SusOrgPlus is a multi- and trans-disciplinary project aiming at the development of systemic solutions for processing of organic food stuffs, simultaneously catering for resource efficiency, high product quality and utilisation pathways for under- utilised raw materials and the production of novel, value added products. Thus, it will help to increase consumer acceptance, the overall sustainability of the sector and the livelihoods of the producers.

Objective

The main objective of SusOrgPlus is to develop a low-cost smart processing system and to develop a CO2 neutral drying system. The novel control system and drying system will be tested and evaluated using novel natural food additives and organic products.

SINTEF's role

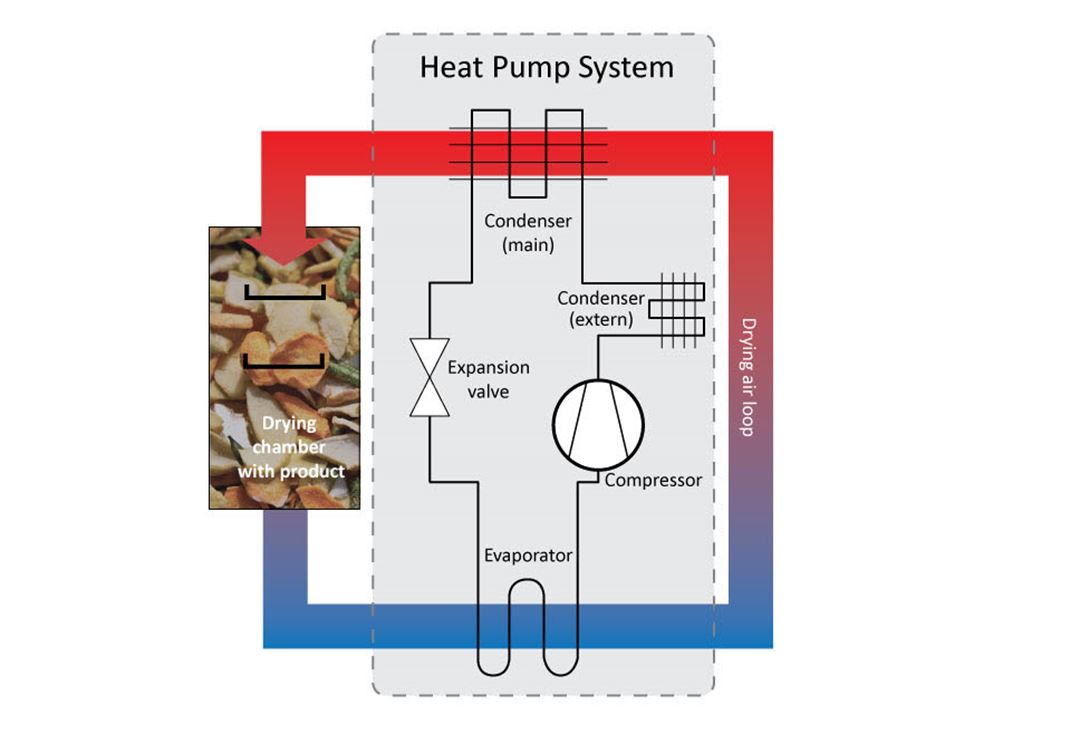

The main activity for SINTEF is the development and demonstration of a CO2 neutral drying system, implementing waste heat recovery through a heat pump system, so called heat pump drying.

The concept of heat pump drying by using natural refrigerants will be demonstrated for an industrial drier. The drying process will be event controlled so that the drying conditions can be improved with respect to product quality and energy efficiency. The SusOrgPlus concept will allow to phase in renewable energy sources in organic food preservation, recover drying energy and reduces the amount of primary energy consumption by up 75%. SusOrgPlus will focus on the development of a market ready drier concept which can be implemented by small or medium sized producers and stakeholders.

SINTEF will use its refrigeration and food technology background in order to demonstrate cost effective, fossil fuel free and carbon neutral food preservation.

The heat pump dryer will recover the waste heat in the cold and moist air, which is leaving the drying chamber, by the evaporator of the heat pump. The same heat will then be upgraded to a significantly higher temperature, so that it can be re-used in the condenser of the heat pump. Hereby the cold drying is re-heated and can again be used as hot drying air. This concept will save approximately 50% of primary energy.

- Do you want to know more? Visit the website of the main project.

- Or download the SusOrgPlus leaflet (PDF)

The project receives financial support provided by transnational funding bodies, being a partners of the H2020 ERA-net project, CORE Organic Cofund, and the cofund from the European Commission.

SINTEF's work is supported by the Research Council of Norway, grant number 286127 – Core Organic Cofund.