EnergyProSafe

Background

An accelerated utilization of Norwegian biomass resources that would reduce the CO2 footprint of the metallurgical industry is required.

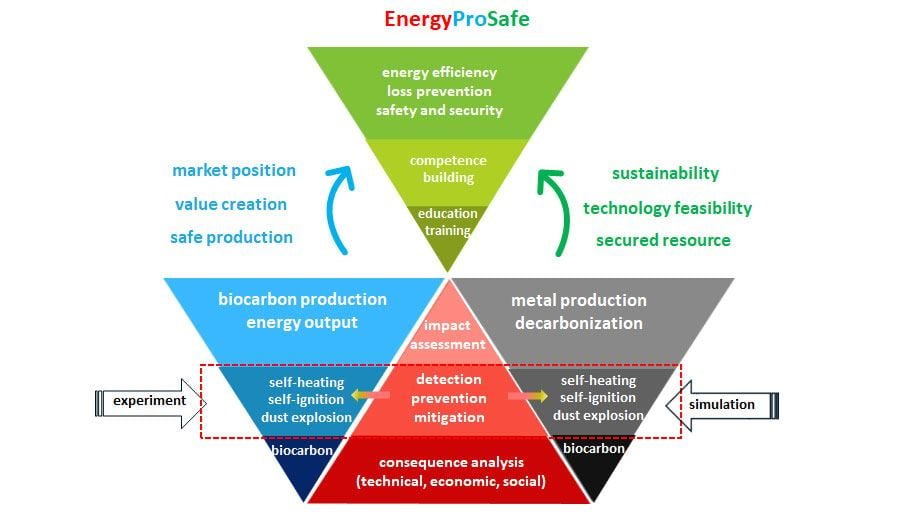

To boost contributions to the reduction of greenhouse gas (GHG) emissions and decarbonization of industries, the biocarbon (BC) value chains must be improved and tuned to remove technical and economic constraints, secure safe and efficient production, satisfy quality and quantity demands and ensure predictable and controlled long term BC supplement. The EnergyProSafe project responds to the national strategies on transition into a low-carbon-emission society and goals of the metallurgical industry by improving energy production and safety in BC value chains, securing safe and sustainable supply of BC of needed quality and in sufficient quantity. In addition, this project addresses safe and responsible production by identifying vulnerabilities and risks, developing detection and prevention measures and providing guidelines and recommendations to prevent accidents. Outputs from the project are valuable for industries carrying out proactive and systematic work in relation to health, safety and the environment (HSE) and making the working environment and safety level appropriate and satisfactory, see project concept below.

BC production processes need to be improved for maximizing mass yields and energy output, which are critical for techno-economics and profitability of BC production. During BC production, a significant fraction of by-products (i.e., gases and volatiles) are generated, which have a high temperature and contain combustible constituents. There is generally limited understanding about compositions and properties of these by-products, especially from continuous pilot and/or industrial scale BC production processes. It hinders identification and implementation of efficient measures to release the energy potential of the by-products, and overall energy output and efficiency of the BC production process. BC production generally covers several stages, including generation of BC at high temperature, cooling down of the produced BC, and discharging of the BC to containers. The BC discharged and loaded in containers will be further stored for days or even months in confined spaces. During both production and storage, there are risks related to self-heating and self-ignition of the BCs as they experience changing surrounding conditions (i.e., ambient temperature, humidity and availability of oxygen). The investigation of the safety-related risks during production and postproduction storage of BC is still at a very early stage. Systematic studies are needed to obtain fundamental understanding of root causes and triggering factors to promote safety. In addition, for producing a large quantity of BC, non-conventional biomass sources will be exploited to produce BC having properties that promote occurrences of self-heating and self-ignition. Further investigations are required to assess propensity and understand detailed mechanisms of the safety risks during postproduction storage of the BC derived from such non-conventional biomasses.

Metal production demands substantial amounts of energy and materials, particularly carbon as reductants. Large quantities of BC must be available for continuous metal production. Before reaching the furnace, the BC will experience short or long-distance transportation, unloading/reloading, and handling and storage at the metal production plants. Vulnerabilities and safety risks along this process must be identified and assessed. The mechanisms arising safety related risks during logistics are complex and are sensitive to material properties and surrounding conditions. The available knowledge is mainly derived from previous studies on solid fuels (i.e., coal and biomass). Nevertheless, the BC has significantly different physiochemical properties than these solid fuels. Detailed and systematic research and tests designed for BC should be conducted to obtain new understanding and insights into the root causes of safety related risks. Efficient strategies and measures are imperative to detect, prevent and mitigate the safety risks during transportation, storage and handling of BC for metal production, which are tailored to use BC for each specific metal production process. The effectiveness of these measures and impact on industrial operation and the surrounding environment should also be carefully evaluated. Furthermore, recommendations and guidelines for improving health and safety are needed.

Research, development and industrial practices aimed at production and utilization of BC have been addressed in the previous BioCarbUp and the ongoing BioCarbUpgrade project.

The EnergyProSafe project will fill the knowledge gap and build up knowledge and competence towards improving energy production and safety in BC value chains. Enhanced understanding and novel solutions to safety issues will improve adaptability and application of BC for metallurgical processes. For this to happen, research and development are needed across the span of the BC value chains through cooperation between R&D institutes and industries. The EnergyProSafe project consortium covers all key aspects, from production to end-use, and includes central industry players in the metallurgical and bioenergy areas in Norway.