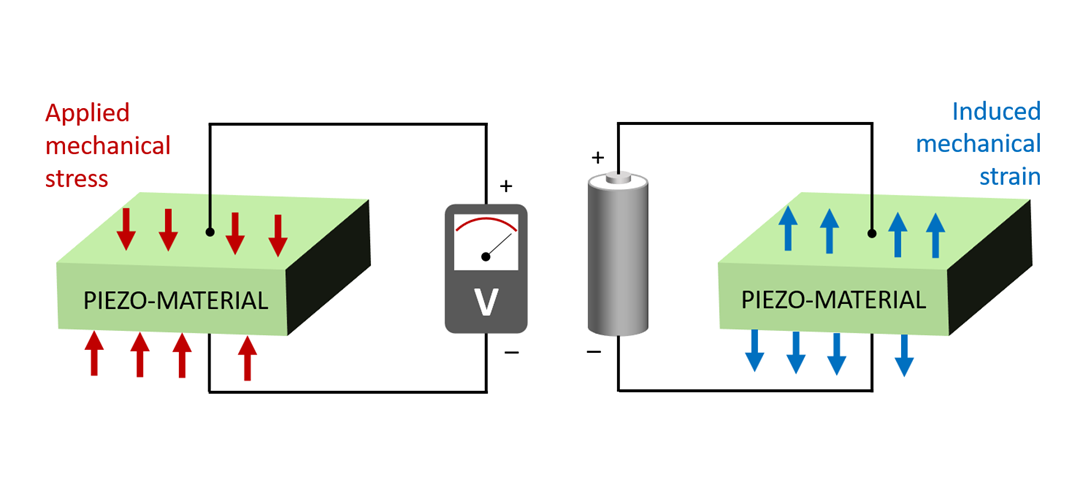

Certain materials become electrically polarized when subjected to mechanical pressure. This is called the piezoelectric effect, and its origin is related to the occurrence of electric dipoles in the material. Depending on the type of application, piezoelectric materials can be utilised in two different ways:

- An electrical polarisation can be generated by applying a mechanical stress to the material. This is called the direct effect and is often used in sensors.

- A movement, strain or mechanical force can be generated by applying an electrical field. This is called the converse effect and can be used in actuators.

A component that utilises both the direct and the converse effects is often called a transducer. A transducer can act both as a sensor, receiving a mechanical signal, and as an actuator, creating a mechanical movement or emitting a sound wave.

SINTEF offers expertise on piezo-materials applied for a wide range of applications. The materials can be shaped as for example thin films, plates, discs, arrays or multilayer structures. When applied as thin films, the materials are usually deposited on silicon wafers. The piezoelectric thin films can be patterned and micromachined by state-of-the-art methods such as lithography and etching.

Today's most commonly used piezo-material is the oxide lead zirconate titanate (PZT). Due to the toxicity of lead-containing compounds there is a general awareness for replacing PZT with environmentally sound lead-free materials. EU has passed several regulations to protect humans and the environment from hazardous substances in electrical equipment, the most important being restrictions of the use of such substances (RoHS directive, "Restriction of Hazardous Substances in Electrical and Electronic Equipment") and the handling of waste (WEEE3 directive, "Waste of electrical and electronic equipment"). Due to the lack of replacement materials and the importance of piezoelectric devices for society, PZT has a time-limited exemption from this limit.

The EU is working on a revision of the RoHS directive and it is unclear how long ultrasound materials will retain the permission to use lead. Therefore, there is great interest in research to find replacements for the lead-containing piezoelectric materials. Recently considerable advances have been made in the development of new piezoelectric materials without lead, that can replace PZT. SINTEF is engaged in this development with partners in Norway and abroad.

Projects/links: