This summer, I am doing three months internship in Trondheim, Norway at the SINTEF department of Materials and Chemistry. My work is part of the ROP project (repair contingency of pipelines), which is a competence research project (KPN) within the Petromaks 2 Programme of the Research Council of Norway.

More precisely, I am performing fracture mechanics testing of compact tension (CT) specimens according to BS 7448-1 for the determination of critical CTOD and BS 7448-4 for determination of fracture resistance curves. I am working in close cooperation with Dr. Vigdis Olden, NTNU PhD candidate Lise Jemblie and researchers at SINTEF Materials and Chemistry.

The small CT specimens that I was given were machined and eroded from butt-welded structural steel pipes (X70) with an inner corrosion resistant alloy (CRA). The specimen location is the heat affected zone (HAZ) with the notch positioned at the interface between the CMn steel and clad (AISI 316).

To perform fracture mechanics testing, I am using a Cormet Slow Strain Rate test rig and the experiments are carried out in two types of environment (air and in electrochemical hydrogen charging conditions in situ) in order to assess the influence of hydrogen embrittlement on clad pipes.

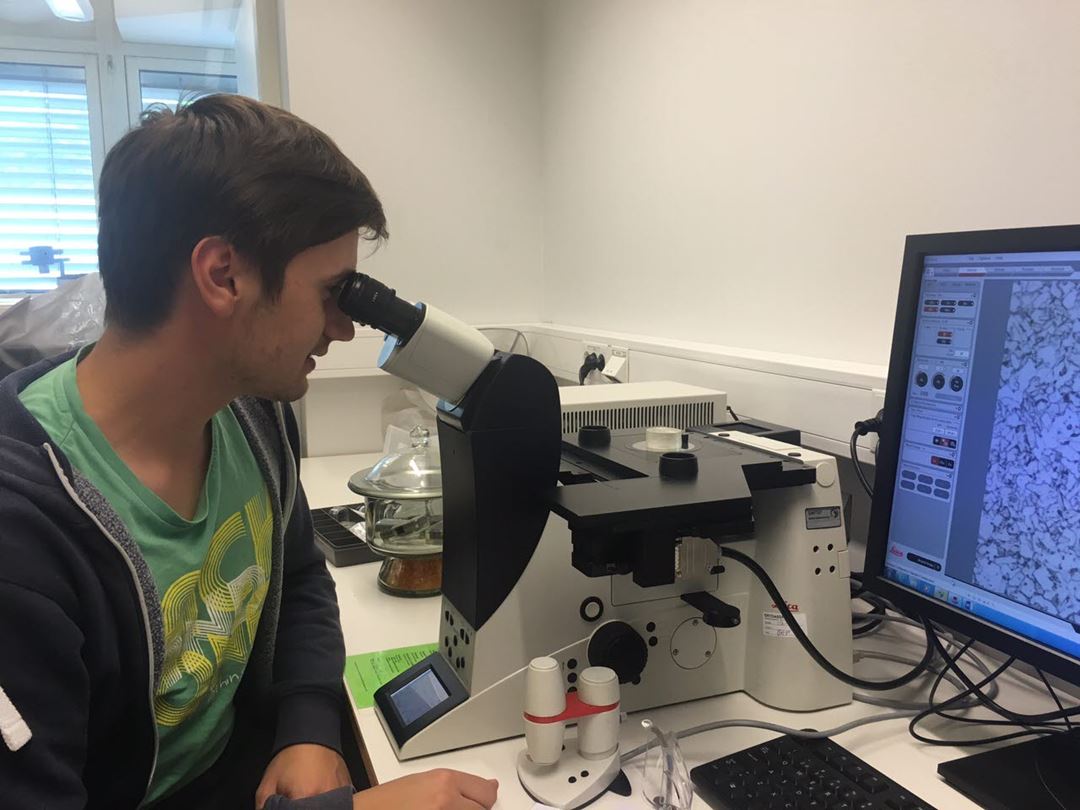

Then, the second main part of my work consists in characterizing the fracture surfaces of selected samples using SEM and establishing the fracture path by investigating the cross section using optical microscopy.

I wish I could translate it in Norwegian but I think it is beyond my skills!!