Fuel cells that run on hydrogen are efficient and emit water vapour instead of exhaust. But so far, the technology is still expensive and therefore not competitive with the electric motor alternative.

Norwegian researchers have now figured out how they can can accelerate competitiveness by reducing two critical components. This could make fuel cells both cheaper and more environmentally friendly.

The technology has great potential to cut greenhouse gas emissions in the transportation sectors, especially in heavy transport, the maritime sector and – in a somewhat longer time frame – also in aviation.

Reduces need for expensive materials

Fuel cells consist of a membrane and a catalyst. Both are crucial for the process of converting hydrogen gas into electrical energy and for the overall performance of fuel cells. The membranes are made of fluorine-containing materials that are harmful to the environment, while the catalyst consists of platinum, which is a rare and expensive mineral.

By reducing the amount of platinum in the fuel cell, we’re not only helping to reduce costs, we’re also taking into account the global challenges regarding the supply of important raw materials and sustainability.

The membrane and the catalyst account for up to 41 percent of the total cost of fuel cells. That is why researchers at SINTEF chose to look at how these two components could be reduced.

The result? A cheaper and more environmentally friendly hydrogen fuel cell has now emerged in the laboratory. The solution is so light and thin that it makes an A4 sheet feel like thick cardboard.

Optimal material balance

The catalyst consists of innumerable platinum particles, each of which is like a microscopic reactor that converts hydrogen into electricity. The more reactors, the more electricity. However, the expensive materials also raise the costs.

“It was thus important to find the optimal balance between the amount of materials used and the amount of electricity produced. In the research project, we found a way to arrange the reactors so that they provided enough power to run the fuel cell, while at the same time drastically reducing the amount of materials required,” says Patrick Fortin, a researcher at SINTEF.

He explains that the research has led to a 62.5 percent reduction in platinum content, compared to state-of-the-art fuel cells.

“By reducing the amount of platinum in the fuel cell, we’re not only helping to reduce costs, we’re also taking into account the global challenges regarding the supply of important raw materials and sustainability,” says Fortin.

Platinum is one of the most expensive and rarest minerals on earth, and it is only extracted in parts of the world outside Europe. The EU has therefore categorized platinum as a critical raw material.

Solution reduces toxic emissions

The membranes used in this type of fuel cell contain fluorinated polymers that belong to a broader group, also known as per- and polyfluoroalkyl substances (PFAS). These are used in a number of products containing fluorine, including ski wax, Gore-Tex and fire-fighting foam.

The EU considers these materials to be an increasing chemical risk, because their production, degradation and disposal can lead to the release of harmful compounds that can cause serious health and environmental problems.

By slimming down the already razor-thin membrane by 33 percent, the researchers have now come up with a far more environmentally friendly membrane that is also less expensive.

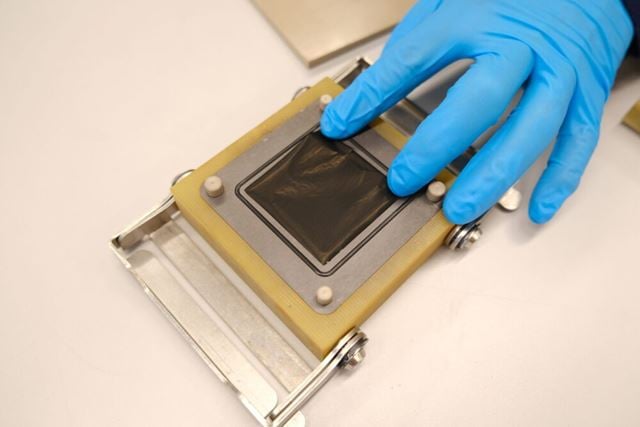

Patrick Fortin points to where the membrane and catalyst fit into the fuel cell at SINTEF’s Hydrogen Laboratory.

From razor-thin to even thinner…

“The membranes in today’s fuel cells are 15 μm (micrometres) thick. Our prototype measures just 10 μm. To put that into perspective, a standard A4 sheet has a thickness of 100 μm,” says Fortin.

During the study, SINTEF found that they had reached the limit of how thin a membrane could be before it affected performance. The results showed that the performance was nearly identical for both the 15 μm and 10 μm membranes. This balance, says Fortin, has to do with the membrane’s properties.

Facts about the project:

The research is part of the EU-funded CAMELOT project, which aims to better understand the factors that have limited the performance of current proton exchange membrane (PEM) fuel cells. The researchers at SINTEF collaborated with catalyst manufacturer Johnson Matthey and fuel cell manufacturer PowerCell. Johnson Matthey has produced catalyst-coated membranes with an area of 300 cm², and these have been tested in a PEM fuel cell designed by PowerCell for long-distance transport. The tests showed that the new membranes can be used commercially in fuel cell-powered vehicles at a lower cost and with a lower PFAS content.

Further collaborative studies with industry are planned to investigate the durability of the new membranes.

“The effectiveness of the new membranes rests on how quickly the protons can move across the membrane surface and into the catalyst layer, called ‘interfacial resistance,’ and how quickly they can move through the membrane itself, known as ‘bulk resistance’, says Fortin.

“During the tests, we noticed that the bulk resistance became negligible below 15 μm and that the performance was determined solely by the interfacial resistance, which was the same for both membranes,” he says.

Thinner – but more efficient. Now the researchers will test how long the new membrane lasts. Photo: Silje Grytli Tveten

The researchers concluded that going from razor-thin to even thinner did not compromise membrane performance, even though the amount of material had been reduced.

The researchers’ calculations showed that the total costs for the membrane in the hydrogen fuel cell could be reduced by up to 20 percent, while the content of the harmful PFAS could be reduced by 33 percent.

“If the innovations are put into practice, our research will contribute to making future clean energy technologies – like powerful PEM fuel cells – cheaper and more sustainable,” Fortin says.

Facts about PEM fuel cells:

PEM fuel cells are efficient, lightweight and compact. They are ideal for use in the transport sector. More than 55 000 PEM fuel cells were sold globally in 2022, and by the end of 2023, 5939 electric vehicles based on PEM fuel cells had been registered in Europe. These numbers are expected to increase as Europe's hydrogen roadmap aims to have 45 000 fuel cell buses and trucks on the road by 2030.

Source: SINTEF, Fuel Cell Industry Review 2022, Clean Hydrogen Monitor 2024, Fuel Cells and Hydrogen 2 Joint Undertaking, Hydrogen roadmap Europe.

We have already produced 300 cm² membranes and tested the new fuel cells at our partner facilities, with good results. Now all that remains is to investigate the durability of the new membranes, Fortin says.

- The research article was published in the Journal of the Electrochemical Society:

The Influence of Membrane Thickness and Catalyst Loading on Performance of Proton Exchange Membrane Fuel Cells. (DOI 10.1149/1945-7111/ad8267).