The ammonia industry has over a century of experience in producing, storing, handling and transporting ammonia. Ammonia is considered a promising zero-emission fuel alternative, as it does not contain carbon and therefore does not produce carbon dioxide when it is burned. In addition, ammonia is easier to store and has twice the volumetric density compared to hydrogen, another potential zero-carbon fuel.

Ammonia is particularly interesting as a fuel for ships or vessels with limited fuel storage capacity. Other applications for ammonia include being used as an energy carrier for hydrogen, being part of the solution for decarbonising offshore industry, and being used as an environmentally friendly refrigerant.

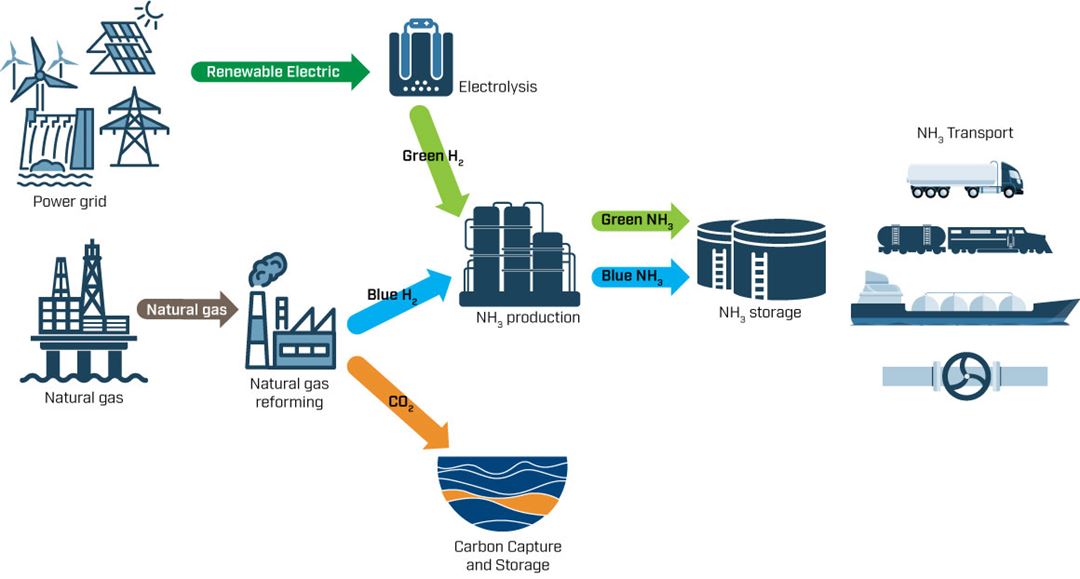

Ammonia is produced from hydrogen, which today is mostly produced from natural gas. For ammonia to truly be considered as being “zero emissions”, it must be produced using either renewable electricity (“green ammonia”) or natural gas in combination with carbon capture and storage (CCS) (“blue ammonia”).

SINTEF has research activities along the entire ammonia value chain, from production to use as a fuel onboard ship, in offshore installations, as well as refrigerant. We also research safety and environmental aspects related to the use of ammonia.