The visit was an opportunity to see how the laboratory’s equipment is used to study the effects of hydrogen on metals—a key challenge in developing safe and reliable hydrogen infrastructure. The laboratory is part of SMART-H, a Norwegian research infrastructure for investigating how hydrogen impacts different materials, operated by SINTEF and NTNU, and fully financed by the Research Council of Norway.

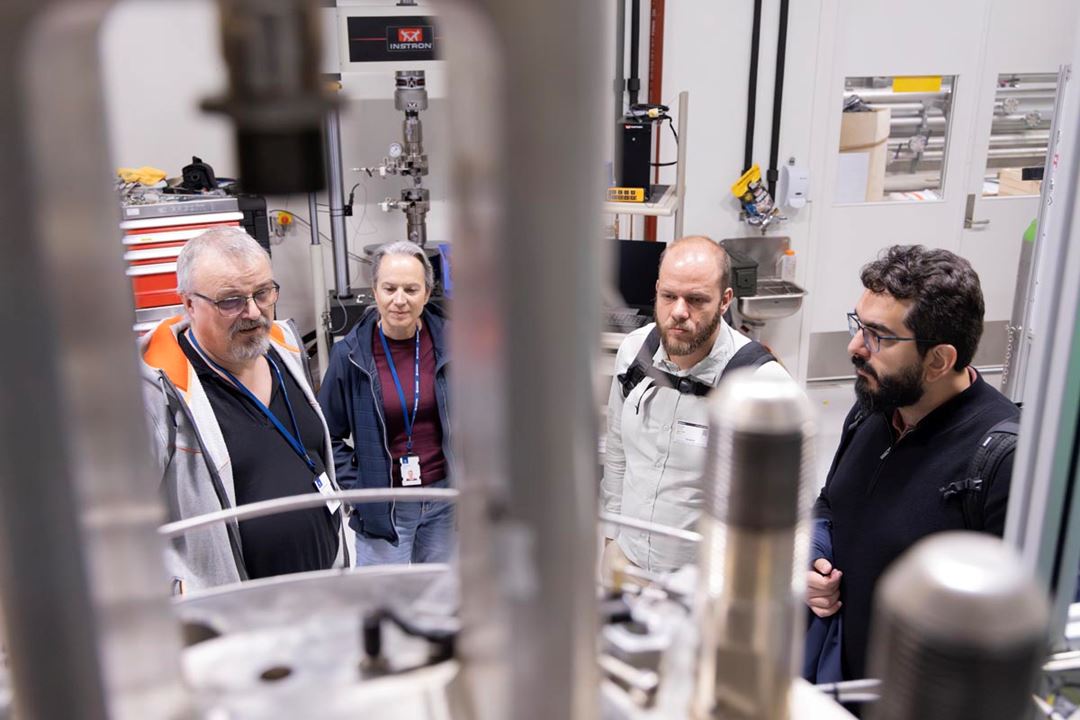

The visitors, Mechanical Engineer Luis Guilherme Tomba Silveira Leite and Equipment Engineer Daniel Correia Freire Ferreira, were guided by Senior Research Scientist Vigdis Olden and Research Engineer Asle Olav Hellesvik from SINTEF. Petrobras are the newest partners in HYDROGENi, the SINTEF-led Centre for Environment-friendly Energy Research (FME) on hydrogen, in which, Vigdis leads the material integrity work package.

A central focus of the visit was the ongoing research into hydrogen and materials interaction. When hydrogen comes into contact with metals, its small and reactive atoms can enter the metal structure. Over time, this can weaken the material and make it more likely to crack under stress – a phenomenon known as hydrogen embrittlement. Understanding this process is important for designing components that will be used to transport and store hydrogen safely.

During the tour, the Petrobras team saw two hollow specimen testing rigs, which are used to test how metal components filled with pressurised hydrogen respond to being stretched or pulled apart. They also received a detailed explanation of the high-pressure gas mechanical test rig. In this setup, hydrogen gas is applied at high pressure to the outside of a test specimen, while mechanical loads are applied to simulate real-world conditions.

"Since this laboratory is 100% financed by the Research Council of Norway, the activity here is currently mainly related to research projects," she commented. "But we do see that many industry partners are eager to get access to this and similar facilities to carry out more industry-related investigations. There is still much to learn about the interactions between hydrogen and materials."

The Petrobras team also took the opportunity to visit the Nano/micro Mechanical Laboratory and Corrosion Laboratory at the Department of Mechanical and Industrial Engineering, NTNU. These labs are equipped with state-of-the-art in-situ nano- to mesoscale mechanical testing and characterisation instruments, which are particularly well suited for research on corrosion and hydrogen embrittlement. Potential collaborations between Petrobras and NTNU were also discussed during the visit.