Research on "green water on deck" and resulting loads on bows and decks of FPSOs is an important area of SINTEF's efforts on behalf of its Norwegian and international clients. During the past few years, we have been working in this field for the Brazilian oil company Petrobras in particular, in collaboration with SINTEF do Brasil.

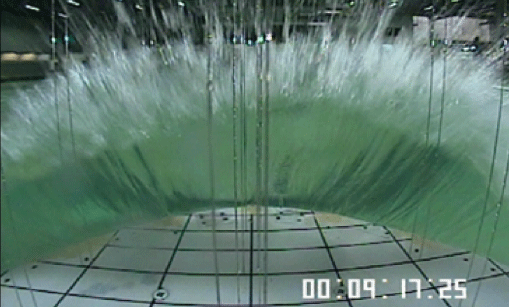

It is well-known that in heavy weather, solid water masses, known as "green water", can flood the main deck of ships. This is more serious for FPSOs than for conventional vessels. It can cause damage to the vessel itself and to special deck installations such as process facilities. Under extreme conditions it can compromise a ship's sea-keeping ability, and it can even put human lives at risk. The growing use of floaters in offshore production in regions exposed to green water increases the focus of the international offshore industry on this problem.

To meet the challenges presented by green water, the industry needs more accurate and efficient numerical tools. This is theoretically complex and requires good validations against laboratory tests, which is an essential aspect of SINTEF's work. An efficient and simplified software tool (Kinema3) has been developed to perform analyses, particularly during early design phases. It builds on basic principles and a good understanding of the physics, as well as accurate empirical knowledge derived from model tests.

For more detailed calculations, in 2012-2013 we also developed a combined tool in which details of deck structures are modelled more accurately using computational fluid dynamics (CFD) methods, closely integrated with experimental verification. This requires a good understanding of physics and numerical methods. Promising results have been obtained in terms of accuracy and computing speed. We have also initiated a complete and detailed CFD procedure that models both the vessel itself and the surrounding waves. Analyses of this sort are still both extremely elaborate and time-consuming, but promising results have been obtained with a view to further development.

Our efforts during the past year have been performed in the context of a project financed partly by the Brazilian oil company Petrobras and partly by SINTEF.