|

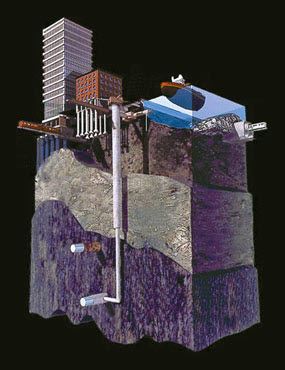

A cross-section of the ground below New York. On the left is the subway, 30 - 50 feet below the surface, while the water supply tunnels lie at depths of 100 to 400 ft. Illustration: Don Foley, National Geographic Image Collection. |

SINTEF tests the samples in specially built apparatuses, and the scientists send back the answers that tell the construction companies in New York just how fast their tunnelling machines can work in each particular type of rock, and how often the cutting heads will need to be replaced.

Huge drills under a huge city

Far below the world metropolis, an enormous boring machine is cutting its way through the schist, granite and gneiss on which New York stands.

The excavations will give the New Yorkers the third water tunnel they so badly need and will make the water supply of the metropolis more reliable. The new supply channel will mean that the city’s two existing, and ageing, water supply tunnels can be repaired whenever necessary.

Guarantee against unpleasant surprises

Operations on “City Water Tunnel No. 3” began in 1970, and will last until 2020. The huge underground project no longer uses dynamite. In its place has come full-profile boring, which means that an enormous tunnel boring machine mills out the rock mass that has to be removed.

Within a short time, a similar machine will begin to bore an extension of the New York underground mass transit system - the Metro. Line 7 is due to be lengthened in connection with an urban renewal scheme in Hudson Yards on Manhattan’s West Side - the first expansion of the city’s Metro System since 1930.

SINTEF is involved in both of these construction projects.

Specially designed test equipment

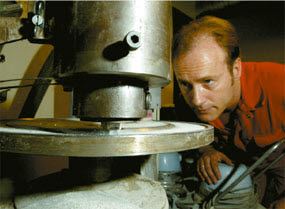

The rock samples from New York are drilling cores that are one to one-and-a-half metres long and five to six centimetres in diameter. The first thing that SINTEF does is to prepare the samples by sawing out small discs from the cores, before what is left is crushed and sieved into a range of different particle sizes.

Then the stone is tested in specially built apparatuses that measure its surface hardness, its resistance to crushing and the wear that it produces on the cutting heads on the boring machine.

|

SINTEF's Filip Dahl is investigating rock samples from the subsurface of Manhattan. Photo: Rune Petter Ness |

Preventing court cases

The test results will be fed into a computer model developed by NTNU/SINTEF. The scientists use the model to calculate how rapidly the boring machine can drill through the rock, and how long the cutting heads at the front of the machine will last before they have to be replaced.

These data are of vital importance in the information that the city authorities provide when they invite contractors to tender for the projects. God prognoses for drilling rates and cutting head lifetime help to prevent construction projects from ending up with cost overruns and court cases.

When the cutting heads have to be replaced, the whole boring process stops and the machine is drawn back from the cutting face. But the taximeter keeps on running - fast!

Feather in our cap

It is a feather in SINTEF’s cap that these rock samples are being sent half-way round the world to Norway for analysis. The test methodology and computer models are the result of more than 30 years of research and development at SINTEF and NTNU.

“Our most important competitive advantage is that we have analysed almost 3000 rock samples by these methods in the course of the years”, says laboratory manager Filip Dahl at SINTEF Building and Infrastructure.

Treasure chest

Fine test results from the laboratory are not worth much if they cannot be related to what actually happens in the real world, so SINTEF and NTNU are making sure that the data from the actual drilling process are compared with the results from the test laboratory.

This has given the two institutions a unique opportunity to identify relationships that can tell us what the values measured in the laboratory mean for boring rate and cutting head lifetime.

“The database that we have built up from our 3000 samples is our treasure chest”, says SINTEF’s Filip Dahl.

By Christina Winge and Svein Tønseth