|

|

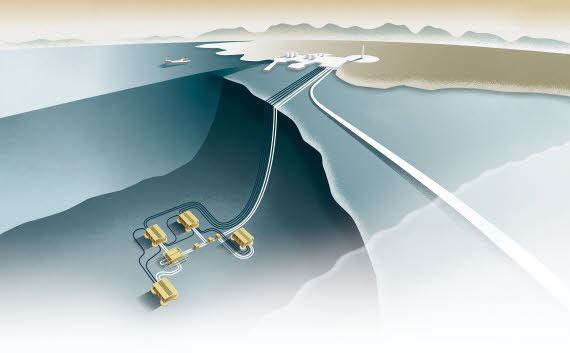

The Ormen Lange project demonstrates how gas can be brought up by pipelines from inhospitable depths where platforms would be too expensive. Illustration: Statoil |

Ormen Lange lies 120 km off Kristiansund. The gas field can meet 20 percent of the UK’s need for gas, and it will supply British consumers for several decades ahead.

The gas from Norway’s first deepwater project is brought to the surface using only subsea technology, and is taken ashore by means of the multiphase technology (carrying oil, gas and water in one and the same pipeline) developed by the Institute of Energy Technology and SINTEF.

Avoids expensive delays

According to calculations made by Hydro, the field developer, a floating production platform and installations on the seabed would cost about the same.

Subsea technology and multiphase transport were chosen partly because approval of a platform-based solution could have led to an expensive delay to the project.

Gigantic marine trench

The pipeline to the coast of the County of Romsdal passes through an extremely hilly trench left by one of the world’s biggest underwater avalanches, and then up the steep slope formed by the avalanche. This part of the Ormen Lange project therefore needed a research effort at national level, to which SINTEF contributed in several areas:

- Model tests carried out by MARINTEK contributed to new design regulations that led to major savings by permitting more and longer pipeline free spans on the seabed.

- Other model trials at MARINTEK saved the project expensive preventive measures following installation of the umbilical cables.

- New numerical methods developed by MARINTEK predicted the extent of large lateral motions of the pipeline while it was being laid. The calculations determined the number and siting of the concrete anchors and stone carpets required.

- A system developed by Statoil, SINTEF Energy Research and the Norwegian cable manufacturer Nexans for direct electric heating of pipelines is in readiness for installation if heating turns out to be needed to avoid ice-like gas hydrates and wax formations from blocking the pipelines.