The high-capacity wave maker and adaptable towing carriage allows for testing of large-scale objects and full-scale testing of components such as foils, streamers and cable or pipe sections.

The key features of the Towing Tank are:

- Main dimensions of 174 m (L) × 10 m (W) × 5.6 m (D).

- Multi-purpose carriage with speeds up to 6 m/s, serves classical ship model resistance and propulsion tests, Planar Motion Mechanism (PMM) tests at prescribed trajectories, as well as tracking of self-propelled models in seakeeping.

- Laboratory control system for automatic and unmanned testing to allow for efficient execution of large test matrices.

- Open water test rigs for conventional propellers, pods/thrusters, ducted propellers, ducted thrusters, contra-rotating propellers, etc.

- Carriage-mounted 6DOF Hexapod for conducting PMM tests and other forced-motion tests. Mounted on sway carriage for increased capacity in terms of stroke and speeds.

- Cable-driven parallel robot (CDPR) for application of external loads on ship models or floater models. Typically used for the application of sail and superstructure forces on wind assisted ships by use of cyber-physical testing, or for wind loads on ships without sails.

- Wave generation by use of paddle type wavemaker on one end of the basin, capable of producing regular, irregular, and extreme waves. The wavemaker was installed in 2024 and is equipped with active reflection compensation

- Wind generation by use of a movable fan battery, blowing at the test set-up from any heading angle. Both constant and varying wind (gust spectrum), can be provided.

Key Instrumentation:

- Precision dynamometers for resistance, propulsion and open water tests

- Large range of high-fidelity sensors and purpose-made dynamometers for measurement of propulsor forces, slamming loads, global wave loads, wave elevations, accelerations.

- Local optical position/motion measurement system on the carriage

- Automatic model tracking system

- Digital and analogue interfaces for real-time control system coupling to our physical models (e.g. ride control / motion damping systems, dynamic positioning systems, autopilot, USV control systems)

- Above- and under water HD camera system including use of Augmented Reality (AR) for information overlay.

Examples from the Towing Tank

Applications

Our Towing Tank equipped with state-of-the-art measurement systems provide essential support to develop and optimise ship performance:

Ship hydrodynamics

Within ship hydrodynamics our projects make use of the combined capacities of the Towing Tank, Ocean Basin, Cavitation Tunnel and numerical simulations to offer holistic investigation, optimisation and verification of performance across resistance and propulsion, seakeeping, manoeuvring, dynamic stability, slamming loads and green water on deck, as well as energy efficiency and operability at real seas.

Some of the ship hydrodynamic test capabilities in the Towing Tank:

- Ship resistance and propulsion tests

- Propeller in open water tests, steady and unsteady propeller blade loads, ventilation effects

- Seakeeping in head and following seas (for oblique seas we use the Ocean Basin)

- Local and global wave loads

- PMM tests to derive manoeuvring coefficients

- Energy Saving Device (ESD) performance

- 3D wake surveys

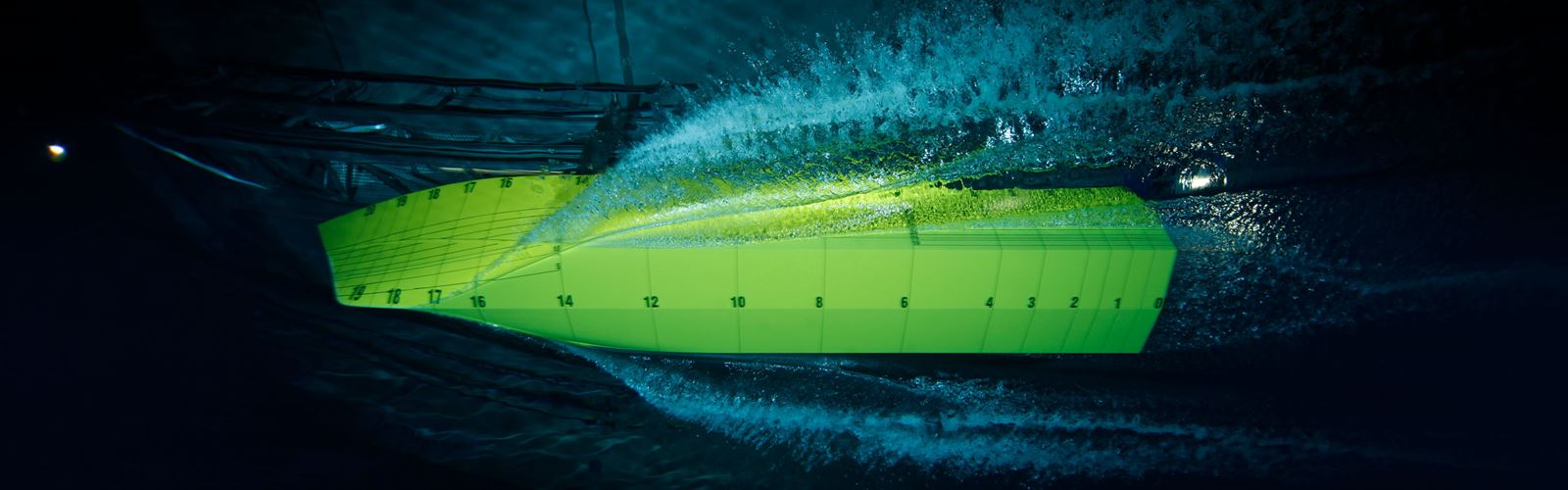

- Flow visualisation

- Hydrodynamic forces on submerged bodies

- Cyber-physical testing of wind-assisted and wind-powered ships

Within Offshore Hydrodynamics the towing tank is used when a long tank is needed such as for towing of structure in calm water or testing of long structures in waves.

Offshore hydrodynamics

Typical offshore projects that are performed in the towing tank:

- Towing of offshore structures to study VIM or fish tailing and to determine towing loads.

- Towing of risers, umbilicals and cables to study VIV

- Towing of fish farms to determine current induced loads and to study internal circulation in closed fish farms

- Testing of arrays of floating solar panels in waves, and where current is modelled by towing

- Forced motion of segments of floaters subjects to waves and current (modelled by towing)

Clients and projects

Our main clients and collaborators for model tests are ship designers, yards, technology providers, ship owners, authorities, navies and coast guards. The capacities of the towing tank serve model testing of everything from small high-speed boats, through ferries, SOVs, cruise vessels, RoPax and car carriers to the largest classes of container ships, bulkers and tankers. The projects range from pinpoint performance verification to in-depth physical studies for research programmes and software validation.

Model test campaigns in the Towing Tank are a regular part of the optimisation and verification projects of new designs, and to verify the gains from retrofit energy saving measures triggered by EEDI/EEXI or CII requirements.

Why choose SINTEF?

Our large-scale facilities and state-of-the-art equipment are designed to accommodate substantial models, high-quality environmental modelling and inclusion of interactions between physical models and onboard control systems for highly accurate results. This advanced infrastructure, combined with our unique problem-solving expertise, means we can tackle an extensive range of complex challenges for the ocean industries.

Beyond our cutting-edge facilities, you'll benefit from the collaborative environment at SINTEF. We are at the forefront of developing new knowledge and advanced simulation tools that directly support the ocean industries. Our close ties with the Norwegian University of Science and Technology (NTNU) further enrich our capabilities, providing access to a broad spectrum of research and academic excellence.

The Norwegian Ocean Technology Centre

We are currently building a new Ocean Basin and Seakeeping and Manoeuvring basin that will be part of the new Ocean Technology Centre. Today’s Ocean Basin and Towing Tank will be operational until the new Ocean Basin and seakeeping and manoeuvring basins are ready. More information about the Norwegian Ocean Technology Centre can be found here: The Norwegian Ocean Technology Centre.

Contact us

Interested in testing at our facility? Reach out to us for collaboration opportunities and facility bookings.