The automotive sector is steadily increasing the amount of aluminium that is used in cars, because of its high strength/weight ratio, good corrosion resistance, high ductility and excellent energy absorption in crash components. Aluminium is infinitely recyclable at just 5% of the energy cost of producing it from bauxite. And energy is just one aspect; the environmental impact of mining, refining, transport and electrolysis of primary aluminium is very high. The global demand for low-carbon, recycled Al products is growing, particularly in sectors like automotive and construction.

There are many levels of recycled aluminium based on purity and the degree of sorting. For example, we distinguish between process scrap, which is relatively pure with a well-known composition, and post-consumer scrap, which is a mixture of many different alloys with many sources of contaminations. Using a lower quality of scrap with less sophisticated sorting is both cheaper and requires less energy. Adapting the processing of alloys to allow for a higher level of trace elements while keeping good corrosion resistance and mechanical strength is the core innovation of RACE.

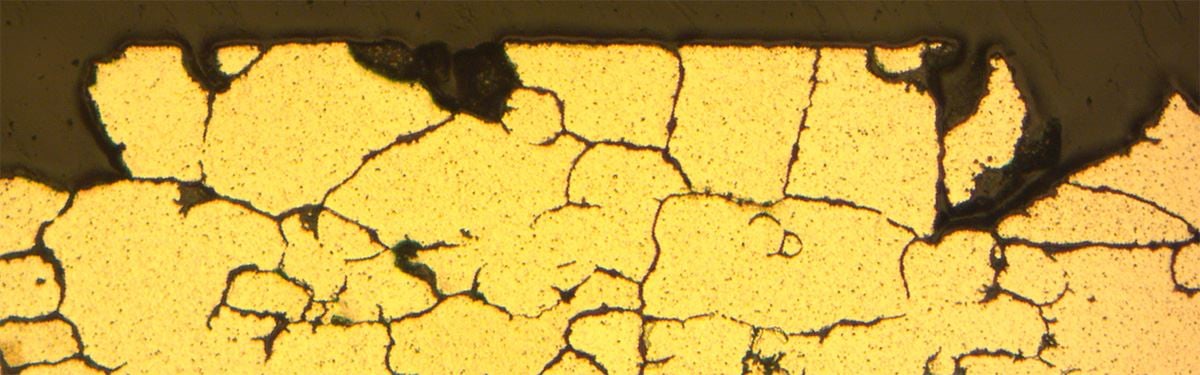

The role of SINTEF is to perform detailed analyses of the structure and chemistry of the materials down to the micro and nano scales, and perform systematic tests of corrosion and strength to relate the properties to features that we know initiate and propagate corrosion attacks.