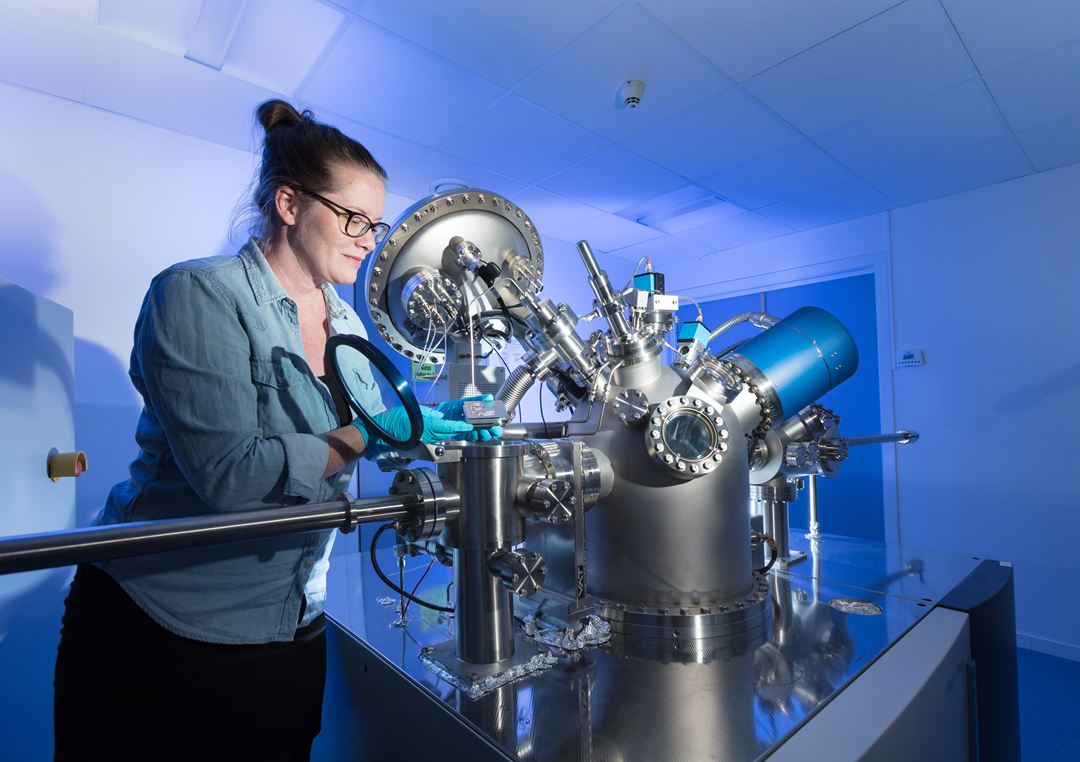

X-ray Photoelectron Spectroscopy (XPS)

SINTEF Materials and Chemistry, in partnership with the University of Oslo, operate a state-of-the-art spectrometer for X-ray Photoelectron Spectroscopy (XPS). In-situ and/or near in-situ sample treatment combined with advanced surface analysis are performed by scientific personnel having more than 15 years experience in the field.

Contact person

What information we obtain:

- Qualitative and quantitative elemental analysis of surfaces within a depth of 5-10 nm. Applicable to all elements apart from H.

- Chemical state identification of elements at surfaces and interfaces.

- Compositional and chemical state depth profile with Ar+ ion sputtering over several hundreds of nm or via angle resolved XPS (see figures) over the outermost few nanometres.

Sample requirements:

- Sample dimensions (maximum): height 25 mm, width and length 10 mm

- Vacuum compatibility, surface free of oil, grease, fingerprints etc

- Best sample packing: Al foil with the mat side in contact with sample surface

Typical areas of application:

- Understand/evaluate the corrosion/oxidation of metals.

- Characterise catalysts and study their degradation.

- Investigate nanomaterials and nanostructured surfaces .

- Analyse micro-/ nano-electronics, thin films.

- Study solar and fuel cell materials.

- Examine natural & industrial polymers, adhesives, paints, fillers etc.

- Evaluate the effect of surface treatments and modifications.

Industrial sector that XPS analysis can provide solutions:

All cases where analysis of surfaces and interfaces is important in trouble shouting, process/product quality control and R&D activities. Typical examples are metallurgy, construction, chemistry, energy (gas, oil, renewable), microelectronics, transportation.

Relevant links

Infrastructure networks:

Projects: