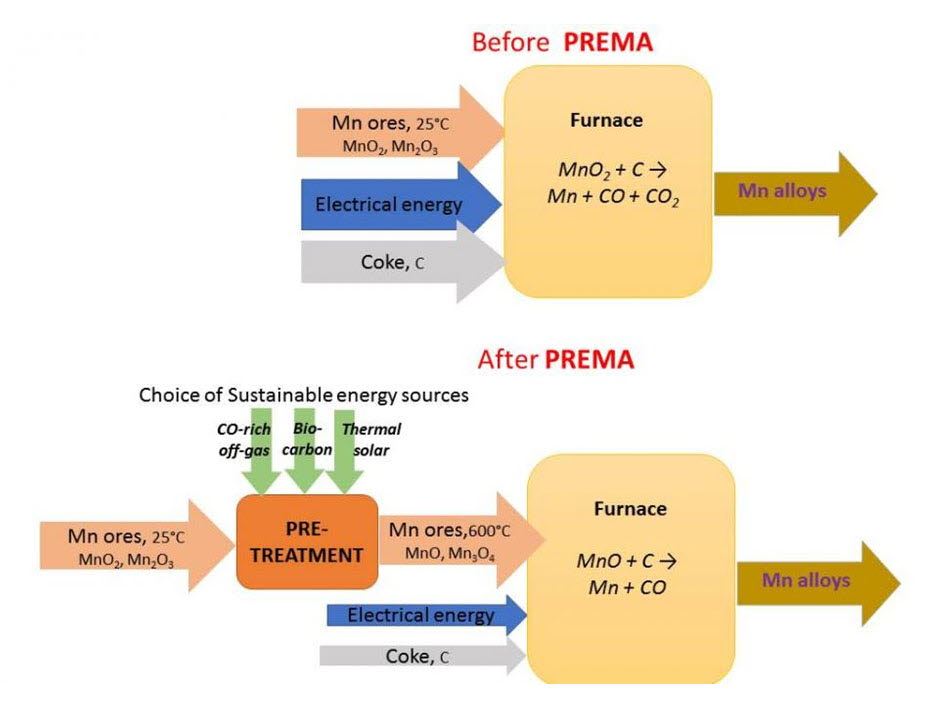

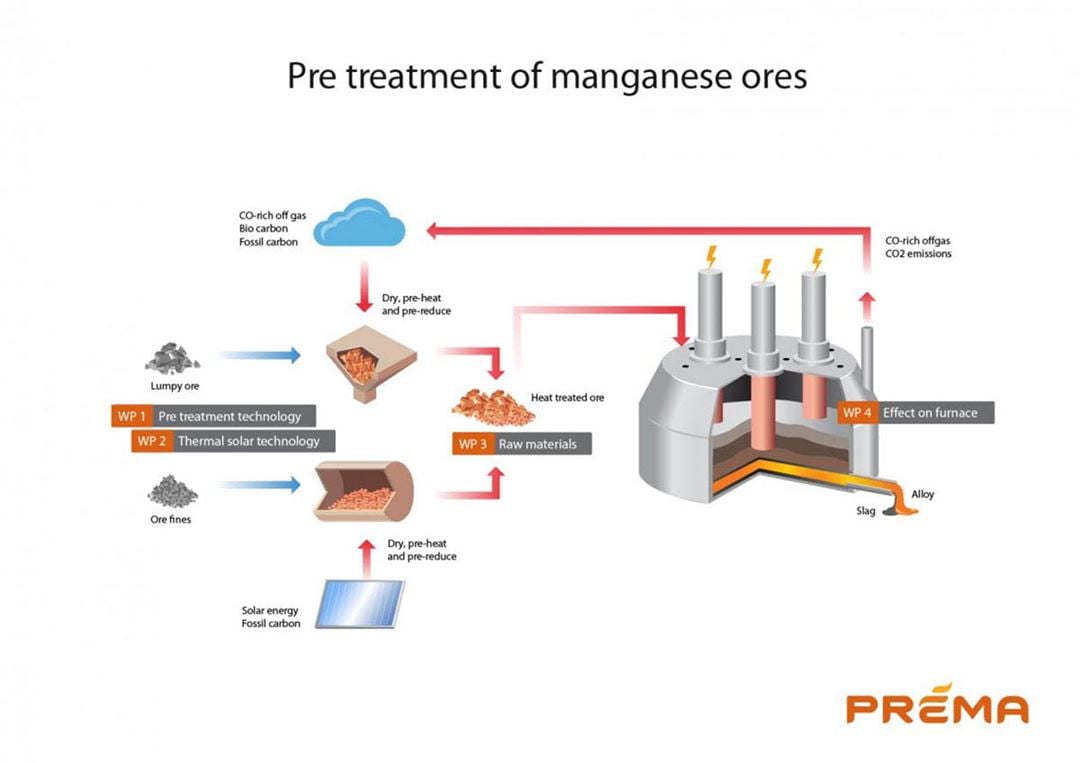

The main concept of PREMA is to increase energy flexibility and allow the use of sustainable energy sources and reduce the overall energy consumption and CO2 emission in Mn-alloy production. This will be done by dividing the Mn-alloy production, today done in submerged arc furnaces (SAF), into two separate units as illustrated below. A pretreatment unit will be added before the existing furnace. Within the project various pretreatment technologies using different energy sources like: CO-rich industrial off-gas, bio-carbon and solar thermal energy will be developed and demonstrated.

Integration of the novel PREMA pretreatment technologies with the process currently used by smelters will lead to a better flexibility in terms of raw materials leading to a 20% reduction in the consumption of fossil carbon, more energy efficient production processes giving a potential for a 20% reduction in overall energy consumption and a global reduction of operation costs by at least 10%. The ultimate ambition of PREMA is to scale the technology up to use in industrial manganese alloy production both in Europe and South Africa.

The overall objective of PREMA is to demonstrate a technology for pretreatment of manganese ores that will enable to increase energy flexibility, energy efficiency, enhance raw material use of fines, and reduce CO2 emissions in production of Mn-alloys.

The above mentioned overall objective of PREMA can be split into the following scientific and technological objectives:

- Produce Mn-alloys in a new two stage process with pretreatment in a separate unit developed in PREMA followed by final reduction to Mn-alloys n a sub-merged arc furnace by current technology

- Provide a technology for pretreatment of manganese ores based on sustainable energy sources and with flexibility in choice of energy source

- Be able to use solar thermal energy as energy source in production of Mn-alloys

- Provide technology suited to pre-treat all actual Mn-sources

- Assess the sustainability and robustness of the developed technology

- Prepare for industrial implementation the developed technology for separate pretreatment of Mn-ores by sustainable energy sources

- Exploit the results of the research, organization of trainings and workshops

Partners:

- SINTEF AS, Norway (project coordinator)

- NTNU, Norwegian University of Science and Technology, Norway

- Ferroglobe Mangan Norge AS, Norway

- Mintek, South Africa

- Transalloys, South Africa

- Stellenbosch University, South Africa

- DLR, the German Aerospace Center, Germany

- OFZ a. s., Slovakia

- Outotec , Finland & Germany

- ERAMET, France & Norway

- HZDR, Helmholtz-Zentrum Dresden–Rossendorf, Germany

- IETU, Institute for Ecology of Industrial Areas, Poland

This project has received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 820561

For more information, see: www.spire2030.eu/PREMA