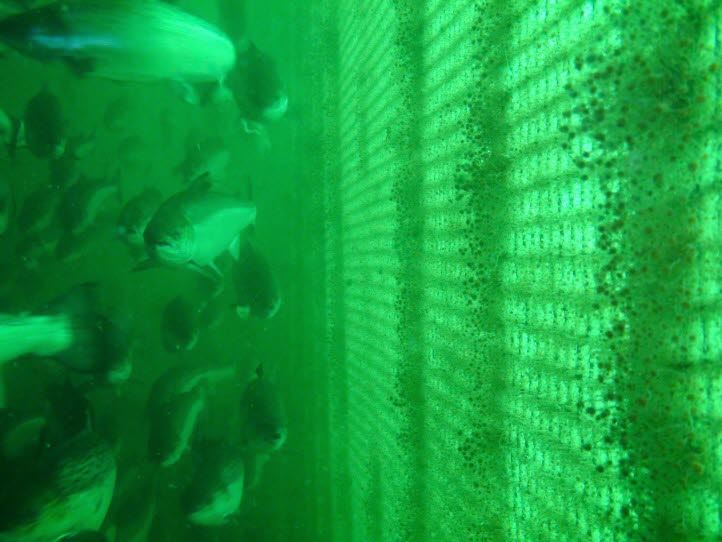

Biofouling, the unwanted growth of organisms such as algae or mussels, growing on the nets of salmon cages is a multifaceted problem in Norwegian aquaculture. Biofouling is especially challenging since the Norwegian salmon industry relies on cleaner fish to reduce the number of salmon lice on the cultured fish. However, given the chance, the cleaner fish prefer to feed on biofouling instead of the lice, resulting in increasing lice numbers in cages with biofouling growth.

The most common antifouling strategy employed in the Norwegian industry is the use of copper coated nets that are regularly cleaned by high-pressure washers. Unfortunately, today's cleaning technologies are lacking efficiency. One of the problems is that high-pressure cleaning leads to abrasion of the copper coatings, potentially impacting the environment, and is not compliant with the Aquaculture Stewardship Councils (ASC) Salmon standard. In addition, there is strong suspicion that waste material released during cleaning can damage the gills of salmon.

Brynsløkken AS, supported by a consortium of research partners and the Research Council of Norway, is aiming to develop new net coatings in combination with 'matching' cleaning technologies and operational procedures. The main focus of the innovative project is the development and evaluation of four alternative cleaning concepts.

The chosen technologies have the potential to clean:

- without harming the coating

- more efficiently in order to prevent fast regrowth of biofouling organisms and to reduce the required frequency of net cleaning

- without the discharge of cleaning waste that can compromise fish health

- more time and energy efficient

- in compliance with the ASC standard

This project will also produce concepts for industrial upscaling of the novel technologies and a best practice guide for salmon cage net cleaning.

What have we done?

The first task in the project was to conduct a survey among farm site managers in order to obtain a better overview of the biofouling situation and current biofouling maintenance strategies in use in the Norwegian salmon aquaculture. The results showed that biofouling is indeed perceived as a challenge that impacts many aspects of salmon farming. Furthermore, there is a large amount of knowledge available at the farm level that could be collected and summarised more effectively at the company level. This knowledge could be very helpful in evaluating and improving current biofouling maintenance strategies. At the same time, the survey pointed out areas where more research is needed, and where farmers could profit from more information.

We conducted extensive field testing of 3 alternative cleaning technologies (low-pressure cleaning, cavitation cleaning and suction cleaning) to compare the cleaning efficiency and the impact on the net and coating to effects of high-pressure cleaning. Preliminary results show that cavitation cleaning can be similarly effective in removing biofouling as high-pressure cleaning. Low-pressure cleaning was less effective and suction cleaning had very low efficiency. High-pressure cleaning was very abrasive to the copper coating on the nets and reduced the average coating cover by 21-31 % after a single cleaning event, and 82-90 % after repeated (35x) cleaning events. Low-pressure cleaning was less abrasive, and removed 5-9 % and 40-46 % of the coating after a single and repeated cleaning events, respectively. In contrast, cavitation cleaning had no impact on coating cover after a single cleaning event, and only very little (4-9 %) after repeated cleaning. None of the tested methods had a negative impact on net strength. According to these preliminary results, cavitation cleaning may offer a less abrasive yet similarly effective alternative to high-pressure cleaning.

In the last phase of the project, we are now conducting the final analyses of the data. Furthermore, we are evaluating the tested cleaning methods for upscaling to a commercial level.