The project addresses drying applications. The results are however of major relevance for several other energy-intensive industries such as e.g. pulp and paper industry.

SINTEF's role

SINTEF is responsible for the open loop heat pump in which a novel lubrication free turbo-compressor technology is used to recover energy from a steam based drier by the help of Mechanical Vapour Recompression (MVR).

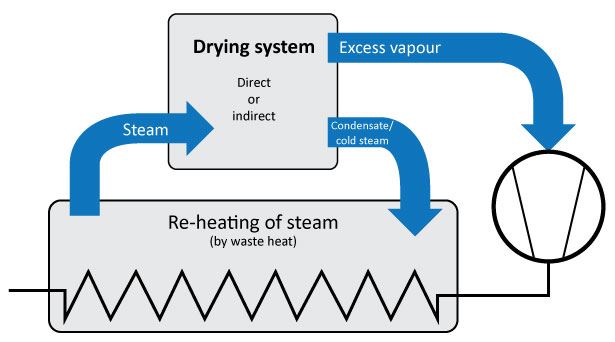

MVR does not generate steam as regular high temperature heat pumps but recompresses steam from the core processes such as steam drying. In steam drying, wet products enter the drying system, together with hot steam. The high temperature steam warms up and evaporates the water within the product. The cooled steam exits the dryer, while the smaller excess stream is compressed to a higher pressure with the MVR compressors. Now, the high-pressure steam is condensed in a heat exchanger, herby re-heating the process steam which then can be used again as drying agent. Implementing MVR in dryers and evaporators often reduce the energy requirement by 60-80%.

The novelty of the DryF solution is that the achievable pressure ratio of the turbo-compressors is significantly higher than conventional technology. At the same time the system is much more compact due to the usage of DC-motors and technology. With this development it is possible to achieve a pressure ratio of up 6 in a two stage system.

In order to achieve the targets of the open loop case SINTEF is cooperating with 3 industrial partners from Scandinavia. The turbocompressor prototype is built by the Rotrex A/S (Denmark) and the open loop heat pump system is delivered by Epcon Evaporation Technology AS (Norway). The concept will be demonstrated at an industrial drying system of Scanship ASA (Norway).

Why would you want to use the DryF concept?

With the DryF concepts it is possible to reduce the primary energy consumption by up to 80%. For the steam dryer this means that the specific energy consumption per ton of evaporated water is reduced from around 800 kWh to 200 kWh. At the same time the energy supply becomes completely free of fossil fuel and the drying process does not create any climate gas emissions. This is money saved and climate friendly at the same time!

Principle concept of the open loop case of DryF, based Mechanical Vapour Recompression.

DryF is a four-year Innovation Action project funded by Horizon 2020 Research & Innovation Framework Program under the Energy Efficiency 2016 - 2017 call and "Valorisation of waste heat in industrial systems (SPIRE PPP)" topic. A consortium of 12 partners made of 2 research institutions, 3 SMEs and 7 large industrial companies is addressing the specific challenge that Resource and Energy Intensive Industries (REI) produce significant amounts of waste heat currently being lost.

Energy and fuels represent between 20% and 40% of the production costs in several of these industries and produce large amounts of CO2 emissions. DryFiciency aims to improve energy efficiency by designing, building, testing & demonstrating high temperature heat pump systems applicable to these industries.

Do you want to know more? Check out the other demonstration cases.