Research Manager Fabrice Lapique at SINTEF Microsystems and Nanotechnology is elated over the confirmation he has now received in writing from Dr. Nino Bolla who sits on the CMS Collaboration, which first published the discovery.

“For us at SINTEF and MiNaLab, this is a big feather in our caps”, he says.

Layer upon layer

Cern near Geneva is well known for its 27 kilometre-long circular subterranean tunnel in which protons circulate in opposite directions reaching velocities close to the speed of light.

There are four large detectors located around the ring, including the two primary devices, Atlas and CMS, which discovered the new particle in July this year.

“CMS is made up of layer upon layer of silicon detectors”, says Senior Researcher Thor-Erik Hansen. “In one of the innermost layers, close to where the particle collisions occur, there are four discs equipped with silicon radiation detector chips” he explains. “To of these discs are equipped with SINTEF chips”, he adds.

|

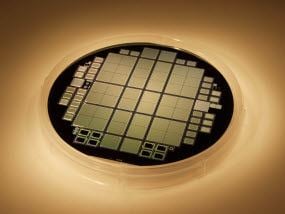

| A disc containing radiation sensors prior to sawing. Photo: SINTEF |

Hansen says that the Norwegian detectors take up no more than between half and one square metre of the total area, which is several thousands of square metres. However, SINTEF can still boast of having one of the most advanced sensors in the world.

Most advanced

“Our radiation sensor is an exclusive and sought-after component for industries supplying advanced instruments for materials analysis”, says Hansen.

“It consists of a double-sided microstructure manufactured on silicon wafers. It is complex and difficult to make. We are currently one of only two or three suppliers of such sensors in the world”, he says.

This little device measures no more than 8 x 8 millimetres, but it takes twenty weeks to manufacture – a process which has to take place in a “super clean” environment.