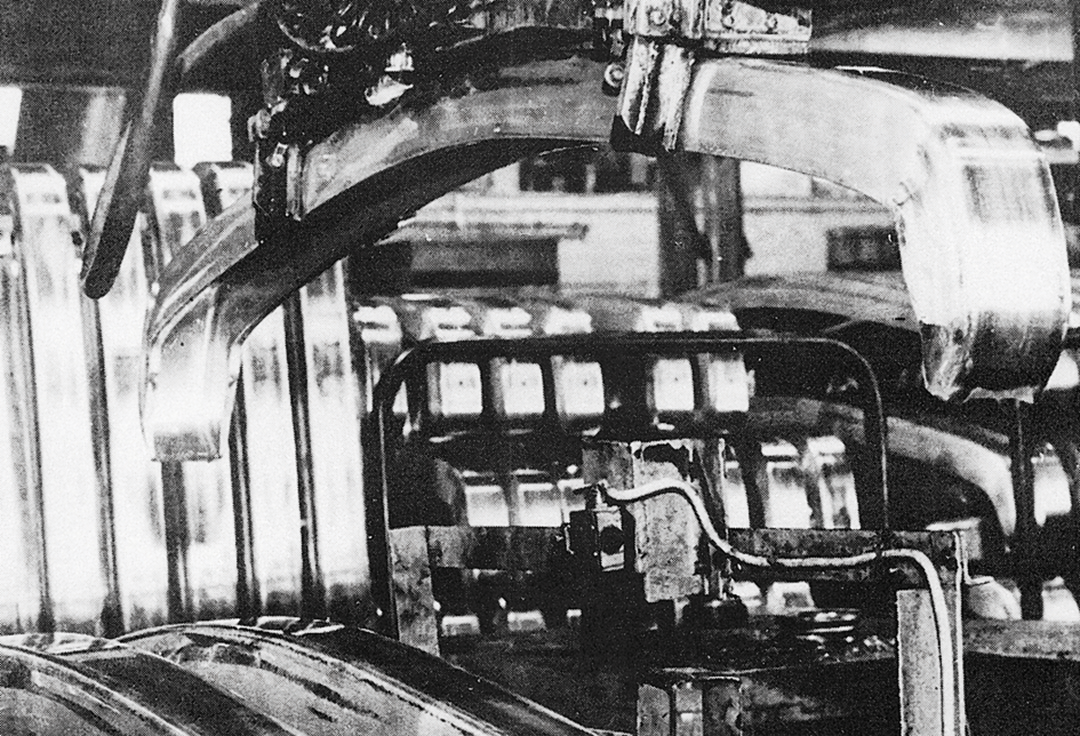

As early as 1966, Raufoss Ammunisjonsfabrikk (RA) had started mass production of bumpers for Volvo. For this purpose, the company used a relatively low-strength aluminium alloy, compared to what would emerge from Raufoss in the years to come.

In 1972, the American authorities decreed that bumpers should be able to withstand collisions at speeds of up to 13 kph, without damage to either the car body or the bumper itself. This led Volvo to ask RA to tender for what they called a safety bumper.

High-strength bumpers for Europe

As a result of several years of collaboration with SI, RA already had a suitable alloy available, not to mention the necessary design expertise.

This was the beginning of large-scale production of high-strength safety bumpers at RA – first for Volvo and then for several leading European vehicle manufacfturers.

A central role in RA’s development efforts was played by Bård Eftestøl, a research scientist at SI between 1962 and 1965. In 1988 he was awarded NTNF’s Prize for Research Excellence for his work.

Driving force for further research

Social science professor Jon Gulowsen wrote as follows in SINTEF’s anniversary volume in 2000: “The fact that the project acted as a driving force for light metals research in Norway may have been just as important as the purely technological advances it produced.”

Nils Ryum, since 2004 an emeritus professor at NTNU, worked on the SI project for five years as a young scientist. In 1970 he became a professor at the Norwegian Institute of Technology (now NTNU), where he established light metals as an area of special emphasis in teaching and reseach at SINTEF/NTNU.

Between 1972 and 2001, NTNU awarded more than 120 doctoral degrees in this field (including silicon, but in most cases light metals). Today, SINTEF/NTNU is regarded as one of the world’s leading centres of excellence in light metals research.

Bumpers still coming from Raufoss

Today, the bumper plant at Raufoss Industrial Estate is owned and operated by Benteler Aluminium Systems Norway AS, a division of Benteler Automotive. In 2011, the Raufoss plant and its 520 staff produced some five million bumpers.

Expanion elsewhere in the world

From its start in Raufoss, the company expanded in the 1990s, establishing factories in Michigan and in Louvier in France, as well as a unit in China in 2011.

According to Svein Terje Strandlie, head of the Raufoss factory, the bumpers produced by all these plants are the result of a continuous process of development that began with the “Volvo alloy” in the early 1970s.

1972: Making stronger car bumpers

In the early 70s, the authorities in the USA set out stricter requirements for what car bumpers should be capable of withstanding. A big factory in little Norway took up the challenge.