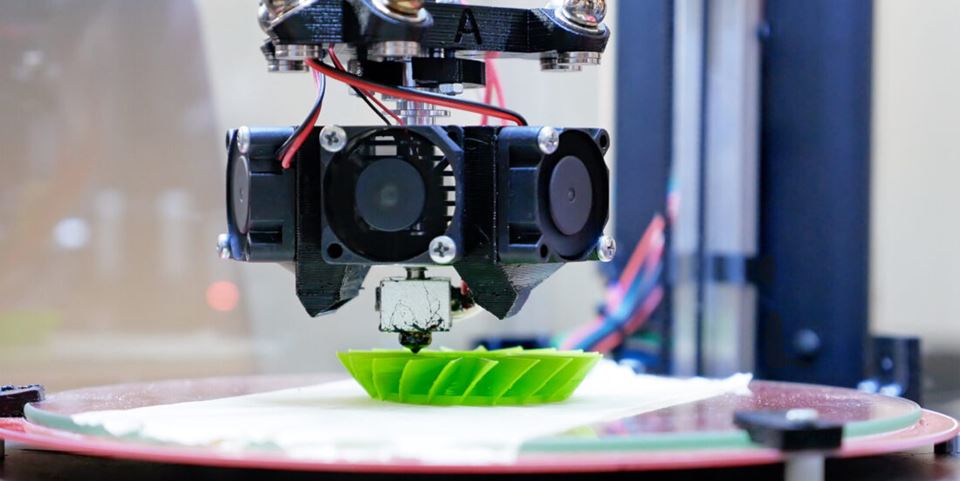

You may have seen, or bought and tested, a hobby 3D printer, which can manufacture an object by melting thin plastic filaments and layering them to form the desired shape. These are fun toys, used to produce small-scale model figures, signs and suchlike.

According to scientists, this technology has now come quite a long way. It is offering us opportunities far in advance of the world of hobby printing, even if the layer-by-layer process is essentially the same.

SINTEF and other major companies, such as Equinor, are using 3D printing technology to manufacture large-scale products, as and when they need them. For example, Equinor has succeeded in printing components weighing as much as three tonnes.

Welcome to the world of digital warehousing

The technical term for large-scale 3D printing is ‘additive manufacturing’, and the technology is offering the sector many new opportunities. This includes the ability to print only the things we really need – precisely when we need them.

“Now that major enterprises such as Equinor are all of a sudden demanding such technologies, we’re seeing the establishment of 3D printing stations that even smaller organisations such as SINTEF can use”, says SINTEF CEO Alexandra Bech Gjørv in the podcast Smart forklart (Smart technology explained). “If something breaks down in one of our labs, or if we need a new component, instead of ordering it from some remote supplier, our first thought now is “can we get it printed at our station in Stjørdal?”, she says.

SINTEF researcher Klas Boivie is one of the guests in this episode of Smart Forklart (Smart technology explained). We see him here telling us all he knows about 3D printing.

In the podcast, Bech-Gjørv goes on to explain that since transport is the source of a large share of SINTEF’s greenhouse gas emissions, having access to a quick and local production facility can make our manufacturing processes, as well as those of other industries, both more efficient and climate-friendly.

3D printing enables us to dispense with large warehouses containing components sitting there just waiting to be used. Instead, we have the opportunity to tailor each new product to the purpose for which we need it.

Simplifying work and reducing warehousing

In the podcast, SINTEF researcher Klas Boivie uses the manufacture of hearing aids as an example, pointing out that 3D printing has now simplified what was previously a very complex task.

“Today, patients can simply have a cast of their ear scanned. The resulting earmould can then be 3D printed instead of sending the job to a technician.

Boivie also tells us that not everything can be usefully 3D printed, but that most products function very well without any major problems. Current technologies enable everything from shoes to buildings, as well as organic materials, to be 3D printed with a greater degree of freedom than ever before without compromising on product quality.

“At Equinor, our focus is on how we can reduce our physical warehousing”, says Executive Vice-President Hege Skryseth. “Our ambition is to halve our capacity and replace it with digital warehousing”, she says. Skryseth is optimistic that 3D printing will make the company more climate-friendly and time-effective in the future.

Listen and learn more about 3D printing in Episode 71 of the podcast Smart forklart (Smart technology explained). 3D-printing: En revolusjonerende produksjonsmetode (3D printing: a revolutionary manufacturing method/in Norwegian).