The new combustor design will be fully retrofittable to existing gas turbines, thereby providing significant opportunities for refurbishing existing assets.

SINTEF leads Work Package 2 (Numerical Simulations) and perform the following activities:

- Numerical assessment and prediction of the effects of H2 addition (up to 100%) on the flame stability and emissions of the second stage of the CPSC.

- Definition and performance of the data sampling necessary for the characterisation of the combustion dynamics response of the CPSC system to H2 addition (up to 100%).

Objectives:

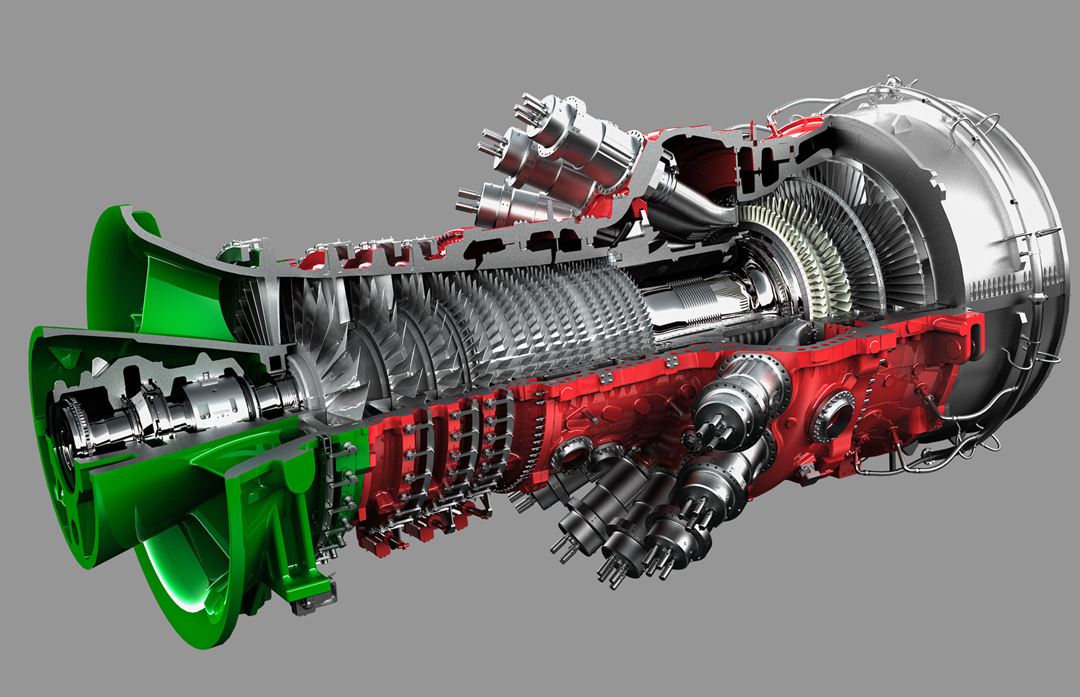

H2 combustion system design and development

FLEX4H2 will develop and validate a safe, efficient and highly fuel-flexible combustion system capable of operating with any hydrogen concentration up to 100% H2, at H-Class operating temperatures, while still meeting emission targets without any use of diluents.

Validation and demonstration

The combustion system will be validated with up to 100% H2 at full gas turbine operating conditions. The full-size combustor prototype will undergo dedicated atmospheric and high-pressure testing up to Technology Readiness Level (TRL) 6.

Pathways presentation

The FLEX4H2 project will provide credible pathways for comprehensive exploitation of the project’s results and thereby providing the basis for a firm contribution to the EU Green Deal towards decarbonisation of the electric power sector by 2030 and beyond.

Impacts:

- Contribution to Net Zero pathway

- Accelerating the transition phase

- New combustor technology

- Efficient grid balancing

- Re-utilisation of existing infrastructure