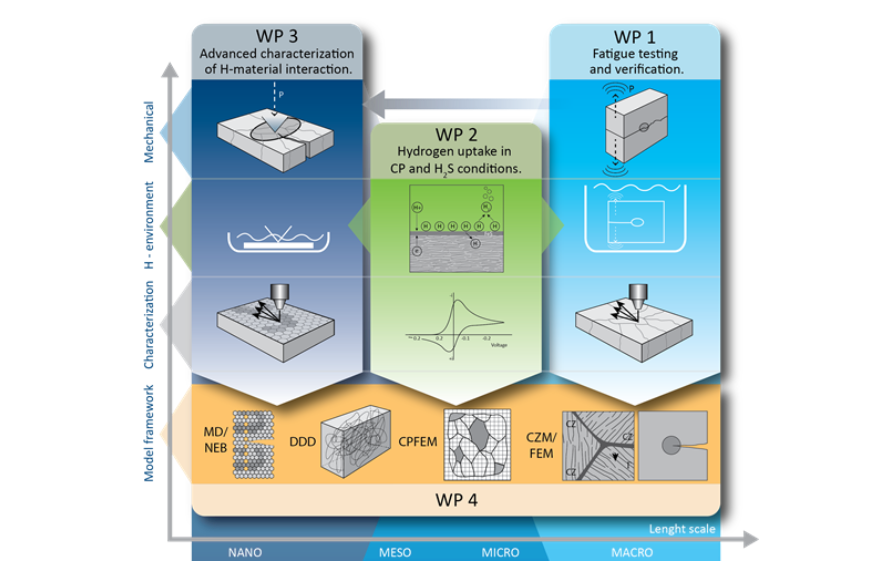

Fatigue crack growth with hydrogen (H) influence under cathodic protection (CP) and H2S conditions will be examined and modelled at length scales ranging from nano to macro. The project aims to investigate, understand and measure the influence of hydrogen on fatigue crack growth. To achieve this, in situ fatigue testing at the macro-scale under hydrogen-charging conditions that are representative of service conditions, combined with advanced nano- and micro- characterization of the cracks and plastic zones will be used. These results will give input to a hierarchical model framework to address the combined degradation effect from fatigue and hydrogen.

SINTEF is the project leader for WP02 Dissemination and communication of the results (V. Olden), WP1: Fatigue testing and verification (A. Alvaro) and WP4: Multiscale modelling of H and materials interaction (V. Olden).

The WP01 will be responsible for the dissemination and communication of the results. Scientific papers in peer-reviewed journals and conferences proceedings are the primary way of disseminating scientific and technical results. Social media will also play an important role in the dissemination of the results to the general public.

The aim of WP1 is dual: to identify the testing parameters and give the samples which will be used for testing and characterization in WP2 and to provide the final verification for of the model framework which will be developed in WP4. Information of hydrogen charging conditions is given by WP2.

1.1 Fatigue crack growth test: Includes standard fatigue crack growth experiments with and without in situ H-charging. Screening of the main testing parameters, i.e. frequency, stress ratio, stress intensity range and load cycle shape, will be performed in this task. Fractography of selected fracture surfaces through optical microscope and SEM will also be carried out.

1.2 Preparation of pre-cracked samples: Pre-cracked specimens with fatigue cracks of appropriate length for advanced characterization and testing in WP3 will be prepared.

1.3 Verification of the model framework: Final verification of the model will be performed by running fatigue testing of fracture mechanics specimens made of pipeline steel in air and H charging conditions.

WP4, will receive quantifiable information from WPs 1-3. One PhD candidate will be allocated to the WP. UdS and PoliMi will co supervise the PhD.

4.1 MD and NEB: This task will provide activation energies for dislocation cross-slip, pair interactions and kink-pair nucleation in presence of H for the DDD simulations.

4.2 DDD: Mesoscopic rules for the evolution of dislocation densities and interaction coefficients between slip systems in the presence of H will be provided. These rules will be used to parameterize the crystal plasticity model.

4.3 CPFEM: The H information from the meso-scale is provided to the micro-scale. The resulting behaviour of dislocations densities in fatigue influenced by H in a microstructure informed model will be then obtained.

4.4 CZM: Transgranular fatigue cracking will be represented by H influenced cohesive elements informed from the previous tasks. Finally, the models will be validated against carefully chosen experimental tests with and without the presence of H.

SINTEF and, NTNUare the research partners in the project. International cooperation with Politecnico di Milano, Italy and University of La Rochelle, France.

Project manager Afrooz Barnoush, NTNU

For more information, see the Project web at NTNU