With every passing day, the need to change society to cope with climate change becomes ever more urgent.

At NTNU’s Department of Energy and Process Engineering, engineers have been working to modernize Norway and develop new technologies for society for 110 years. Over the years, these engineers have often taken existing technology as a starting point to create something new.

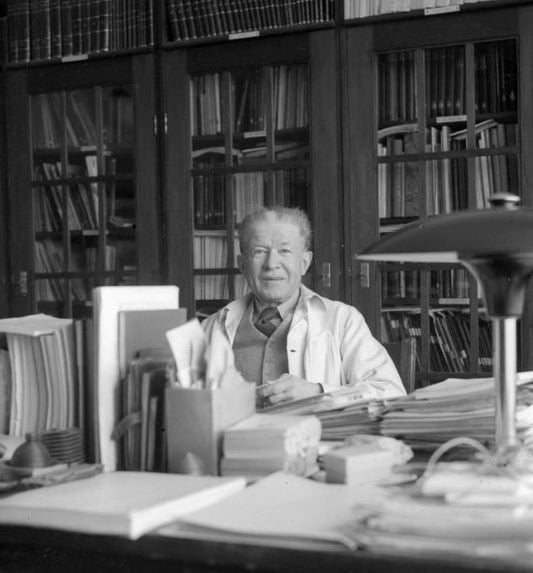

Terje Finstad is one of three authors who wrote the book on the history of science at the Department of Energy and Process Engineering. Photo: Idun Haugan / NTNU

Now the story of the academic community’s role in the development of Norwegian society has been compiled and presented in a new book. Terje Finstad is one of the three authors of the book about the department’s history.

About the book and its authors

- The book Fra varmekraft til bærekraft. Historien om energi- og prosessteknikk ved NTNU 1910-2020 (From thermal power to sustainability. The history of energy and process engineering at NTNU 1910-2020; in Norwegian only) was written by Per Østby, Terje Finstad and Håkon B. Stokland.

- The book was published by Museumsforlaget in September 2020.

- The book deals with the history of the Department of Energy and Process Engineering at NTNU – from the education of engineers who took part in the industrial modernization of Norway in the early 20th century to contemporary engineers working for global and environmentally oriented modernization projects.

- Per Østby is a professor of the history of science and technology in NTNU’s Department of Interdisciplinary Studies of Culture.

- Terje Finstad is a researcher in technology and science studies in the same department. In addition, Finstad has an adjunct position in the Department of Archaeology, History, Cultural Studies and Religion at UiB.

- Håkon B. Stokland is a researcher at the Norwegian Institute for Nature Research (NINA) and also holds a part-time position as a researcher in NTNU’s Department of Interdisciplinary Cultural Studies and Religion at NTNU.

“This field has a broad and interesting history. The innovation doesn’t come from one ingenious person with a completely new idea, but often from people and academic groups who’ve taken hold of existing technology and tested, adapted and improved it – and thus created new technological opportunities. I find that fascinating,” says Finstad, a researcher and science historian.

Created energy for the country

NTNU’s Department of Energy and Process Engineering tackles a wide range of energy research: engineers here have developed hydropower technologies that have given Norway a huge advantage in its energy supply.

In partnership with SINTEF, they developed freezing techniques that have built huge economic growth in the fishing industry. They improved the indoor climate in post-war housing construction, worked out solutions in many fields for energy production and energy consumption, and contributed to developing the oil and gas industry. And this is only a partial list.

The same research environment contributed combustion expertise to the Olympic torch in 1994 and ran wind tunnel experiments for everything from national alpine teams to top cyclists.

And in recent decades, climate-friendly energy solutions have come to the fore. We’ll come back to that later.

- You might also like: One hundred years of producing energy — from water

“Farthest college outpost to the north”

Adolf Josef Wilhelm Watzinger (1879-1959) was employed at NTH as a professor of mechanical engineering. He was NTH’s very first professor. Photo: Unknown (original available in NTNU’s special collections)

The story began with Adolf Wilhelm Josef Watzinger, who arrived in Trondheim in 1910. He had a degree in civil engineering from Darmstadt University of Applied Sciences in Germany and became a key figure in the development of NTH and the academic setting described in the Norwegian book Fra bærekraft til varmekraft. Historien om energi- og prosessteknikk ved NTNU (From sustainability to thermal power. The history of energy and process technology at NTNU).

Trondheim now became the base for Norway’s first higher technical education programme, “the farthest college outpost to the north,” as Rector Sem Sæland said in his speech at the opening of NTH in 1910.

The new college marked something new, not only in Trondheim’s history but also in the history of Norway. The Norwegian modernization project had its roots in the early 19th century and started as a cultural project to form a free and modern society.

The project eventually came to include technological and industrial contributions. The term technical modernization refers to how technology and technical expertise were mobilized to liberate people from poverty and to build the country.

On one level, the book is about a group that was given this role, and how the mobilization was manifested.

The three phases

The development in the stronghold of the engineers’ academic setting is divided into three phases, which naturally coincide with societal developments.

Phase one lasts from the beginnings in 1910 to 1940: “Engineers for industry.”

“In this phase, the engineers and professors focus on testing things and technologies on behalf of industry. The professors are thus included in the industrial modernization project,” says Finstad.

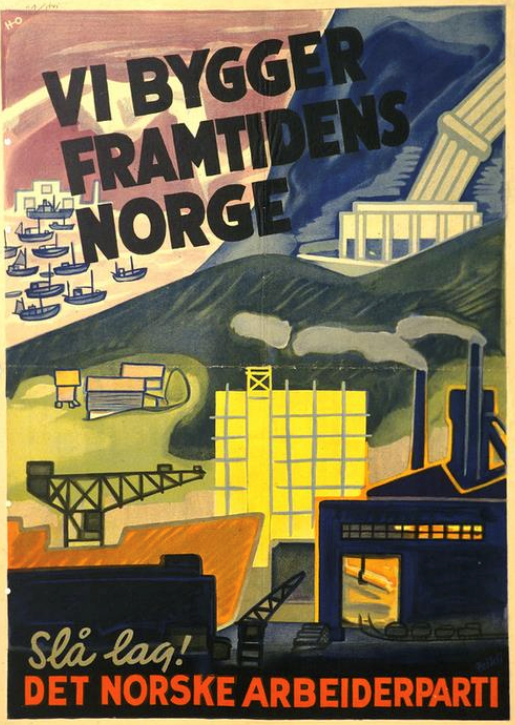

Illustration: Election campaign poster designed for the Norwegian Labour Party for the 1945 Parliamentary election by Dagfin Peikli / Arbeiderbevegelsens arkiv (Labour Party archives) and library (Arbark).

Phase two runs from 1945 to the early 1980s: “Engineers for community building.”

“During this period, engineers become part of major technology projects and of community building. Authorities and politicians establish more assignments and initiatives,” says Finstad. During Norway’s reconstruction and modernization of society, the authorities put major projects on the agenda.

Phase three runs from the early 1980s until today: “Engineers for a global environmental perspective.”

“New societal expectations arise in this phase. They come from people and from industry, demanding a response to global challenges, especially those related to climate. Much of the research in the department now focuses on climate-friendly energy solutions. The department work is also becoming more research-oriented, and international collaborative projects bring a more global focus,” Finstad says.

The phases are not clearly separated, but shifts in emphasis are apparent.

“The industrialization project was expanded to include a community building aspect and eventually an environmental aspect. In other words, the project is not a linear history, but one where aspects are layered on top of each other,” says Finstad.

Watzinger the pioneer – and the freezing technique

Freezing technology is an important field in the department’s history, and Watzinger was a pioneer and driving force in this area. The freezing technique was initially linked to fish, which was and is one of Norway’s most important natural resources and export industries.

As early as the 1920s, another pioneer had invented a method for transporting and exporting fish. Nicolai Dahl in Trondheim had figured out that by putting fish in brine together with ice, the fish could be exported by ship all the way to the USA. This technique enabled Norway to reach a new large market.

In the 1930s, the Watzinger research group became interested in testing various solutions for freezing fish, including those invented by Dahl and other innovators, as well as mechanical freezing methods.

Copied and shrank German freezers

The Indus fish freezing factory in Hammerfest. Photo: Museums for coastal culture and reconstruction in Finnmark IKS

During the German occupation from 1940 to 1945, the Germans naturally also became aware of the value that lay in the fishing industry. They built the first mechanical freezers in Hammerfest, Melbu, Trondheim and Ålesund to be able to store and then export fish.

When Norway started to rebuild after the war, these freezers were deemed too large and inappropriate for Norwegian conditions. The Ministry of Fisheries wanted freezers that were better suited to the Norwegian fishing industry.

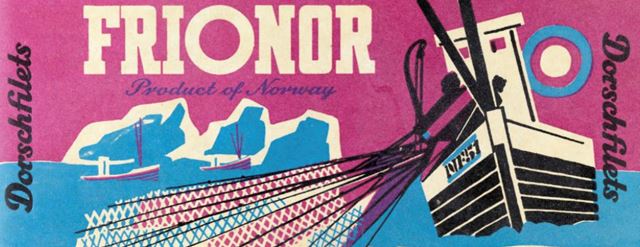

Then the NTH engineers once again did what they were good at: They took existing technology as their starting point, and adapted and reduced the freezer size. This jumpstarted a large frozen fish industry.

Photo: Norwegian Technical Museum

After 1945, the authorities took on a greater role in providing jobs and commissioning research and new technological development.

Gustav Lorentzen – student and successor

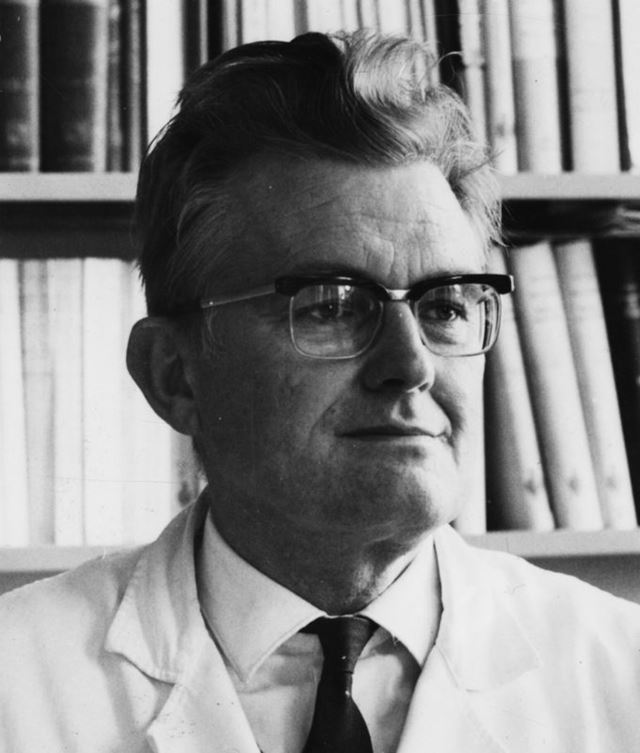

One of Watzinger’s students was given an important role in refrigeration technology. This was Gustav Lorentzen, a collaborator and eventual successor to Watzinger. He gradually became an international figure in refrigeration technology research, with Norway taking a leading role in the 1980s.

“Refrigeration technology was one of the department’s first internationally recognized research environments. In the book, we refer to the engineers of this period as ‘transition agents’; that is, professionals who were contributing to change,” says Finstad.

Gustav Fredrik Lorentzen, professor of refrigeration technology at NTH. Photo: Unknown (original available in NTNU’s special collections)

The use of CO2 in cooling processes became one of Professor Lorentzen’s specialty fields.

He hit upon this path when he worked as a sailor for a short period before he became an academic and researcher. Here he became acquainted with CO2 as a refrigerant used in shipping.

“The Lorentzen group began testing CO2 as a refrigerant, first in refrigeration systems for the automotive industry, then for refrigerated counters in shops,” says Finstad.

In Norway, almost 100 per cent of new systems use CO2 in their refrigerated and freezer supermarket counters. India has also adopted this cooling technique, where CO2 replaces environmentally harmful, synthetic gases such as hydrofluorocarbons (HFCs). In practice, the CO2 in refrigeration systems does not contribute additional CO2 emissions because the CO2 comes from surplus gas from other industrial processes that would otherwise have released the gas directly into the atmosphere.

About the Department of Energy and Process Engineering

- The Department of Energy and Process Engineering is today one of the largest departments at NTNU.

- What started with two laboratories (Varmekraftlaboratoriet in 1912 and Hannkraftlaboratoriet in 1917) and the profiled professors Adolf Wilhelm Josef Watzinger and Gudmund Sundby, by 1985 had become eight departments with great academic breadth and weight.

- Disciplines as varied as aerodynamics, water turbine development, freezing and cooling technologies, control of indoor air conditioning, compressor technology and industrial ecology gradually came together in new project-oriented groupings, and in 2003 were combined into the Department of Energy and Process Engineering (EPT).

- The department is currently involved in several FMEs (Centres for Environment-friendly Energy Research), and in addition to hosting FME HydroCen, the academic community is involved in FME Bio4Fuels, HighEFF, and NCCS.

- The department is also involved in research-driven innovation (SFI) centres in metal production and the maritime sector.

Today, NTNU and SINTEF are collaborating on a number of refrigeration research projects, including in the FME HighEFF research centre, with a number of other partners.

- You can read more about this: Green cooling with CO2

Climate and environment kick in

The third period in the department’s history begins in the 1980s.

“During this period, the environment and sustainability are strongly integrated into the engineering disciplines. Society starts to recognize the consequences of the modernization and industrialization that have taken place, often at the expense of nature. Criticism of hydropower development is growing and becoming evident,” says Finstad.

In the battle over hydropower development, the Alta controversy in 1980 evoked the most significant protests. Photo: Unknown / World Heritage Rock Art Centre – Alta Museum

Until this time, the focus had been on repairing the harmful effects that industrialization had on nature.

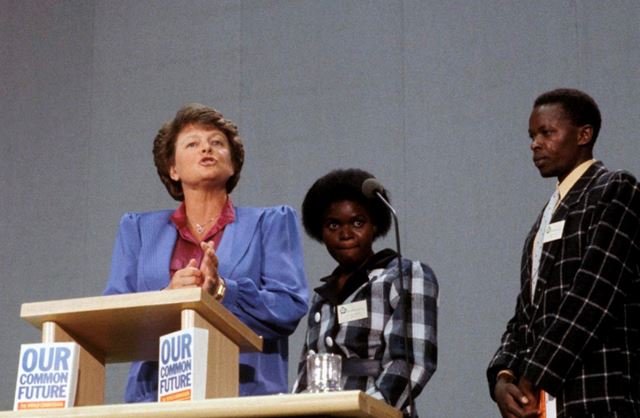

Gro Harlem Brundtland presents the report from the UN’s World Commission on Environment and Development: Our Common Future in 1987. The Brundtland report focused on global sustainability. Photo: Henrik Laurvik / NTB Scanpix

In the 1980s, the thinking and attitudes towards environmental issues begins to change. The waking environmental awareness of the 1970s, especially among young people, is gradually taking hold in many parts of society.

“Now the focus shifts to assessing climate costs in advance, instead of repairing them after the fact. The industry is beginning to think about restructuring and takes action to meet new requirements and expectations. And research communities have to adapt to respond to demands from industry and society,” says Finstad.

Generational shift

One person who understands that a change is needed is Rolf Marstrander. He is the director of HSE and technology development at Norsk Hydro and sits on the NTH board. He had seen the emergence of the field of industrial ecology at the renowned Massachusetts Institute of Technology (MIT) in the USA. Marstrander and Helge Brattebø, who is the current director of NTNU Sustainability, become a driving force for NTH to introduce this field and study programme.

NTH becomes one of the first educational institutions in Europe to introduce the Industrial Ecology study programme in the latter half of the 1990s.

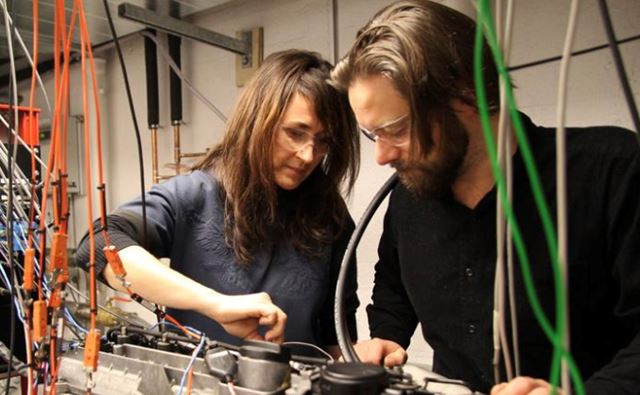

The picture is from when Professor Terese Løvås led the Motor Laboratory. Here with David Emberson. Løvås currently heads the Department of Energy and Process Engineering. Photo: NTNU / Per Henning

Interdisciplinarity gains ground in the engineering disciplines during this period.

“The complex issues facing society cannot be solved by a single area of expertise; interdisciplinary expertise is needed. Young engineers drive this movement forward and are part of the generational shift of the times,” says Finstad.

“The focus on internationalization and international research collaboration is on the rise, and today the Department of Energy and Process Engineering has several internationally outstanding research environments,” Finstad says.

This article describes some of the many disciplines at the Department of Energy and Process Engineering. The book covers the full breadth of the department’s long and rich history, both in text and pictures.