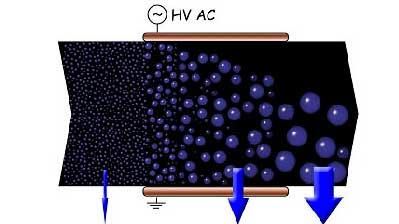

As the sedimentation speed of water drops increases with the square of the drop diameter, the tank sizes can be reduced if one can get small drops to coalesce into larger drops. Electrodes – often used with high voltage (HV) dc or pulsed dc voltage – have been introduced into the sedimentation tanks to augment the coales-cence; in many cases without any improvement at all. The mechanism active in the electrocoales-cence process still remains in the dark.

The New Technological Concept

The project is started on the basis of experience and theories that one – contrary to the common opin-ion - can use ac voltages and turbulent flow in electrocoalescers, and that this offers possibilities for more compact design of the equipment:

- The effects originate from charges on the conductive water drops carried by insulating oil induced by the applied ac field.

- When two drops get close, the drop pair will align with the electric field and a strong electric field and attractive force will occur between these drops.

- The field augments the coalescence process e.g. by creating surface instabilities, keeping the drops in contact, thinning the surface layers at the interface or creating electric discharges.

- Turbulent motion in the liquid results in frequent collisions between drops.

- The fact that ac voltage is used, and that the charges are induced on the drops (no net charge) al-lows for using electric insulation on the electrodes, thus avoiding breakdown from water “plugs”.

- Energy consumption is low.

- Avoiding chemical demulsifiers, decreasing discharges of chemicals to waste water.

Project Challenges

It has been shown that the technique can be very efficient; i.e., increasing drop sizes to the tenfold after being subjected to electric ac fields just for some seconds. However, the nature of the process involved is not understood. The aim of the project is to establish a basic understanding of the electro-coalescence mechanism(s), and to study how the efficiency of electrocoalescers may depend on e.g.:

- Voltage magnitude, waveform and frequency.

- Liquid flow (velocity and turbulence).

- Crude quality (asphaltene content, surface tension, conductivity, salinity in water phase, etc).

It is known that the forces responsible for the coalescence also may result in drop instabilities and fragmentation. One therefore needs theories for optimizing design and operation of equipment.

The project will be developed along two axes. First, one will perform experimental studies using optical and electric diag-nostics to study what occurs between adjacent water drops. Second, simulations and models of multidrop behavior in liq-uid flows will be developed. This brings SINTEF Energy Research and the Ugelstad Laboratory at the Norwegian Univer-sity of Science and Technology together, working on electro-technical materials, hydro dynamics and emulsion technology.