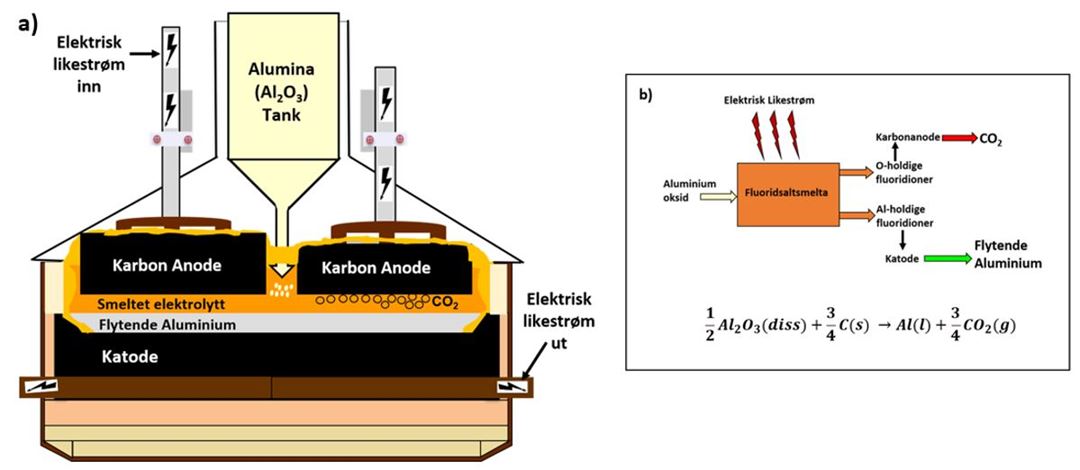

It is a very energy-intensive process that consumes approximately 12-15 kWh/kg Aluminium and emits approximately 1.5 kg CO2 per kg Aluminium produced.

There is therefore a great deal of focus on reducing energy consumption and achieving lower greenhouse gas emissions. Cell design, material selection, good process understanding and process control, and longer cell life are also important topics. Environmental emissions in the form of gases, by-products and residual materials are also a major focus.

We work in the following areas:

- Energy efficiency

- Salt melting chemistry

- Alumina addition and properties

- Gas bubbles

- Bath/metal flow

- Anode technology (carbon)

- Cathode technology (graphite)

- Cathode bars (Fe-Cu)

- Heat balance

- Cell design

- Heat recovery

- Material technology

- Testing of refractory bricks, concrete, cement and insulation materials

- Testing of side-lining materials including Si3N4 bonded SiC, graphite, etc.

- Anode characterization- fossil and biocarbon anode

- Cathode characterization- graphitized and semi-graphitized bottom coal, etc.

- Cathode steel shell corrosion

- Environmental technology

- Gas measurements- PAH, PFC, SO2, SO3, etc.

- Dust measurements

- Recovery of excess fluoride bath

- Utilization of materials from SPL carbon, cathode bars, refractories, etc.

- Utilization of dross and Al metal scrap from the process

- New processes

- Cells for CCS opportunities

- Biocarbon/bio binders for anodes

- Inert anodes

- Drained cathodes

- Chloride process

Typical assignments for us are:

- Projects supported by the Research Council (KSP, IPN, FME)

- Projects supported by the EU (Horizon EU, etc.)

- Direct projects with Al producers nationally and internationally.

- Direct projects with refractories and cathode producers

Who do we do this for:

- Norwegian Al industry (Hydro and Alcoa Norway)

- International Al companies (EGA, Alcoa US)

- Refractories producers worldwide

- Cathode producers worldwide

Relevant projects:

- KSP BiocarbUpgrade

- FME ZeMe

- IPN Badeland

- IPN ZEAL

- Horizon EU REVEAL