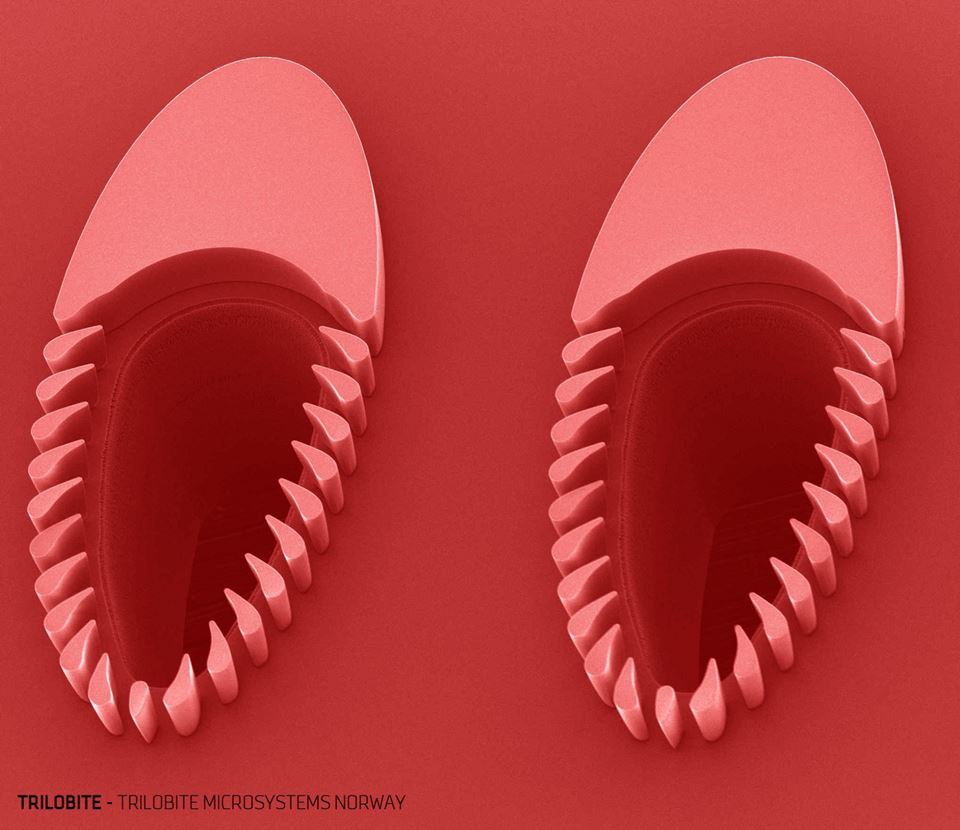

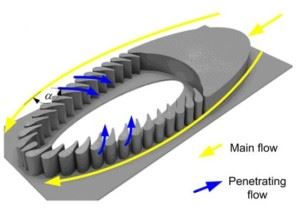

The separation process is facilitated by applying the principles of hydrodynamics. Water, blood and other types of fluid flow around the elliptically-shaped trilobite which is equipped with minute openings that filter and separate out any solid particles.

The company Trilobite Microsystems is currently working on a series of pilot projects using filters that can separate out particles as small as two micrometres and larger. The silicon structures in the trilobite filters are being made by researchers at MiNaLab at SINTEF.

FACTS:

Trilobite Microsystems AS has 7 employees in Kristiansand and an office in Vestfold. The company was founded in 2011 by Eirik Bentzen Egeland.

His collaboration with research scientists started in 2013 with support from the Norwegian micro- and nanofabrication facility NorFab, which is funded by the Research Council of Norway. NorFab represents an association of several Norwegian clean room laboratories including those at the University of Oslo, SINTEF, NTNU and the University College of South-East Norway.

The small start-up company Trilobite Microsystems applied for, and succeeded in obtaining, funding, which has in turn lowered the threshold for its achieving a collaborative project with SINTEF.

SINTEF MiNaLab carries out research and development in the field of microsystems and nanotechnology.

A platform technology with benefits

Eirik Bentzen Egeland is an inventor and entrepreneur, and founded the company in 2011 on the basis of his Masters’ degree from the University College of South-East Norway. He says that the advantages of the new device are two-fold. It requires very little energy to pump a fluid through the structure, and it doesn’t become blocked as other filters do. Moreover, the technology is very flexible and scalable.

“Our filter system is a platform technology with multiple applications”, says Egeland. The structure in the device has to be specially adapted both to the type of fluid requiring filtering and its volume. In the case of blood it is an advantage when making diagnoses to separate out the different components and to remove “noise”. For example, white blood cells are 5µm (micrometres) across. So if you want to filter out particles, viruses and bacteria, you need to reduce the gaps between the micro-pillars to dimensions approaching 1µm. This is why it is a major advantage that the technology is scalable since this enables the filters to separate out particles from fluids over the entire range from 1 to 100µm.

Trilobites were a group of segmented animals that lived from the Cambrian period (about 550 million years ago) until they died out at the end of the Permian.

Egeland says that the company currently has a pilot plant installed in Kristiansand. “We’re treating large volumes of water used in a commercial vehicle washing facility. We remove all particles greater than 50 µm in size, enabling us to recirculate the water”, he says.

Pushing the boundaries

At MiNaLab in Gaustadbekkdalen, SINTEF researchers are working on a technology they call ‘nanostructuring’.

The figure illustrates how the water flows around and through the trilobite. Solid particles are filtered out as water passes through the gaps between the micro-pillars.

“We etch out the pattern of the trilobite on a silicon wafer”, says Michal Mielnik. “We’re really pushing the boundaries here when it comes to manufacturing a structure in which the openings between the pillars must be very small and at the same time installed in channels that are several millimetres wide”, he says.

Both SINTEF and Trilobite Microsystems are benefiting from their participation in the NBRIX project, which is looking to micro-components designed to address problems linked to interior environments, transport and health issues. The project is funded by the Research Council of Norway.

The researchers are using silicon wafers as the basis for component manufacture and applying technologies derived from micro-electronics. However, instead of making conductors and transistors, they are etching out microscopic channels and pillars with nanometre precision.

Mielnik believes that later this winter they will succeed in producing structures that can filter out particles as small as 2 µm and greater. “This presents us with two challenges”, says Mielnik. “Firstly, can we achieve the geometries that Trilobite Microsystems is looking for? And, if so, will these geometries do the job the company wants? We’ll only find answers to the second question after the company has tested the devices to see how they work”, he says.

Ambitious targets

Eirik Egeland is setting ambitious targets. He is currently working as fast as he can to commercialise the technology, and is planning to use a new version of the device to filter ballast water from ships that is normally flushed into the sea. However, the ultimate, long-term aim is to decontaminate drinking water.

The ultimate, long-term aim is to decontaminate drinking water. Photo: Trilobite Microsystems AS

“Our technology is unique because it will require less maintenance and will thus be less expensive when it comes to decontaminating drinking water. The resulting water will be pure and entirely safe to drink”, he says. “But that is some way down the line. Currently we’re looking at industrial waste water”, says Egeland.