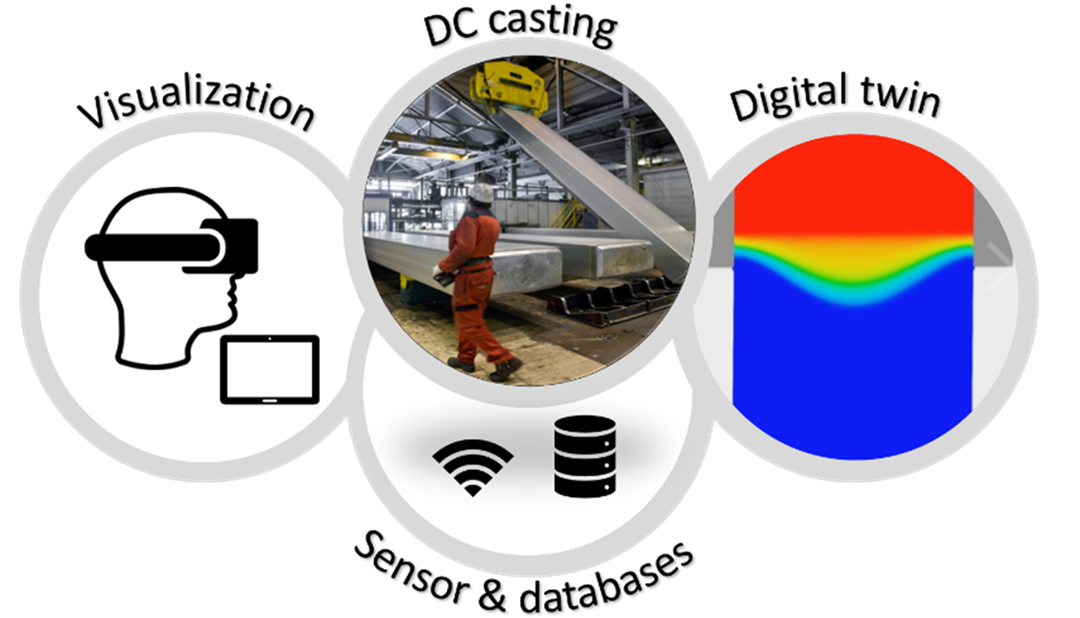

Casting solutions leading to increased process control and enhanced operator working conditions is central in the path towards sustainable production. The Digicast project will be dedicated to developing Intelligent Casting systems for Aluminium DC-casting by combining process know-how in the form of a digital process twin with visualization technologies.

An intelligent casting system will significantly reduce the early phase exploration margins, minimize the risk of operator errors, increase safety and productivity, and improve scrap-rate in the casthouse. Such a system has the potential to significantly reduce the qualification time of new products.

In the research project, SINTEF contributes to the numerical framework for the casting system by:

- Designing and developing digital twins based on physical models

- Testing the accuracy and CPU time of the digital twins

The project is an Innovation Project for the Industrial sector (IPN) financed through Norwegian Research Council's BIA-programme with partners Hydro, Hycast, PointMedia, IFE and SINTEF.