Modelling

Modelling offers many practical advantages, especially when starting at the early stages of development:

- It helps build a better understanding of the first principles, strengthening the entire project.

- The complexity of an application can be captured by exploring multiple simpler, isolated, models, gaining valuable fundamental knowledge. Integration into a complete model can follow, if needed.

- The modelling approach can be adapted to specific tasks and focus points, using the best tool for each job.

- Models can be designed to be highly reusable and adaptable, evolving with lab or field results, or during phases when project priorities change.

- Modelling is a highly cost- and time-efficient for exploring design options and uncovering potential show-stoppers.

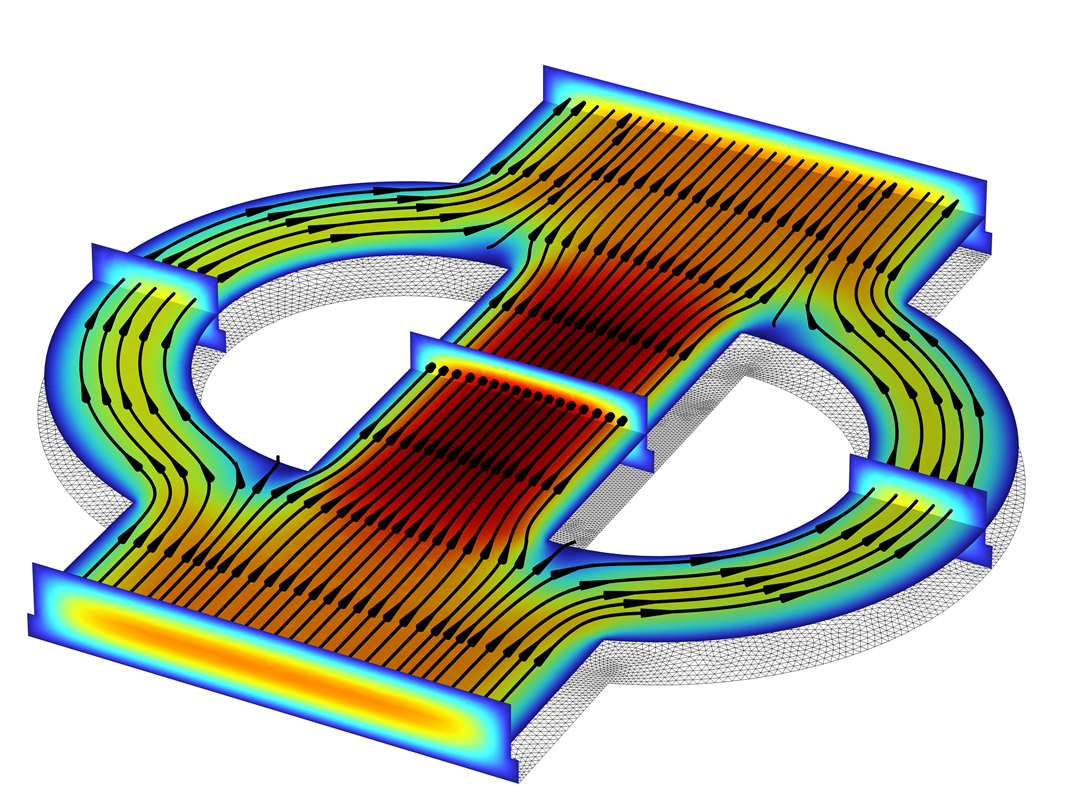

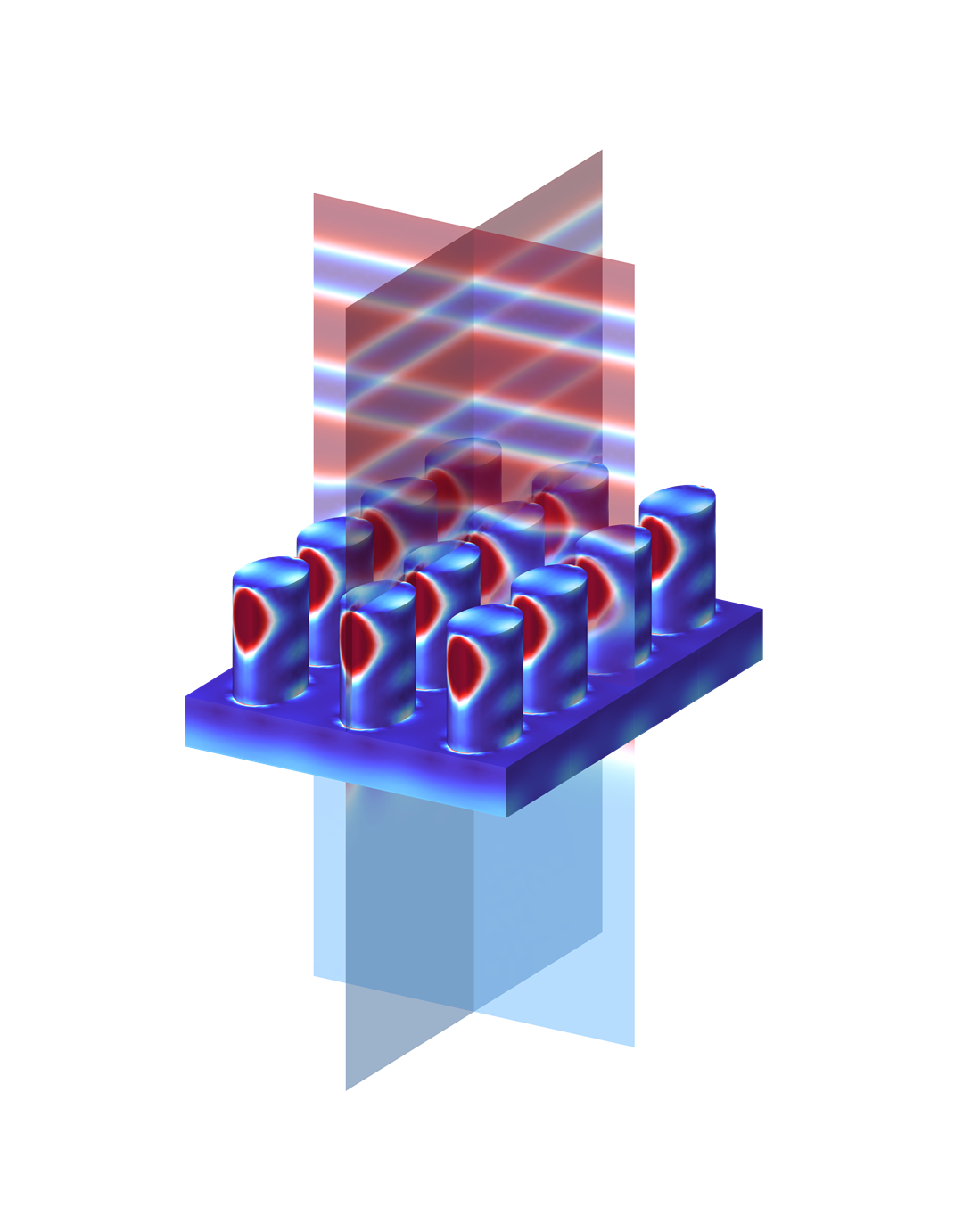

A variety of mathematical and simulation tools

For demanding sensing applications, we employ a variety of mathematical and simulation tools to create bespoke models of relevant physical phenomena. This gives us a solid foundation on which to develop better solutions. We can evaluate how different design choices affect performance, test the effect of operating conditions, and assess potential failure modes. This, combined with our classical prototyping approach, makes it easier and faster to achieve complex sensing goals—often at a lower cost.

Examples of areas which can take significant advantage from modelling are:

- Design and geometry optimisation, e.g. optics.

- Optimal choice of materials

- Evaluation on performance of external/operating conditions (e.g. temperature, pressure, etc.).

- Testing of failure modes (e.g. thermal, mechanical).

- Assessing sensor integration with larger systems (e.g. real-time data processing, AI model training).

To tackle complex problems, we can use a combination of different modelling approaches, using both commercial and in-house tools. These include:

- Ray tracing (Zemax, COMSOL Multiphysics).

- Finite Element Method (COMSOL Multiphysics).

- In-house model toolbox (Python, Matlab, Mathematica).

- Analytical mathematical methods.

We work closely with our partners, whether they prefer a hands-on approach or not. For example, we can:

- Run all simulations and deliver detailed or high-level results and recommendations.

- Deliver models that partners can run locally, enabling their R&D team to take charge of the modelling.

- Deliver user-friendly applications for technical and non-technical staff, for use in the lab or in the field.