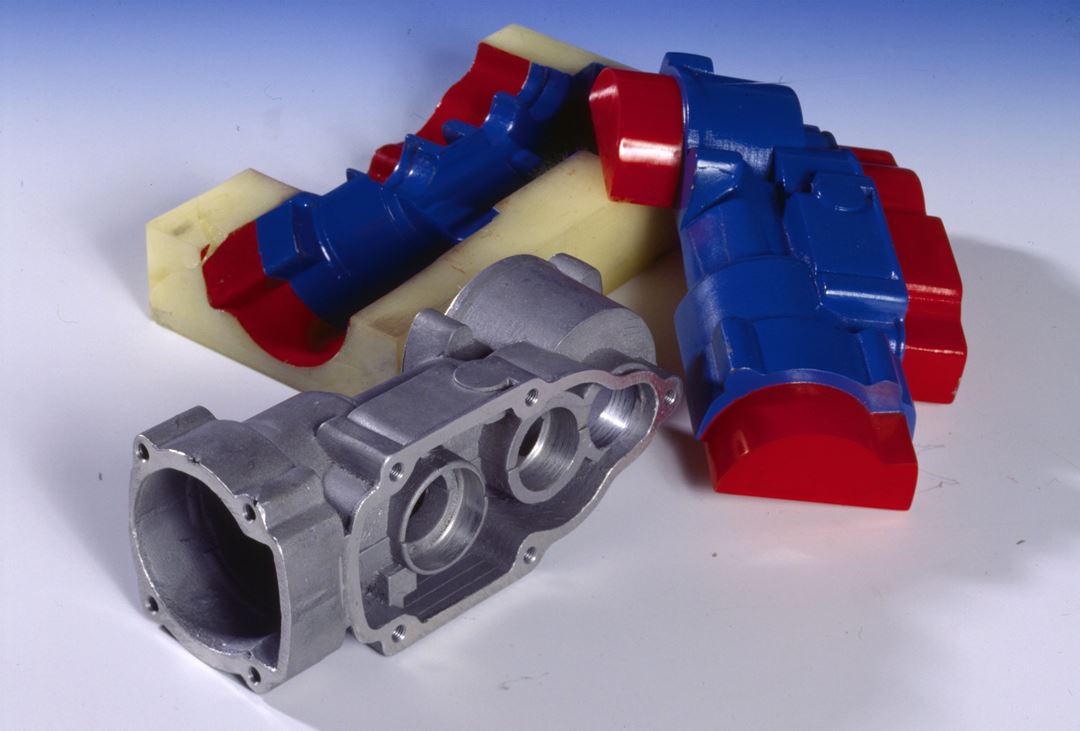

We design and produce models for shaped castings and have a moulding line and a core shooter to produce sand moulds. In addition, we have a casting jig for permanent mould casting. We lean on advanced modelling to optimize gating and feeding systems. We cast products from simple test bars to advanced prototypes and products.

We have access to a range of furnaces from open crucible furnaces to advanced vacuum furnaces. Melt capacities are ranging from about 10 ml to about 50 l depending on material and set-up. A modern data acquisition system enables us to collect data from all experiments for further analysis by our skilled researchers. Some of our laboratory equipment is commercially available, while other equipment are specially designed and made in-house for our purpose.

Examples of our equipment are:

- PoDFA – Porous Disc Filtration Analysis

- ALSPEK H – Equipment for measuring hydrogen in Al melts

- HYCAL - For real-time measurement of dissolved hydrogen in aluminium melts (Part of National Infrastructure TEMP)

- Metal fluidity measurement equipment

- RPT – Reduced pressure test equipment

- Feeding measurement equipment

- Low pressure die casting station

- Cast-forging equipment

- LIBS - For chemical analyses of aluminium melts (Part of National Infrastructure TEMP)

- Handheld XRF - For chemical analysis of solid samples (Part of National Infrastructure TEMP)