|

Part of the ECOWAT process consists of turning water into crystals that resemble ice. Each of these five people has played a part in creating the foundations on which the company is based. From the left: Investment manager Jostein S. Bjøndal, Sinvent, inventors Tore Skjetne (founder), Are Lund and Roar Larsen, all from SINTEF, and chairman of the board Joar Welde, a partner in Viking Venture. Photo: Svein Tønseth |

ECOWAT goes in the opposite direction, drawing pure water molecules out of the contaminated water.

Avoids problem other methods suffer from

“The less contamination that remains in the water, the more will traditional purification methods struggle to make the water completely pure. But we don’t have this problem; the less contamination left in the water, the more efficient is our technique,” explains former SINTEF scientist Tore Skjetne.

He is the “father” of the concept behind the new water purification method, and managing director of ECOWAT AS.

Others need large units

Water-soluble contaminants have always been a headache for water purifiers, whether we are talking about formic acid from silos, household detergents or oily water from oil-wells.

At present, very large units of equipment are needed to remove such compounds from water. And if the water has to be ultra-purified, as the pharmaceuticals, food and cosmetics industries require it to be, energy-intensive distillation has been the only way to obtain it.

Smaller, less energy-intensive equipment

The advantage of the technology that ECOWAT AS in Trondheim is about to industrialise is that it is based on smaller, less energy-intensive systems.

ECOWAT intends to concentrate in the first place on industrial clients who require ultra pure water for technical purposes.

From water molecules to solid matter

The purification method is based on transforming water molecules into solid matter that resembles ice – but which is NOT ordinary ice, for lumps of ice would be capable of growing to such a size that they would rapidly block the pipes in a water purification system, hence, stopping the flow.

Utilising hydrates

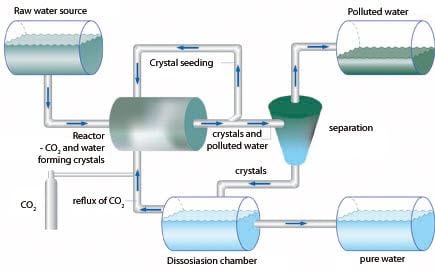

Instead, SINTEF has utilised the ability of the water molecules to turn into what is known as gas hydrates, which are compounds that form when molecules of gas meet water molecules under particular conditions of temperature and pressure.

SINTEF has based its water purification technology on bringing carbon dioxide gas into the contaminated water at high pressure and low temperature.

|

Viking Venture, represented here by partner Joar Welde (right) has great faith in the water purification technology that Tore Skjetne is on the point of industrialising. The process turns water into crystals that resemble ice. Photo: Svein Tønseth |

Like ice itself, hydrates are crystals, and crystals are popular in purification technology, being natural structures whose molecules form regular matrices that exclude contaminants.

The water and CO2 molecules grow together into tiny spherical snowflakes – without the water droplets becoming enclosed in the crystals. This makes the hydrates resemble dry snow, and dry snow does not form snowballs that could block the pores in the purification plant.

Centrifugation and thawing

The next stage in the process is to separate the “hydrate snow” from the contaminated fluid by e.g. centrifugation.

When the hydrate snow thaws, most of the CO2 evaporates and can be reused in the process.

Pure water for gas turbines

The first application that ECOWAT is aiming at is the production of pure water for use in gas turbines on offshore installations, in order to reduce their emissions of greenhouse gases.

If the combustion temperature in gas turbines can be lowered by means of steam consisting of tiny water droplets, the turbines’ emissions of environmentally damaging NOx gases can be reduced by as much as 70 – 80 percent without any loss of power generating capacity.

Water for use in this context must be ultra pure in order to prevent contaminants from burning themselves onto the turbine blades and damaging them.

Helps meet environmental goals

ECOWAT’s ultra pure water will thus help Norway to meet important environmental goals. By signing the Gothenburg Protocol, Norway has committed itself to reduce its NOx emissions by 29% relative to 1990 levels by 2010.

“Our aim is to be able to supply water for use in offshore turbines in 2010,” says Tore Skjetne. “This sector alone is a billion Norwegian kroner market.”

ECOWAT is owned by Viking Venture (43%), SINTEF Venture (40%) and the founder Tore Skjetne himself (17%).

|

How ECOWAT’s water purification technology works. Illustration: SINTEF Petroleum Research |

.

By Svein Tønseth |