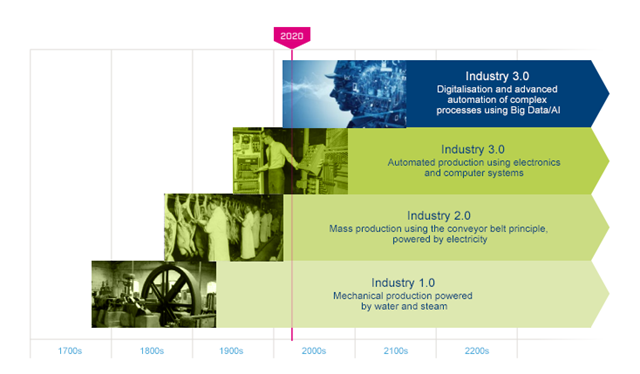

Computers were integrated into Industry 3.0 to reduce the use of manual labour. Industry 4.0 represents the next stage in this process. The focus is now on boosting the levels of communication and automation used in production processes with the aid of massive amounts of data – so-called Big Data.

The aim is to provide consumers with products of higher quality – faster.

“We’re heading towards a future offering zero-defect manufacture – at least in the most modernised manufacturing sectors”, says Project Manager Odd Myklebust at SINTEF.

As the manufacturing sector gradually transitions to Industry 4.0, consumers can expect benefits such as:

- improved product quality due to increased control throughout the entire production process.

- faster delivery due to reduced production times.

- lower prices due to less materials waste and reduced production times.

- the faster development of new technologies.

The EU-funded project ‘Data4.Zero’ involves 20 European partners, including SINTEF, who will be working together to improve the quality produced by European manufacturing facilities. The project is designed to offer companies a digital quality assurance system that will be used to gather and analyse data from manufacturing processes. This will give companies greater control over what takes place during production and will also make it possible to predict and prevent any defects that may occur during the processes.

This is Industry 4.0

Industry 4.0 refers to the growing use of data and computers in industrial contexts. In our modern society, we are already familiar with using computers in our day-to-day work, whether these be our smart phones or self-service checkouts at the supermarket. The fact is that we use data for almost everything – making our lives much simpler. This is also happening in the manufacturing sector. Here, companies are using computers both to design and produce goods, and to monitor entire production processes. The large volumes of data can also be used to optimise and improve these processes.

Watch the video and find out more about the Data4.Zero project.