Clad pipes are used in the oil and gas industry for transportation of corrosive substances. A corrosion resistant alloy is applied to a backing steel, and the two components form a metallurgical bond. The bimetallic nature of the clad pipes can result in complex metallurgical changes when exposed to elevated temperatures, as the difference in chemical composition and thermal properties may result in a crack susceptible microstructure.

In my thesis, I am investigating the dissimilar interface between the clad and base metal. My previous work has shown that carbon migrates from the base metal to the clad during exposure to elevated temperatures, resulting in carbide precipitation and local hardening in the clad, and also cracking in the clad close to the girth weld. It should be noted that adding a Ni-interlayer between the clad and base metal provides a solution to the cracking problem related to the formation of a hard zone in the clad, but cracks may also arise from other mechanisms, such as hydrogen charging from cathodic protection (CP) or H2S during service. The cold cracking mechanisms in clad pipes is therefore highly relevant.

Transmission electron microscope (TEM) investigations have been performed in order to characterize the dissimilar interface and carbides. In TEM, electrons are transmitted through an ultra-thin specimen, which allows for detailed analysis of crystal structure and high resolution imaging. I have so far managed to characterize carbides, both on grain boundaries and inside grains (which felt oddly satisfying), and I also hope to characterize the microstructure at the interface.

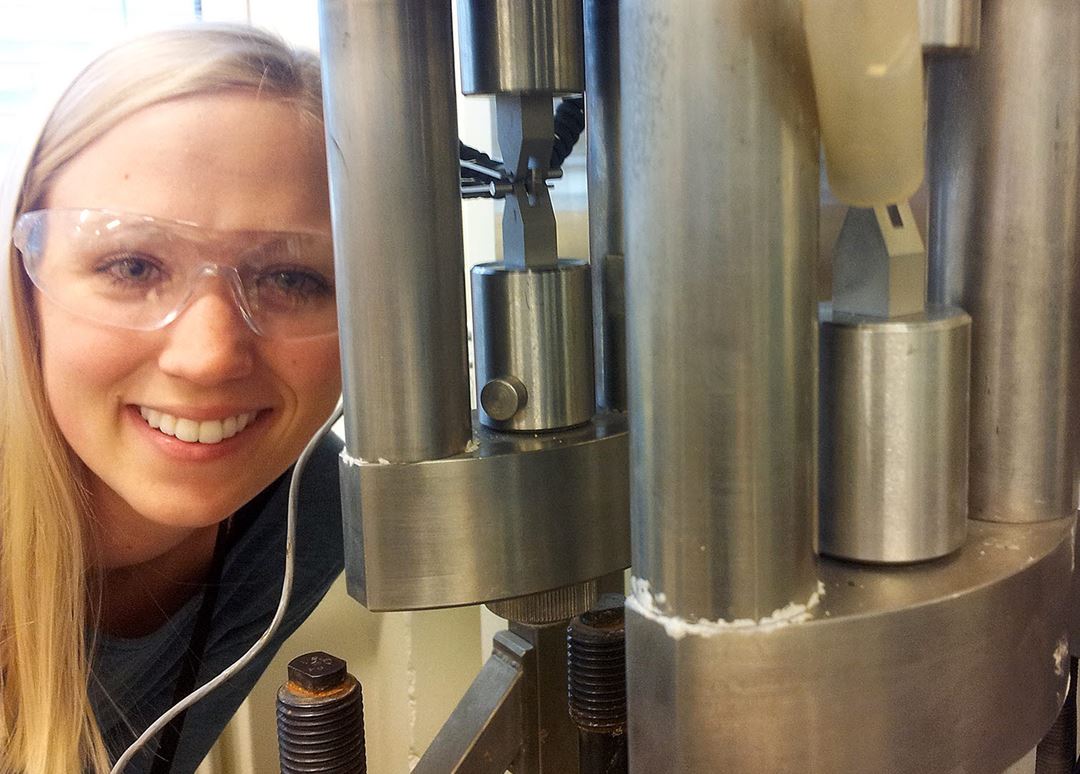

Additionally, I am performing fracture mechanical testing of the dissimilar interface, on samples with and without a Ni-interlayer. As the clad is quite thin (3mm), the samples are also quite small. In fact, no one has ever performed fracture mechanical testing of a dissimilar interface of this dimension, which is both challenging and exciting! Testing will be done in air and with the applied potential of CP. The goal is to evaluate the influence of the hardened region in the clad and assess the effect of hydrogen.

I have had a great time working with SINTEF and the ROP project, and it has been very exciting to be a part of an industrial research project. The chance to work with people who are experts in their field has been truly rewarding, and I hope to work with them again someday. Now I just have to finish my thesis before I head to Hawaii, where I will be presenting my work at the ISOPE conference.