SINTEF have worked together with The Norwegian Ferroalloy Producers Research Association (FFF) and NTNU on NOx reduction strategies for more than 15 years. The work is funded by the Norwegian Research Council.

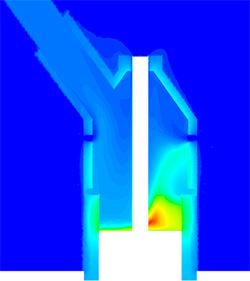

Improved understanding of the NOx formation mechanisms and complete quantitative data for significant reactions is important. Continuous efforts on trying to understand the NOX formation mechanisms in the furnaces have shown that furnace design and furnace operating procedures influence NOx emissions. It is now possible to decrease NOx emissions without large capital investments such as gas cleaning systems and new process equipment. NOx emissions are halved by optimized furnace operation. By optimization of design, further reductions can be achieved. This is proven in industrial furnaces at e.g. the Elkem plants at Thamshavn and Salten. Main cooperation partners in this work are The Norwegian Ferroalloy Producers Research Association FFF, including Elkem, Finnfjord, Fesil and Wacker. The work includes pilot scale experiments, comprehensive industrial off-gas measurement campaigns and CFD modeling.