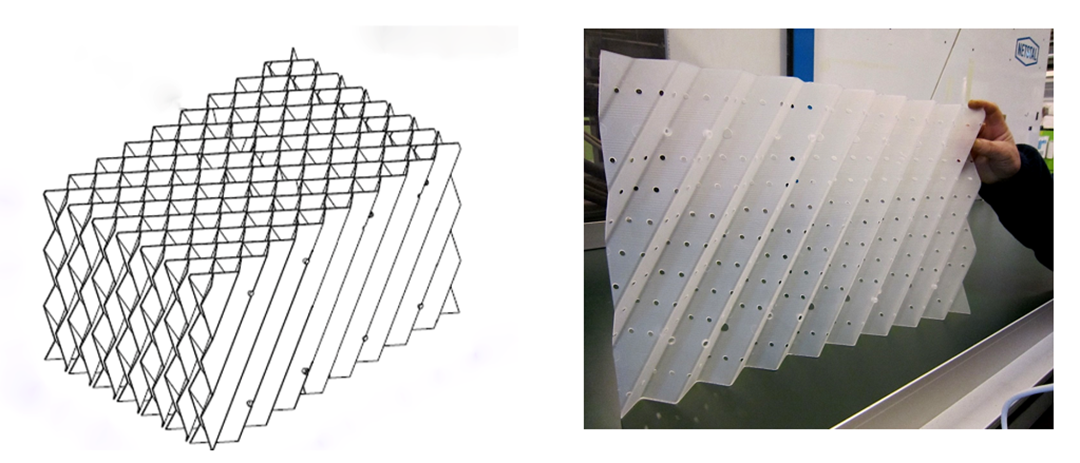

The project focuses on components used in columns for CO2 absorption and desorption (these components are often called "packing"), but the materials in the project are also relevant for other uses in CO2 capturing plants.

Today, plants for solvent-based CO2 capture typically use packing of stainless steel, but polymer-based materials and mass-production methods may reduce the investments costs for such plants. Furthermore, studies indicate that using polymer-based materials may reduce the degradation of common solvents, compared to using metallic materials.

The project performs research on the lifetime of polymer-based materials when exposed to common amine-based solvents. There are also activities on optimizing the geometries and surface properties of packing components, aiming at increasing the CO2 capturing efficiency and/or reducing the operational costs of the plant.

The project is lead by BEWI Biobe with SINTEF as research partner. It is supported by the CLIMIT programme of the Research Council of Norway (grant no. 296428).