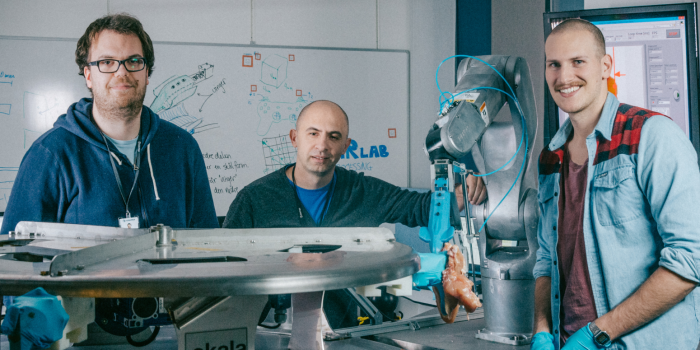

They have built a fully-functional robot in the lab to automate the process of extracting breast fillets from chickens. This is a task normally performed by skilled human hands.

“Our aim is to automate absolutely everything we can think of on the food production line”, says Ekrem Misimi at SINTEF.

This will make Norwegian food production more sustainable, both in terms of profitability and utilisation of raw materials.

Sharp-eyed robot with nimble fingers

Ekrem is a technical cyberneticist with a doctoral degree in machine vision, and has specialised in providing robots with sharp, three-dimensional vision – which in this case means eyes for the anatomy of a chicken.

“Automating this process is something that no one else in the world has succeeded in doing before. Except us”, says Misimi proudly.

“We at SINTEF are the only specialists in Norway to have focused on solving these kinds of problems for the food industry”, he adds.

How GRIBBOT learns to grasp chicken fillets with precision

- A transport system secures the carcass and brings the chicken to the robot and within the range of its 3D machine vision system.

- The robotic arm is equipped with a grasping tool. The tool is made up of two plates, the topmost of which is pointed and flexible, which allows it to scrape the chicken fillet away from the carcass. The 3D vision (via the camera and algorithms) recognises/determines exactly where the robot should grasp the fillet.

- When the carcass is scanned, a specially designed computer program identifies the point at which it should be grasped. The program converts the position of this point into a robotic movement that removes the fillet. In the same sequence, any remaining chicken fillet is scraped away from the carcass, thereby utilising all the meat.

So far, one of our results is the robot Gribbot, named because of its resemblance to a vulture’s beak (‘gribb’ is the Norwegian for vulture).

Gribbot is well equipped. It has a hand for grasping, specially developed ‘fingers’, and three-dimensional vision. Its ‘eyes’ have been borrowed from a 3D camera familiar to all games fans – the Microsoft Kinect 2.

These are all needed because a chicken fillet is a delicate object that must be handled extremely carefully. The robotic hand must not spoil it with marks or other quality defects. Both the robot’s vision and its grasping hand are critical factors.

Smooth and shiny

“Generally speaking, it’s a major challenge to get a robot to process biological raw materials, because it involves automating a task that is normally performed by skilled people. The raw materials also vary in terms of their size and properties. It’s easy to deform or damage a chicken fillet”, explains Misimi.

And because it’s so smooth, a chicken fillet is also an extremely reflective object. That makes it difficult to obtain fully detailed 3D images. The texture also means that the meat is hard to grip.

“We realised this early on when we began our research, and were determined to develop a flexible system that could not only tackle variations in the raw materials, but also the mechanical challenges of extracting the fillet from the chicken”, says Misimi.

Mathematical ‘brain surgery’

Naturally, controlling the robot is a key factor. The algorithm, or mathematical computational model, that constitutes the brain of the robot has also been developed by SINTEF. It is this that enables the robot to perform the operation to the same standard as a human being.

FACTS:

The project CYCLE will see the industry and researchers working together to utilise food that currently fails to reach the shops. Every stage from production to processing will be optimised, and every resource exploited to the full.

The project, which has a four-year budget of NOK 50 million, was launched in 2013 and is headed by SINTEF Fisheries and Aquaculture.

In 2011, an estimated 816,000 tonnes of waste raw materials were generated by the seafood industry, while slaughter waste from the meat and poultry industries amounted to 220,000 tonnes. These figures underline how important this project will be from a financial, environmental and societal perspective. The researchers will now get down to work employing tools such as sensor technologies, robotisation and increasingly environmentally-friendly processes with the aim of utilising waste not only from food production, but also from food which consumers currently throw away.

The CYCLE project has broad political support. According to the Norwegian Ministry of Agriculture and Food, reducing food waste should be one of the most urgent environmental issues both in Norway and the rest of the world. The 'cyclical' approach, involving the optimal and environmentally sound exploitation of biological raw materials, combined with a focus on wealth generation, is an issue high on domestic and global agendas.

To read more about the project and interviews with some of the partners involved, visit the project website at www.cycleweb.no

If the robot’s arm is to be guided precisely to the raw materials with the aid of 3D images, it is essential for the camera (the robot’s eyes) and the robot itself to ‘speak the same language’.

“In other words, the robot’s coordinate system must be able to understand the coordinates identified by the machine vision”, explains Misimi.

In order to address this problem, the robot is pre-calibrated to ensure that its ‘hand’ and ‘eye’ understand each other.

To the last shred

Gribbot has been developed as part of a larger project called CYCLE. Its main aim is to make Norwegian food production, including fish, vegetables and meat, more profitable, more environmentally friendly and more efficient. In other words – more sustainable.

“The fact is that almost half the food currently produced never reaches the consumer because it is lost along the production line due to the fact that we don’t have the technology to process the raw materials”, says Misimi.

More profitable and environmentally-friendly

“Automating this work will speed up production and make it more efficient. It will free up the producer’s capacity and make better use of the raw materials. In the case of chicken fillets, this also means making optimum use of the material. A flexible grasping tool scrapes the carcass while it is pulling off the fillet, and this removes as much of the meat as possible”, explains Misimi.

The idea is to continue developing Gribbot as part of future projects, so that it will be possible to make use of any meat that may be left on the chicken carcass after the fillet has been ‘harvested’ by the robot.