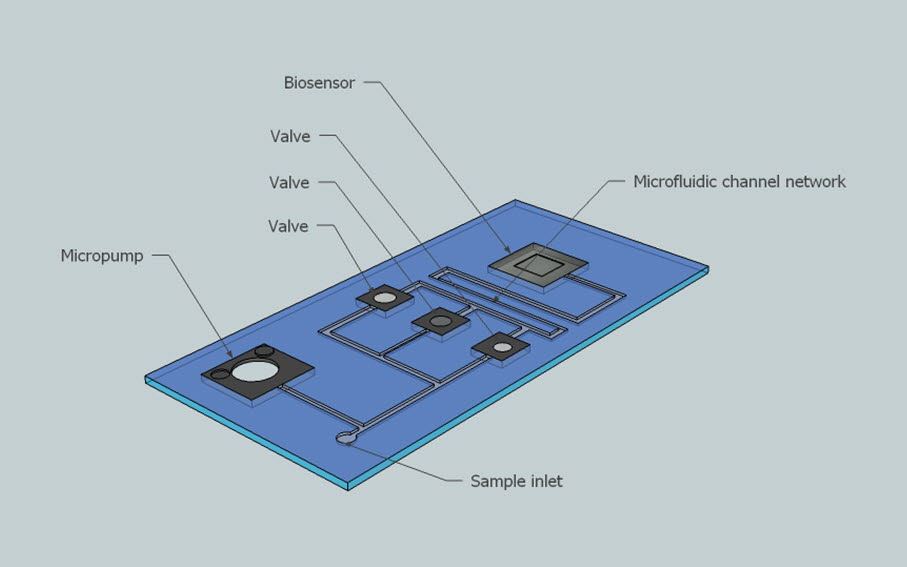

The project is in the field of fabrication of microfluidics-based lab-on-a-chip devices, e.g. for in-vitro medical diagnostics. Such a lab-on-a-chip is a miniaturised system in which small volumes of fluid are transported between various stations for mixing, performing chemical reactions, detecting certain molecules etc.

In short, the project deals with a new method for coupling fluid channels in a polymer chip with channels in a silicon chip. Couplings obtained with the new method enable a substantial extension of the functionality of a lab-on-a-chip, in a compact and autonomous unit.

The new method makes it possible to combine the advantages of injection moulded polymer chips with the unique functionalities that can be obtained with a micro/nano machined silicon chip.

The potential customers for the new method are companies that develop and/or produce systems for in vitro medical diagnostics or monitoring. This is the life science industry, but also companies that produce silicon-based components, or companies that produce lab-on-a-chip units, e.g. by polymer injection moulding and various assembly processes.

The new method can also be used for other microfluidics-based devices, in which micro/nano structured silicon chips are integrated or encapsulated in a polymer material, e.g. sensors implanted in the human body or micro bubble generators used in ultrasound diagnostics.

The status at the start of the project is that SINTEF has made a demo product which demonstrates the new production method, as well as the new functionality that can be obtained with this method. The project will be used to verify the new method for a realistic commercial product (more complex than the demo), and with regard to upscaling to industrial production.

The project is a collaboration between SINTEF Materials and Chemistry, SINTEF ICT MiNaLab and SINTEF TTO.

This project (supported by the Research Council of Norway via the FORNY programme) aims to verify a new industrial production method (patent applied for by the project applicant SINTEF).