|

|

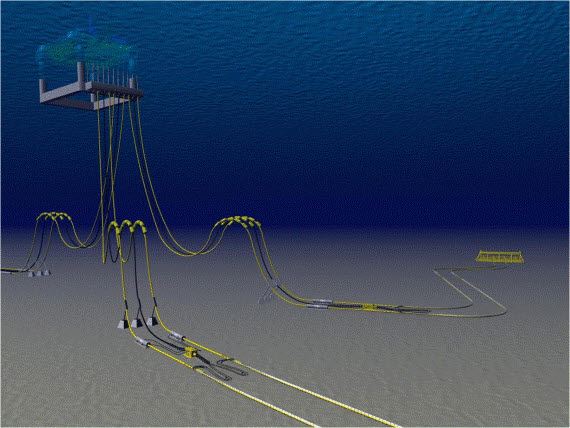

Pipelines with a system for direct electric heating (DEH). The power supply cables (black) run parallel to the risers (yellow) and are connected to the DEH cables on the seabed. Illustration: Nexans |

How can we prevent ice-cold plugs from forming in Norway’s arteries on the seabed? Ths question was the backdrop for a joint effort by Norwegian scientists and industry to develop a system for direct electric heating.

The system was designed and installed in order to prevent ice-like gas hydrates and waxes from blocking the pipelines that carry oil and gas from subsea fields ashore or to platforms on neighbouring fields.

The solution was the result of cooperation between Statoil, SINTEF and the Norwegian cable manufacturer Nexans.

Billions saved

The heating system has already been brought into use on eight Norwegian offshore fields.

In 2010, Statoil announced that DEH had saved the company billions of kroner on the Norwegian continental shelf.

Eliminates expensive extra pipelines

The oil companies have traditionally sent “anti-freeze” through their pipelines together with the oil, gas and water flow from wells. In long pipelines, this was a continuous process, while in shorter ones it was only carried out during shut-downs.

Extra pipelines were needed to bring the chemicals out to the subsea installations.

Such expensive pipelines are no longer required when the DEH system has been installed. This is the most important factor in reducing costs.