Scientists at SINTEF in Trondheim have set out on an unusual journey – into the interior of certain materials. They are about to build a mathematical model of tiny but vital zones in aluminium vehicle bumper systems. The research group will use this virtual “mini-laboratory” to study the chaos we create when we crash a car.

The model will be the first in the world that enables us to perform calculations on these phenomena in aluminium components.

Senior consultant Trond Furu in Hydro was involved in commissioning the project, and he has great expectations regarding the model on our behalf too:

“The model will give us new knowledge of how the composition of their component materials affects the properties of aluminium alloys. By linking this knowledge to the expertise of the designers of vehicle components, we can create alloys that will make vehicles safer,” says Furu.

What takes place at atomic level in a vehicle’s crash-box when we collide? Inga Gudem Ringdalen and her colleagues are providing new knowledge of this topic in order to make cars safer. Photo: SINTEF/Svein Tønseth

Click to open

Soft “zip fasteners”

The project’s focus on aluminium has not come about by accident. Car manufacturers are using aluminium more and more for bumpers in order to reduce the weight of their vehicles, and thus their emissions.

The bumper system lies behind the plastic fascia that most of us call the “bumper”. Behind this lie the bumper beams, and behind these a “crash box” that absorbs energy from the impact.

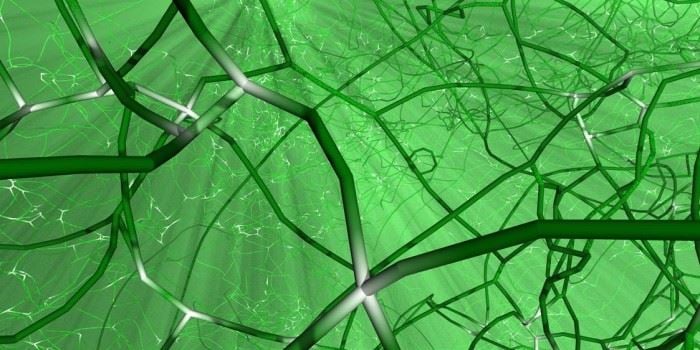

In these aluminium boxes the metal has a granular structure. Each grain is made up of atoms stacked in a highly ordered 3D lattice, all of them with the same spatial orientation.

The grains themselves are extremely strong, but between them are thinner zones that can act something like a zip fastener. It is these that SINTEF is going to examine in detail, because no-one knows how these “zips” behave when we crash.

“Good” disorder

Research scientist and project manager Inga Gudem Ringdalen explains that aluminium atoms are stacked like oranges in a greengrocer’s window.

“When you crash, the layers in the stack are displaced, and the disordered state that results differs from one alloy to another. And the faster and further that these irregularities are able to propagate in a collision, the greater are your chances of emerging unscathed from the car. However, until now it has never been possible to calculate phenomena of this sort.

How the mathematical model will be developed

- A mathematical model describes reality with the help of equations.

- Important inputs to the model being developed by SINTEF are taken from other models that show how atoms affect their neighbours when aluminium alloys are exposed to extreme loads.

- In order to identify the rules by which layers of atoms react, SINTEF will use a computer program developed by materials scientists at the Lawrence Livermore National Laboratory in the USA.

- The aim of the American program was to describe similar phenomena in other materials. SINTEF will adapt it for use on aluminium alloys.

“In a crash, atoms in vehicle components can be pushed out of their “preferred” positions. The scientific term for such changes of position is “dislocations”. If a large number of dislocations occur virtually simultaneously, they can slow each other down, which helps to hold the material together.”

“And the stacks of atoms that stay in position; are they not just as useful for ensuring road safety?”

“If atoms are dislocated without meeting a lot of resistance, the result can be that the material will fracture, and the chances of injury increase if parts of a vehicle’s structure disintegrate in a crash.

“And why is it so important to know just how much the zip-zones can withstand?”

“Because it is when the “zips” in the metal open that materials come apart.”

“The missing link”

Wrecking entire cars and components is an expensive process when a scientist wants to see what happens in a collision, which is why the project team is creating a “virtual laboratory” – because that is what the mathematical model really is.

NTNU and SINTEF have already come a long way with the same thing in full scale in the SFI SIMLab research centre next door. The centre has developed numerical tools that can simulate how an entire car is affected by a collision.

The automotive industry is already using the results from this large virtual laboratory. According to Ringdalen, the models that will be developed here will provide even better estimates when her project has finalised its modelling software.

“This is because the mechanisms that act at atomic level in the zip-zones have been the “missing link” in every crash model that has been developed for aluminium and other metals,” says Inga Gudem Ringdalen.

More than aluminium

- The mathematical model currently under development at SINTEF will be used in the first place to calculate how aluminium deforms.

- It can later be adapted to perform calculations of deformation in other metals.

- Potential areas of application include the development of “Arctic steel” that will be capable of withstanding extreme cold without becoming brittle, and materials for use in gas and CO2 pipelines.