“We can break seaweeds down into their basic constituents and recombine them to make useful products”, says researcher Silje Forbord at SINTEF. “We can use seaweeds to make clothes, furniture materials, food packaging, drinking straws and biodegradable bottles”, she says.

Forbord and her colleagues have been active in the forefront of a research project called MACROSEA, which is providing new insights into the potential of seaweed farming in Norway. The project has also succeeded in developing innovative solutions that will assist in industrialising the Norwegian seaweed sector.

Silje Forford in the lab at SINTEF, Norway. Photo: Christina Benjaminsen

Seaweed as food

Farming in the productive regions of the oceans is essential if we are to meet the food, animal feed, raw materials and energy demands of an ever-increasing global population. Currently, the greatest volumes of macroalgae are produced in Asian countries such as China, Indonesia, Japan and Korea. However, Norway is catching up fast, and has a massive potential to cultivate a wide variety of macroalgal species along its elongated coastline.

The research group has carried out systematic studies of cultivation conditions, fouling, and the genetics of the brown alga sugar kelp and, for the first time in Norway, has succeeded in growing the much-coveted red alga Palmaria (also known as red dulse) in nets at sea. They have also developed algal growth models, which in turn are linked to 3D hydrodynamic-ecosystem models, in order to estimate how seaweed production progresses under different conditions. The results demonstrate that seaweed farming has the potential to become a major new industry here in Norway.

“We have developed three equipment prototypes for seaweed cultivation, a production potential model, and a computational tool for the design of a marine seaweed farming facility”, says Aleksander Handå, who is a Research Manager at SINTEF Ocean AS.

Facts about the MACROSEA project

The project is funded by the Research Council of Norway and coordinated by SINTEF Ocean in partnership with NTNU, Akvaplan-Niva, NIVA and the universities of Bergen, Oslo and Tromsø. International research partners are Clarkson University, Aarhus University, SAMS and IOCAS, while Austevoll Seaweed Farm, Biokraft, Folla Alger, Hortimare, Ocean Forest, PE Reefs, Seaweed and Seaweed Energy Solutions are participating as associate industry partners. The project has been working from a budget of NOK 25 million, allocated over three years from 2016 to 2019. For more information, visit www.macrosea.no

Solid knowledge base

Silje Forbord is a Research Scientist at SINTEF Ocean and a Ph.D. student at NTNU. She tells Gemini that her group has been looking into how it might be possible to manipulate macroalgae growth and the content of chemical constituents such as proteins by cultivating seaweeds in a variety of locations with contrasting environmental conditions. They have grown seaweed seedlings (embryonic plants) planted in the sea on ropes along the Norwegian coast, and have then observed how these develop over a growing season extending from February to September.

They have studied growth in seaweed exposed to harsh weather conditions and in protected sites, under the influence of fresh water in fjords, and at different latitudes. They have also looked into how variations in light, temperature, nutrient availability and depth of cultivation influence growth rates.

“We have also conducted tests using a variety of seeding methods at sea and have observed how different ages and development phases of the juvenile plants are influenced in terms of development rates and chemical content”, says Forbord.

The researchers have measured oceanic drag forces and have used these data as input to numerical models that can simulate how seaweed farm facilities might be deformed under different environmental conditions. The results are now being used to design seaweed farms for deployment in offshore sites in the county of Møre og Romsdal, and for the production of salmon and seaweeds in a combined aquaculture facility in Nordland.

Substitute for soya and oil-based products

“Large stretches of the Norwegian coast offer excellent growing conditions for seaweed”, says Forbord. “From 20 million tons of seaweed we can extract 100,000 tons of protein. This corresponds to a third of the mass of soya protein that Norway currently imports annually for salmon feed”, she says.

The MACROSEA project is funded by the Research Council of Norway and is a joint effort involving several Norwegian and international research partners. The researchers are unanimous in their view that seaweeds may offer many of the same applications as soya and oil. They may thus be able to substitute for these resources in a number of different contexts.

“The idea of replacing oil-based plastic with an eco-friendly, seaweed-based plastic is very interesting. However, other coveted constituents of macroalgae such as antioxidants, proteins and suchlike are also interesting”, says Forbord.

She believes that, in addition to the manufacture of clothing, food packaging, biodegradable bottles and other products made from seaweeds, more work has to be done on the development of other climate-friendly, seaweed-based products, as substitutes for those currently based on raw materials such as oil and soya. In order to maximise the environmental potential of seaweed cultivation, a new and standardised technology must be developed. There is also a need to upscale cultivation in the form of major industrial-scale farm facilities that be located further out to sea.

Learning from the salmon farming boom

The researchers are making comparisons between current seaweed farming approaches and the way in which salmon farming was carried out in the 1970s. In recent decades, the salmon farming sector has experienced a revolution in terms of standardisation and industrialisation, and this makes it possible to extract a great deal of know-how from fish farming and other marine and maritime industries.

For example, the researchers believe that it is well worth testing a tool used for sowing embryo plants in connection with seaweed cultivation.

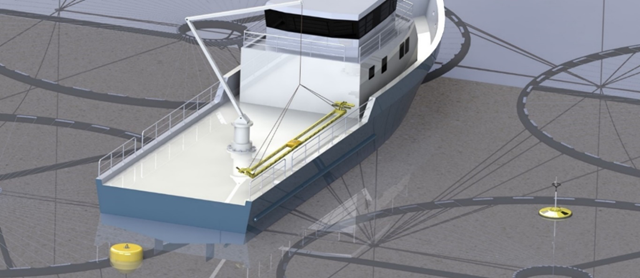

Technology from salmon farming: The Spoke tool uses established technology in an innovative way. The seaweed is grown on spokes fitted to the large wheels. These can be deployed and removed by a robot operated from a service vessel. Illustration: SINTEF

“The tool, called Spoke, looks very like a large bicycle wheel, where we use all the spokes for growing the seaweed”, says Handå. “The spokes can be deployed at sea and removed again using a robot operated from a service vessel. This concept utilises technology taken from the salmon farming sector and enables full-scale automated sowing and harvesting operations”, he says.

The researchers now want to have the opportunity to test Spoke and another technology, both at small and large scales, and under different environmental conditions along the Norwegian coast. They believe that a Norwegian infrastructure for seaweed farming will accelerate digitalisation, standardisation and the automation of on-and offshore seaweed farming facilities.

“We believe that this may be a sound investment to help drive the development of a new industrial sector”, says Handå.

Capturing greenhouse gas

Handå tells Gemini that seaweeds also have the potential to contribute to capture of the greenhouse gas CO2. Photosynthesis enables seaweeds to convert CO2 into carbohydrates and oxygen. The CO2 concentration in the upper part of the water column is in balance with that in the atmosphere. By binding the CO2 in the water, it becomes possible to capture the greenhouse gas from the atmosphere.

If the macroalgal raw materials are used in products whose manufacture is currently based on materials derived from fossil fuels, this will also reduce CO2 emissions. Throughout the growing season, parts of the seaweed blades will flake off as part of a natural process. The blades contain carbon and sink to sea floor where they may provide food for benthic organisms. They also combine with the bottom sediments and are thus stored either permanently or for a prolonged period.

By dumping the biomass at great depths, or by using it to make biocoal, it is possible to make an active contribution towards reducing the concentration of CO2 in the atmosphere. The cultivation of 20 million tonnes of seaweed can bind about four million tonnes of CO2.

“The industrial scale production of macroalgae may prove to be a major contributor to innovative and climate-friendly solutions, a green transition and the movement towards a low-emissions society, thus helping us to meet the targets set by the Paris Agreement”, says Handå.

Paving the way for a new nothern industry

The annual global production of macroalgae has now exceeded 30 million tons, and is mainly based on manual labour. To date, automation is very little used in the production process. The results of the MACROSEA project indicate that the fjords and coastline of Norway have the potential to produce about 70 tons of macroalgae per hectare, and as much as 140 tons per hectare in favourable areas. Researchers believe that in Mid-Norway alone it will be possible to cultivate of the order of 20 million tons (fresh weight) of seaweeds, which in turn results in 2 million tons of dried raw materials. In order to achieve this, 4,000 square kilometres of sea area will be required for cultivation. In comparison, about 1.3 million tons of cereals are currently grown in Norway across an area of 2,800 square kilometres.

“If a policy is developed to cultivate seaweeds offshore, away from the coastline, the potential may be even greater”, says Ole Jacob Broch, a Senior Research Scientist at SINTEF Ocean. He continues: “We saw that the period of maximum production yield varies by up to two months as we progress from south to north along the Norwegian coast”, he says. “This is good news because it shows that it is possible to deliver raw materials produced in Norway over a longer period. This makes our coastline ideal for the farming of macroalgae”, says Broch.

Great expectations are now being linked to the emergence of seaweed farming as a new Norwegian industry.

“Nationwide investment in an infrastructure for the development and standardisation of new technology for industrial biomass production is a prerequisite for success”, says Handå.

Researchers believe that by integrating knowledge centres with industrial companies along the entire length of the Norwegian coast will promote the establishment of world-leading innovation clusters and accelerate relevant research both in Norway and around the world.

“Currently, it is mainly only the cultivation of seaweeds for food that is profitable. However, the development of new technologies for large-scale biomass production may change this”, says Handå. “In the coming decades, the world will be demanding more animal feed and large volumes of renewable raw materials. The industrial production of seaweed may then become part of the solution. Norway’s elongated coastline, combined with an investment in research into seaweed farming, will form a solid foundation for Norway’s ability to succeed in developing seaweed farming as a commercial industry”, he says.