Project summary

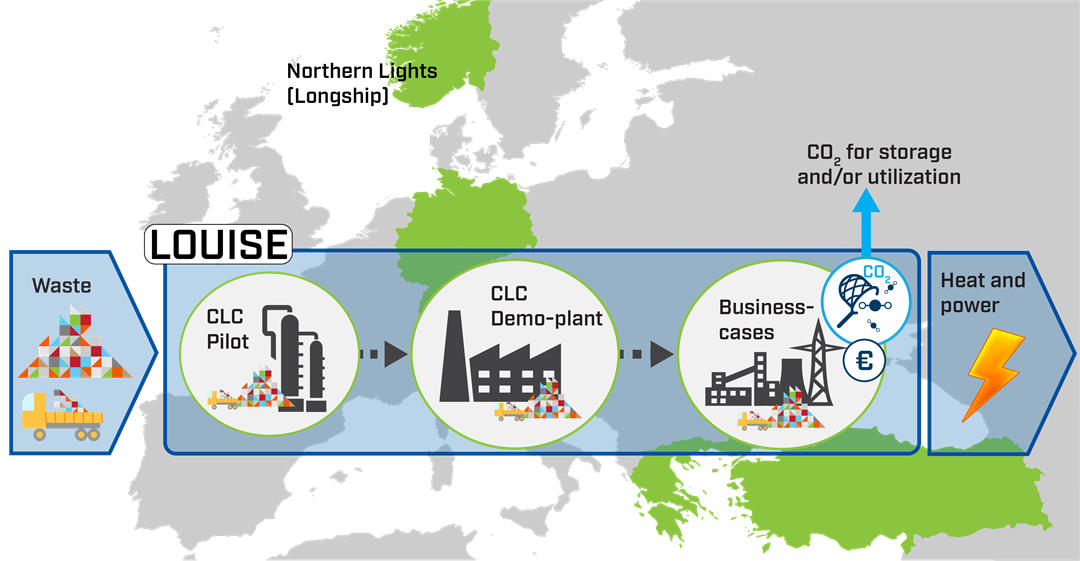

The aim of this project is to prepare for a pre-commercial demonstration of Chemical Looping Combustion (CLC) of solid waste-derived fuel, which is an innovative process for generating power and heat from waste (waste-to-energy, WtE) and producing a concentrated stream of carbon dioxide (CO2) that is ready for transport and storage or utilization.

In CLC, an oxygen carrier transports oxygen from the air reactor to the fuel reactor. When the fuel and oxygen combust, a CO2 rich flue gas is produced without nitrogen (N2). This CO2 can be efficiently separated and purified. It can then be used in one of two ways:

- The CO2 can be stored permanently, leading to a net reduction of CO2 in the atmosphere.

- The CO2 can be used to produce carbon-based added value materials (e.g., methane, methanol, DME, etc.).

This project will demonstrate CLC of solid recovered waste-derived fuel (SRF) through testing in a realistic environment, using pilot tests at a scale of up to 1 MWth (TRL 6). Concepts for using spent oxygen carriers in creating titanium dioxide (TiO2) will be developed, making the processes more economic.

Experiments will be conducted to investigate the interaction of oxygen carrier materials with the impurities in the solid waste-derived fuel.

1D- and 3D-simulation models of the CLC reactors using waste-derived fuel will be developed and validated by pilot data. A basic design of a 10MWth CLC demonstration plant will also be developed.

Business cases will be developed and evaluated for four cases in the different countries involved (Norway, Germany, Turkey and Greece) based on costs (CAPEX, OPEX) and revenues (power, heat, spent oxygen carriers, chemicals, incentives for negative CO2 emissions, etc.), and considering synergies with neighbouring industries. The impact of the full-scale WtE plants on the environment will be determined by life cycle analyses.

Objectives of the project

- To demonstrate chemical looping combustion (CLC) of SRF in a dual fluidized bed configuration, using ilmenite as the oxygen carrier, in a realistic environment (TRL 6), by pilot unit testing at scales of 150 kWth and 1 MWth, aiming for 90% CO2 capture and 90% CO2

- To accelerate the deployment of CLC by providing the basic design for a 10 MWth CLC demonstration plant (TRL 7) for waste-derived fuels, and possibilities for retrofitting an existing fluidized bed boiler, including the required flue gas cleaning / processing steps for CO2 transport, storage, and utilisation.

- To increase commercial attractiveness by reducing CO2 avoidance costs by >7% through exploiting synergies with other industries – in particular, re-using >90% of spent oxygen carrier materials from CLC in the metal processing industry.

- To provide business cases for waste-to-energy (WtE) plants that apply CLC technology, aiming for a net electrical efficiency >35 %, CO2 avoidance costs <25 €/t, and net negative CO2

Outcomes and impacts

This project will investigate the feasibility of using solid recovered waste-derived fuel (SRF) in CLC and demonstrate the technology in a real environment by conducting pilot tests at a scale of up to 1 MWth (TRL 6). It will lay the foundation for a system prototype demonstration in an operational environment by developing a basic design of a 10 MWth demonstration plant (TRL 7). The successful operation of this 10 MWth plant will encourage the realisation of a commercial waste-to-energy plant based on CLC technology around the year 2030.

Assuming that half of the 50 Mt/year of SRF/RDF anticipated in 2050 is used for CLC with 90% CO2 capture efficiency, the potential to avoid CO2 emissions in the EU is as high as 31 Mt/year. Further CO2 reductions are possible if CLC is also applied to other kinds of waste, such as biogenic residues or industrial wastes.

Project owner: TU Darmstadt, Energy Systems and Technology