Polar explorer Børge Ousland and research student Sindre Sandbakk have one thing in common: they are quite happy to push their own bodies to the limit in bitter cold.Their willingness to perform in the cold has intriguing scientific ramifications.

Photo: Nucleus Medical Art, Inc.

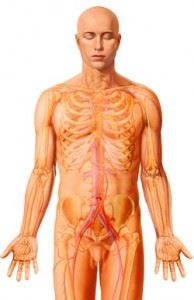

How the body reacts to cold

When we are naked, we are comfortable at a temperature range of 28 – 33o C, while the optimal operating temperature for our internal organs such as the heart, liver and lungs is 37 degrees. Muscles perform best at a slightly higher temperature.

The body generates its own heat – enough to compensate for heat loss to the environment. But as soon as we lie down on the sofa we lower our rate of heat production, and we need extra insulation such as blankets.

Fingers and toes are most vulnerable to heat loss. At eight degrees below zero, fingers become numb and clumsy. It becomes difficult to tie our shoelaces, to zip up or to handle instruments. Below -15 degrees, mobility and fine motor movement gradually disappear. At even lower temperatures, our cognitive ability is also affected.

Heat is lost from the surface, so that the peripheral organs are the first part of the body to cool down. The body protects itself against heat loss by cutting the blood supply to the outermost skin layer and withdrawing blood back into the body, which slows down the rate of heat loss.

The only way to warm up our hands and feet again is to get the body to send warm blood out to them. The best way of doing this is by exercise.

Wearing clothes creates a microclimate close to the body that stays at 28 – 33 degrees. With good insulation, the outer surface of our clothes will be at virtually the same temperature as the ambient temperature, thus helping to delay heat loss from the body.

Click to open

Sindre weighs 70 kilos and is 172 cm tall in his stocking soles. He has an oxygen uptake rate of 78, a resting pulse rate well below 40, and a close, and warm, relationship with his ten pairs of skis, as well as with the NTNUI Cross-country Ski Club. At the moment, he is standing in SINTEF’s Work Physiology Laboratory clad in a closely-fitting thin red cross-country ski-suit from Swix, a black cap and jogging shoes.

This young man is one of several volunteers who have been running in double-figure freezing temperatures until their lactic acid balance causes them to stop, and all for the sake of research. Today, he will once again, of his own free will and for a modest payment, push his own body to the stage known by scientists as “total exhaustion”. For this purpose, he will be fitted with 13 thermistors (tiny temperature sensors), cables, air-hoses, and a computer that will reveal most of the details of his performance and reactions.

However, he is not worried. Today’s run will be a gentle one: the scientists have set the ambient temperature at 15 degrees above zero, because they also need data to compare with Sindre’s performance at 20 below.

“The tests will provide us with general knowledge about how the human body performs in cold; how and when it weakens us,” says test manager Øystein Wiggen of SINTEF Health Research, as he shows us a graph known as the Ramsey Curve.

Cold facts

The test that is about to commence is just one of a series of a hundred. The general aim of the ColdWear project is to gat-her physiological data on how we react to cold. These data will give scientists the expertise they need to develop what they call “advanced protection” for persons who operate in our most severe climate zones, such as Siberia and the Arctic.

Among the products envisaged by the scientists are “intelligent” extreme-weather clothing. Technical clothing for elite athletes are also on the scientists’ list of potential products that could see the light of day as a result of this project.

A total of 21 persons have been tested under six temperature conditions, ranging from + 20 to -25 degrees, in the course of the past six months. The scientists have also carried out tests of “manual capacity”, which gives an idea of what cold does to our ability to concentrate and perform fine motor tasks at different temperatures, a capacity that is extremely relevant to industry.

“It is quite impossible to imagine what it is like to work in these regions, where temperatures can fall to 60 below zero.”

Scientist Hilde Færevik

No other research team anywhere in the world has tested human subjects in extreme cold in this fashion. The figures obtained by the tests will soon be systematized, and the results will become a database of “cold” facts.

“The results so far show that cold has major effects on both fine and coarse motor capacity, which indicates that there is a real need for new clothing concepts,” says Øystein Wiggen.

Extreme reality

While Sandbakk gets ready to enter the treadmill, research scientist and ColdWear project manager Hilde Færevik pops in to make sure that everything is going according to plan.

“It is impossible to imagine what it is like to work in the harshest climate areas, where temperatures can fall to minus 60 degrees. What is clear is that there is a need for advanced protective clothing when you are working under these conditions. And work of this sort is necessary, because technical equipment needs constant maintenance in extreme cold. This is why the tests that we are carrying out just now are an important aspect of the ColdWear project,” says Færevik, as she mentions some of the ideas that her research group in SINTEF is working on:

“We are thinking of clothes made of functional materials which, for example, can store excess body heat that can be extracted from the garments when the temperature falls again. We are also developing clothing with integrated sensors that both monitor the person wearing them and communicate with the outside world,” she says.

Færevik emphasizes that the real world can produce far worse climate conditions than the scientists can simulate in the laboratory, so she hopes that SINTEF’s efforts will be both useful and profitable. One third of the world’s oil reserves are estimated to lie in arctic regions. The oil companies and contractors that will operate in these regions will face enormous challenges in terms of HSE, in addition to technical problems.

For this reason, part of the research project will consist of interviewing people who have lived under extreme weather conditions. Børge Ousland is one such person whom the scientists plan to interview.

“An arctic explorer like Ousland has unique experience that would be very useful for us,” says Færevik.

An hour of hard work

Sandbakk is almost ready. The treadmill has not been set up for a Sunday trip, but for aerobic exercise, and its ventilation fan, which is nearly a metre in diameter, will make sure that he has plenty of air resistance.

“All of the air that passes in and out of Sandbakk’s system will be measured by this, which enables us to measure his oxygen uptake, how hard he is working and how much heat he is gen-erating,” explains test manager Øystein Wiggen.

The country-country skier is sent to the treadmill, where today’s task is to complete four runs of gradually increasing difficulty, before a final trial that will involve “giving everything” – a maximum test to exhaustion. The test manager monitors the graphs on the computer screen closely. No-thing is left to chance; everything must go according to plan. If there is even a suspicion that something is wrong with the athlete, the test will immediately be stopped.

A Hans-Rudolf valve is inserted in Sindre Sandbakk’s mouth; used in conjunction with a nose-clip, this produces a closed breathing system. The test reveals Sindre’s maximum oxygen uptake capacity, and shows where his lactic acid threshold lies.

Photo: Thor Nielsen

Click to open

Now Sandbakk is warming up. Then comes the set of gradually increasing ten-minute “drags”, each followed by a two-minute pause to enable a sample to be taken for lactic acid analysis.

The hunt for the perfect sensor

Meanwhile, five hundred kilometres away in Oslo, SINTEF ICT researcher Trine Seeberg is working on another problem: what is the best way of attaching sensors and electronics to textiles?

“We are thinking that we can integrate sensors into clothing that measure heart-rate, respiration rate, activity level, humidity and temperature, or various combinations of these.”

The scientists believe that the data mea-sured by the sensors could be coupled up to the wearer’s mobile telephone, which in turn can send the information wirelessly to a control room. Sensors of this sort would enable the wearer’s state of health and working conditions to be monitored, which would make it possible to interrupt a task if necessary.

“Monitoring will give us a picture of the level of risk run by people working under extreme conditions, such as in Russia’s Shtokman field,” says Seeberg.

However, developing measurement sensors of this sort is one of the major challenges that face the project: the electronics would have to withstand machine washing, wide swings in temperature and heavy use. Some of the sensors would also need to be attached to the skin. Satisfying requirements of this sort is not done “just like that”.

The scientists will also need to finds ways of supplying the electronics with enough power to enable the clothing to operate wirelessly for long periods.

“Bluetooth technology works fine, but any- one who has ever tried to transmit images from a mobile phone via Bluetooth has certainly found that the mobile loses battery power quickly, so we are working on electronics that are less energy-intensive than current systems,” explains Seeberg.

THIS IS COLDWEAR

An interdisciplinary project aimed at developing clothing for use under extreme conditions. Project duration 2008 – 2012.

Financed by the Research Council of Norway (NOK 13 million) and industry (NOK 4.5 million).

The project employs a total of 8–10 researchers. The oil companies Statoil and Total, and manufacturers Swix, Janus and Venås are also involved.

The plan is for ten MSc candidates to write theses based on the research.

Stretchable electronics

THIS IS COLDWEAR

An interdisciplinary project aimed at developing clothing for use under extreme conditions. Project duration 2008 – 2012.

Financed by the Research Council of Norway (NOK 13 million) and industry (NOK 4.5 million).

The project employs a total of 8–10 researchers. The oil companies Statoil and Total, and manufacturers Swix, Janus and Venås are also involved.

The plan is for ten MSc candidates to write theses based on the research.

The electronics that are integrated into textiles must also be flexible, like the material itself. This means that traditional conductive wiring cannot be used. Research scientist Arne Røyset and his colleagues are working on making certain areas of the textiles conductive with the aid of polymer plastics. Most polymers are poor conductors, but they are flexible and more comfortable against the body than metals.

The scientists are also looking at how to combine cobine two different polymer mater-ials so that together they become a temp-erature sensor. This is done by exploiting the thermoelectric characteristics of the materials. A difference in temperature between two locations can generate a tiny voltage, which can be measured.

“The challenge involves finding combinations of materials that have high thermoelectric capacity and good conductivity, and that are stable and robust,” explains Arne Røyset.

Microscale transport

Røyset’s team is also studying the ability of textiles to transport humidity and heat at a microscale. This is being studied on microscale, because it is at this scale that these properties lie, he explains, pointing out the unique capabilities of woollen fibres are an example of nature’s own high technology, he says: the material is both an excellent heat insulator and transporter of heat away from the body. These are properties of the nanostructure itself.

By Christina B. Winge