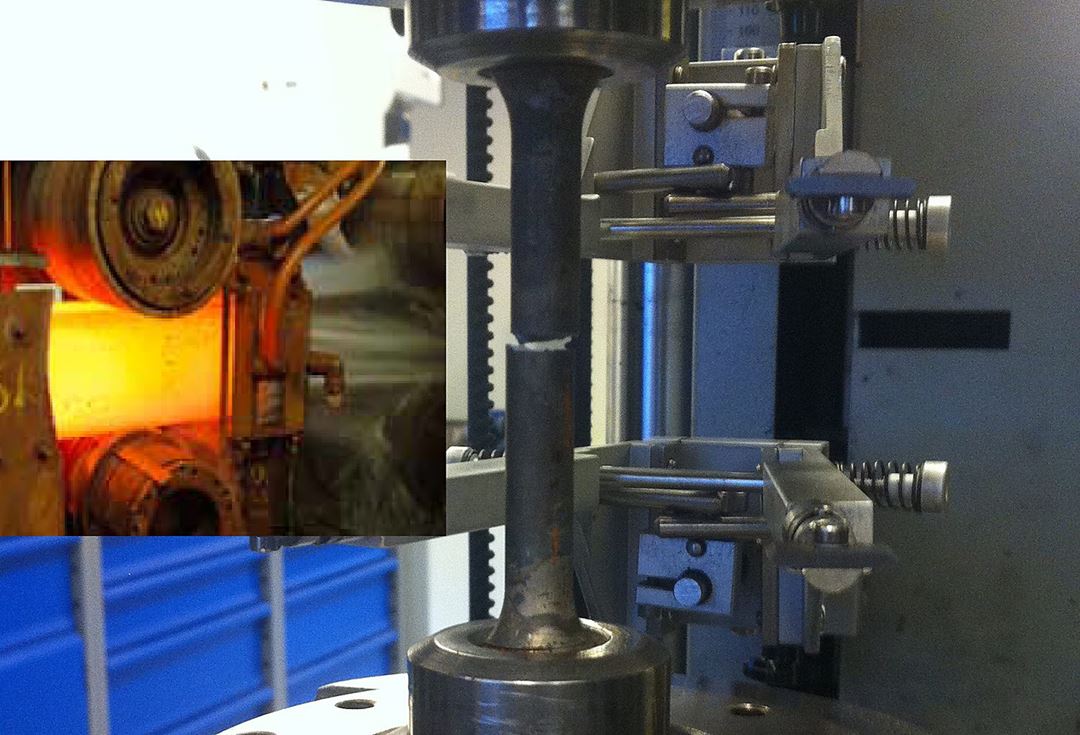

RoHard is a 4-year innovation project within the Norwegian research council program BIA. BIA funds industry-oriented research, and is a broad-based programme that supports high-quality R&D projects with good business and socio-economic potential. The project is based on a partnership between Kverneland (project owner), Nøsted Kjetting, Kongsberg Automotive, Dokka Fasteners, Nammo Raufoss, SINTEF Materials and Chemistry and SINTEF Raufoss Manufacturing (SRM). The common challenge within the consortium is that all have advanced thermo-mechanical manufacturing processes that are sensitive to the quality of purchased raw materials. Firms experience that their manufacturing processes including different raw material qualities sometimes result in unforeseen quality deviations, leading to uncertainty and scrap as a result.

The participating companies have a good general knowledge of their own processes and the response of used materials. However, to realize step change innovations, the understanding of the complex thermomechanical hardening process and interaction between the incoming material and the related manufacturing process need to increase significantly. R & D activities performed by SINTEF will provide a deeper understanding of materials and processes, and will provide a description of the influence of inbound material qualities and process variations on the final products. The achieved understanding will mathematically be described and implemented in simulation tools to support product and process development.

The main objectives of this project are 1) to develop technology that allows companies to be able to reduce the current unplanned wreck production by at least 40%, and 2) to facilitate the development of at least three new products.

Secondary objectives are:

- To develop a specification for inbound materials

- To develop a test technology to characterize material quality and relate process routes

- To develop and customize numerical tools for assessing the risk of geometrical defects / quenching induced cracks

- To optimization the curing process for different materials using numerical tools

- To validate improvement of material and quenching process for specific products

The companies in the consortium have about 1,935 employees in Norway, and production takes place in several communities. All the company's factories have a full array of local subcontractors who will benefit from the enhanced competitiveness of the industrial participants in RoHard. The result of the project will then contribute to secure existing businesses and the creation of new companies. Result from R & D work will be important in future to ensure a continuous knowledge-based development of the industry to ensure competitive advantages.

Contact person and projeckt leader at SINTEF Materials and Chemistry: Dirk Nolte

Contact person at SINTEF Raufoss Manufacturing: Rune Østhus