Egil Skybakmoen

Research Manager- Name

- Egil Skybakmoen

- Title

- Research Manager

- Phone

- +47 98 28 39 65

- Department

- Metal Production and Processing

- Office

- Trondheim

- Company

- SINTEF AS

As the name of this Research Area indicates, focus has been on developing and enhancing tools and methodologies to improve energy efficiency in industry. This is particularly the case for WP 1.1 KPIs, energy and exergy analyses, and WP 1.2, Process systems engineering, while WP 1.3, Future process framework, has been closer to end-users with a focus on future process frameworks within aluminium electrolysis.

Tools were developed for analysing and improving the use of energy in process industries. In this work, the use of thermodynamics has been central, and new methodologies have been developed using the concept of exergy (the quality of different energy forms). The tools developed include MultiEFF, a macro-based Excel workbook designed to evaluate various aspects of investments in energy-efficient technologies or measures. This tool assesses KPIs recommended by the WP, along with costs, impacts on the work environment, company reputation, potential risks, and health, safety, and environmental considerations. There have also been activities on integrating energy and exergy analyses in other models developed at HighEFF, such as the INTECUR model for optimising the energy systems of industrial clusters.

Generic tools and methods were developed in the field of Process Systems Engineering, such as Process Synthesis, Modelling & Simulation, Optimisation and Control. Some of the new methods have been tested successfully in collaboration with end users. Future energy systems were studied, addressing the transition from fossil fuels to renewable energy forms (solar and wind) and focusing on improving complex industrial utility systems, including steam level placement, flexibility and energy storage. The education aspect has been important in WP 1.1 and WP 1.2 with a total of 8 recruited candidates.

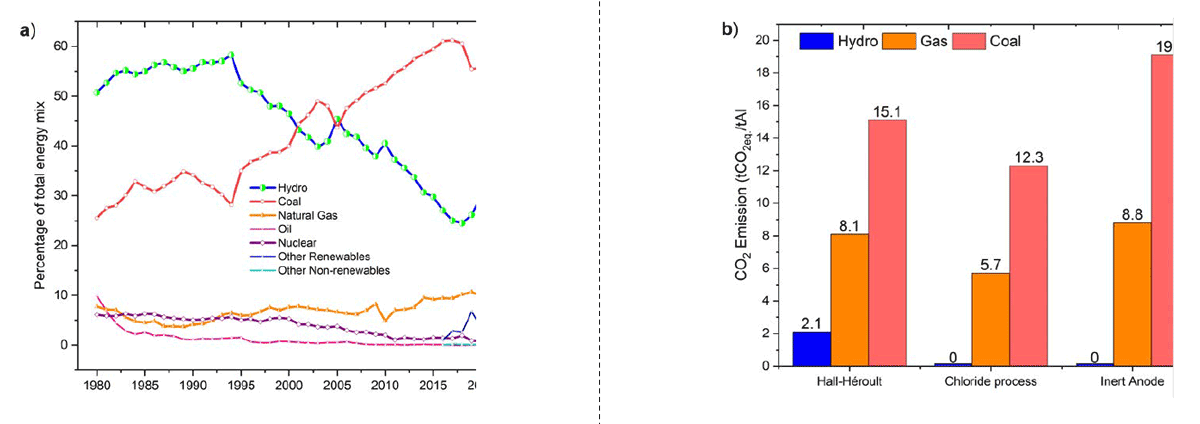

WP 1.3 has considered different future processes that can enhance energy efficiency and reduce the carbon footprint within the aluminium electrolysis process. Topics that have been considered include the chloride process, inert anode technology, improved Hall-Héroult process, biocarbon, pot gas recycling and energy recovery. The sustainability of the different production technologies was considered to highlight the differences with respect to energy consumption and carbon footprint.

A total of 8 candidates (5 PhDs and 3 postdocs) and 4 associated PhDs have been active in RA1. These 12 researchers have produced 87 journal publications. Candidates have received 5 awards for their research. RA1 collaborated with MIT and the University of Manchester. Focus has been on enhancing existing and developing new methodologies in the field of Process Systems Engineering with a special emphasis on Energy Efficiency in industry. The recruited candidates have ended up in industry (3), academia (4), research institutes (3) and consulting companies (2).

Half of the candidates now work in Norway; the others are spread in 4 countries. All models developed will certainly be valuable in coming years.

All work performed in WP 1.3 Future Process Framework has been published and presented at various international conferences. A total of 12 popular and technical/scientific articles were published, in addition to workshops with industrial partners. Moreover, the topics considered have brought about spin-off projects as listed below:

Like all industries, the aluminium industry is facing challenges related to energy consumption and environmental issues. Therefore, all subjects studied under WP 1.3 are currently considered as hot topics within the aluminium community worldwide. Contacts have been established between SINTEF and European Aluminium (HOME - European Aluminium) regarding electrification and decarbonisation of the Al industry.

The activities in RA1 are of a fundamental character with considerable focus on PhD education and postdoc research. We originally had six PhDs and two postdocs. One of the PhDs withdrew halfway, and the remaining funds were used to recruit a third postdoc.

One PhD defended her thesis in 2023 (Cristina Zotica, NTNU), and one in January 2024 (Suzane Cavalcanti, MIT), so the academic work force in RA1 is now reduced to only one remaining postdoc. Since its start, HighEFF has also recognised so-called Associated PhDs that have contributed considerably to the Centre’s research and publications without being funded by HighEFF. Four such Associated PhDs have contributed to the activities in RA 1; two of these in the early days of the Centre (2017-2019) and two in the late phase. Ting He (double degree NTNU and Shanghai JTU) defended in May 2023 and Siyue Ren (Xi'an JTU) returned to China October 2023 and is expected to defend her thesis in June 2024.

The PhD student who finished in 2023 (Cristina Zotica) studied the Optimal Operation and Control of Thermal Energy Systems. During her PhD programme, she received a Best Paper Award (among 250 papers) from ESCAPE-29 in Eindhoven, The Netherlands, in 2019. Associated PhD Ting He studied liquefaction of natural gas with high ethane content (that was extracted) while capturing CO₂ using a low temperature process. Associated PhD Siyue Ren used a Stirling Engine and heat from the sun to improve the Round-Trip Efficiency (RTE) of Liquid Air Energy Storage for power from renewables.

The PhD students and postdoc that have contributed to RA1 in 2022/2023 have produced 13 journal publications in 2023 and attended two conferences with presentations and short papers. They are Julia J. Romero, Zhongxuan Liu, Cristina Zotica, Juejing Sheng (who discontinued), Nidret Ibric, Ting He and Siyue. Ren.

We continued work on the Excel tool that compares potential benefits of new energy-saving or CO₂-mitigating solutions. In collaboration with Hydro, we focused on documenting and rigorously testing this tool. Currently, we are revising it to address specific usability challenges. The goal is to create a flexible and well-documented tool that will be readily available to the industry by the spring of 2024.

Additionally, we made strides in refining the INTERCUR model — originally developed as part of an earlier NEIC activity. The aim was to enhance its dynamism and align it more closely with the KPI recommendations for HighEFF. In the autumn of 2023, we conducted a workshop at Mo Industrial Park to explore how this model could better cater to the industry’s specific needs.

A mapping study was conducted for the energy use, greenhouse gas emissions, and sustainability of the different aluminium production technologies that have been investigated by WP 1.3 since HighEFF’s launch. The work performed in 2023 revisited the different technologies previously studied, looking at their energy consumption, climate footprints and sustainability. The study further highlighted the importance and impact of the energy source on the environmental friendliness and sustainability of aluminium production. Figure 1 displays the energy source trends and CO₂ footprints of the different technologies based on three of the major energy sources considered. A conference paper, Sustainability of Different Aluminium Production Technologies, was presented at the TMS 2024 conference in March 2024 in Orlando, Florida.

In addition to the aforementioned conference papers, two more papers will be presented and are partly financed by HighEFF:

Both papers are of fundamental character but examine important topics for understanding and improvements of efficiency for the Al electrolysis process. We assume all three papers will gain a lot of international interest at the conference.

The activities in RA1 are of a fundamental character with considerable focus on PhD education and postdoc research. We originally had six PhDs and two postdocs. One of the PhDs withdrew halfway, and remaining funds were used to recruit a third postdoc. Two PhDs defended their thesis in 2022 (Julia Jimenez Romero and Zhongxuan Liu), and one in February of 2023 (Cristina Zotica), so the academic work force in RA1 is now reduced to one PhD and one postdoc. An important element of the education programme in RA1 has been international collaboration with MIT in the US and the University of Manchester in the UK. The professor-pair model was implemented with these 2 universities.

The two PhD students that finished in 2022 (Romero and Liu) both studied future energy systems related to the transition from fossil fuels to renewable energy forms (solar and wind). Romero focused on improving complex industrial utility systems, including steam level placement, flexibility and energy storage. Liu has demonstrated that the Round-Trip Efficiency (RTE) for Liquid Air Energy Storage (as a promising way to store electricity from renewables) can be improved from 54 to 68% by optimising the flowsheet structure and selection of working fluids to exchange and store hot and cold thermal energy.

Three PhD students in RA1 (Cristina Zotica, Julia Jimenez Romero and Zhongxuan Liu) have produced seven journal publications in 2022 and attended four conferences with presentations and short papers. Interestingly, these three PhDs have all considered energy storage; Julia and Zhongxuan for design and Cristina for control.

The year 2022 saw a sidestep or an elaboration on the KPI work that has already been carried out as part of RA1. After meetings with HighEFF partner Hydro, we saw the need to expand the current perspective to enumerate other potential benefits of new energy-saving or CO₂-mitigating solutions, especially for projects that at first glance do not look so promising, due to other seemingly more attractive projects in the portfolio. To accommodate this request, considerable work was put into making an excel based tool that allows the user to attribute various benefits to new projects and rank them based on different aspects such as contributions to HSE guidelines, company or societal reputation, work environment, and risk mitigation. In addition, the tool includes a total operating and investment cost breakdown, as well as the KPIs that have already been developed within RA1. Hydro played an active role in the development of the tool and provided useful input along the way. Relevant case studies were also devised to test the tool's capabilities and to demonstrate its potential in the decision phase. The plan is to continue working on this tool in 2023 and have a complete version ready by the end of the year.

Also, flue gas recycling and energy recovery has shown from the work done in 2021 and 2022 to provide an excellent opportunity for the aluminium industry to reduce its total energy consumption and to prepare for a possible future carbon capture and storage or utilisation technology. Gas recycling enables increased CO₂ concentration and more efficient recovery of energy from the flue gas. The work performed in 2022 presented some of the challenges with this technology, including increased concentrations of other pot gases such as CO, SO₂ and HF and possible increased fugitive emissions due to reduced suction. Increased concentration of CO is particularly unwanted, since it is a lethal compound. Thus, catalytic conversion of CO to CO₂ is crucial for HES (Health, Environment and Safety) reasons, and it also increases the amount of collectible heat. However, high concentration of SO₂ can pose problems to equipment, including the heat

exchanger units, due to the formation of sulfuric acid when the acid dew point is reached. Two papers with topics relating to the challenges of pot gas recycling were presented at the TMS 2022 conference in Anaheim in the USA from 27 February to 3 March 2022.

Furthermore, a pilot scale plant was installed at the Alcoa Mosjøen plant in Northern Norway through the AGATE project (led by REEL Norway). The plan was to perform some measurements there, however due to unforeseen challenges the measurements had to be postponed to 2023. Despite the challenges, a work on the theoretical evaluation of the dynamic gas concentration behaviour in the aluminium electrolysis cell was done. This work would be complemented by the industrial gas measurements to be done in 2023.

The potential for increased heat recovery is huge in the aluminium industry (up to 1.8 TWh estimated in RA1 and RA6), and if part of this energy can be used in the CCS process, it would enhance future developments for CCS from Al electrolysis process in the future. But several technological issues relating to heat exchanger design, etc. need to be solved before implementation. RA4 investigated the design of heat exchangers for utilisation of waste heat at the Hydro Sunndalsøra and Alcoa Mosjøen plants.

The activities in RA1 are of fundamental character with a total of 5 PhD students (1 PhD defended in 2020). Due to some delays, we did not have defences in 2021 but we assume there will be 3 defences in 2022. The PhD activities include a close cooperation between MIT and NTNU with one PhD student working on the same topic. There is also an international cooperation between UoM and NTNU with 2 PhD students Professor Robin Smith from UoM actively co- supervises the PhD at NTNU. Here, the topic is to explore energy storage technologies for the shift from fossil to renewable energy sources for future distributed energy hubs.

Another task in RA1 is to discuss the taxonomy of KPIs within the scope of HighEFF and suggest a basis for common assumptions that can be used for assessing the goals of the HighEFF program.

The evaluation of case studies has been discussed in a delivered report, and the importance of establishing the basis for the comparison is emphasised A section is also devoted to the Best Available Techniques Reference Documents (BREF) available from the European IPCC Bureau To enable a consistent evaluation of HighEFF results, it is important to establish a common ground for comparisons. The use of a taxonomy for key performance indicators enables a clearer and unambiguous communication of what the indicator represents. Being clear about the scope and boundaries of the analysis also aids comparisons both against multiple base case references and across case studies. Additionally, it is important to establish common ground by using the same reference parameters and conversion factors, or as a minimum clearly state the basis used Having a well-defined basis makes sure that the results can be re-assessed if required when the energy market and production technology change. HighEFF has an emphasis on Norwegian industries. With the proximity and close integration with the EU it is a natural choice to adopt the methodology described in the Best available techniques Reference documents (BREF) from The European IPCC Bureau In some sectors such as the ferro-alloy industries, Norway is a leading country and reference for the BREF Making systematic use of the available BREFs when establishing reference cases and assessing the innovations is therefore highly recommended

Also, this year, we have – together with the Aluminium industry: Hydro, Alcoa and REEL Norway – evaluated some ideas concerning the flue gas from aluminium electrolysis plants, focusing on the possibilities for increased heat recovery and increased concentration of carbon dioxide. The emission of CO₂ from the aluminium industry in Norway is at around 2 Mton/year However, the concentration of CO₂ is only 1 vol % and too low for economic future CO₂ capture technology Furthermore, close to 41 % of the waste heat corresponding to ca 3 MWh/ton Al is lost via the flue gas.

Flue gas recycling and energy recovery provide an excellent opportunity for the aluminium industry to reduce the total energy consumption and to prepare for a possible future carbon capture and storage or utilisation technology Gas recycling enables increased CO₂ concentration and more efficient recovery of energy from the flue gas. The work performed in 2021 presented some of the challenges with this technology, including increased concentrations of other pot gases such as CO, SO₂ and HF and possible increased fugitive emissions due to reduced suction Increased concentration of CO is particularly unwanted, since it is a lethal compound. Thus, catalytic conversion of CO to CO₂ is crucial for HES (Health, Environment and Safety) reasons, and it also increases the amount of collectible heat. However, high concentration of SO₂ can pose problems to equipment, including the heat exchanger units, due to the formation of sulfuric acid when the acid dew point is reached Two papers with this topic will be presented at the TMS 2022 conference and a Teams WS with around 30 participants was arranged in December.

The potential for increased heat recovery is huge in the aluminium industry (up to 1 8 TWh estimated in RA1 and RA6), and if part of this energy could be used in the CCS process, it would enhance future developments for CCS from Al electrolysis process in the future. But several technological issues need to be solved before implementation We will address those topics in more detail in 2022 together with our industrial partners.

Senanu, Solheim and Skybakmoen also published a popular science article in Gemini and TU "Sju veier til grønnere aluminium" in July 2021, with many comments as well.

The activities in RA1 are of fundamental character with a total of 6 PhD students (5 from March). The first HighEFF PhD student, Matias Vikse, defended his work in February: "A Nonsmooth Approach to Modeling and Optimization – Applications to Liquefied Natural Gas Processes and Work and Heat Exchange Networks". During his PhD period, he and his co-authors have delivered 15 journal publications and 7 conference proceedings. This also includes a close co-operation between MIT and NTNU with one PhD student working on the same topic. There is also an international co-operation between UoM and NTNU with 2 PhD students. Professor Robin Smith from UoM actively co-supervises the PhD at NTNU. Here the topic is to explore energy storage technologies for the shift from fossil to renewable energy sources for future distributed energy hubs.

There have been some partner involvements worth mentioning this year. First, the work to investigate the potential for increased energy use and reduced CO2 emissions at Mo Industrial Park. The work is important to optimise the cluster itself with respect to energy utilisation and environmental aspects but also to include new activities (for instance bio- carbon production, post-consumption carbon capture or others). Results indicate that the energy recovery can be increased from 400 GWh to 640 GWh at Mo Industrial Park. This work will continue in RA1 in 2021, partly in RA6, and also in the NEC INTERCUR project started autumn 2020.

The second partner involvements to be mentioned is process control systems of waste heat generated from Elkem Thamshavn. The work is based partly on the PhD student work by C. Kotiza, associate PhD Student D. Rohde, and resources from SINTEF Energy and the industrial partner Elkem. The work titled “Energy recovery from furnace off -gas: Analysis of an integrated energy recovery system by means of dynamic simulation” has been published. By introducing dynamic simulations tools, the integrated system for energy recovery from furnace off gas has been analysed. Preliminary results indicate an increase in electricity generation of around 5%.

The third topic is related to the Aluminium industry (Hydro, Alcoa and GE Power) where the key point is a critical evaluation of innovative ideas concerning the flue gas in aluminium electrolysis plants, focusing on the possibilities for increased heat recovery and increased concentration of carbon dioxide. The emission of CO2 in Norway is around 2 Mton/year from the aluminium industry. However, the concentration of CO2 is only 1 vol % and too low for eventual future CO2 capture technology. Therefore, a concept involving recycling the gas and introducing heat exchangers and catalysts is under evaluation – illustrated in the figure. A workshop was arranged in May with around 30 participants. A paper was published at TMS in 2020, and close co-operation with the partners is established.

The potential for increased heat recovery is huge in the aluminium industry (up to 1.8 TWh estimated in RA1 and RA6), and if part of this energy could be used in the CCS process it will enhance future developments for CCS from Al electrolysis process in the future. But several technological issues need to be solved before implementation. We will address those topics in more detail in 2021 together with our industrial partners.

One important task for RA1 is to use relevant KPIs for energy and resource efficiency. Alternative Key Performance Indicators (KPIs) have been tested and evaluated for an industrial case at Mo Industripark (MIP). Process data has been collected to describe the energy flows between industrial clients located at MIP.

The annual energy flow (in GWh) was visualised in the form of Sankey diagrams while the quality of the available energy is presented in the form of a grand composite curve which describes the amounts of latent energy available at different temperature levels. High temperature flue gas from ferrosilicon (FeSi) production at Elkem Rana represent the largest heat source available for utilisation. A theoretical assessment of potential applications for this energy is presented and includes:

The theoretical studies indicate that the MIP ambition from 2016 of increasing the energy recovery from 400 GWh to 640 GWh is realistic and may contribute both to increasing the energy recovery and facilitate overall reductions in the carbon footprint of the activities at MIP.

PhD Vikse and PD Yu further developed Work and Heat Integration (WHI). Two review papers were published in 2019. WHI is now established as a new research field in HighEFF with considerable potential for industrial applications.

The main difference from established heat integration methods is that heat from compression and cooling from expansion are added to the basic heat recovery problem. Early results indicate considerable improvement to industrial energy systems. By making modest sacrifices in mechanical energy (work), significant savings can be obtained in thermal energy (heating and cooling). This has close connection to heat pumping, however, regular process streams are used as working fluids.

Considerable work was done on using Organic Rankine Cycles (ORCs) for power production from low temperature Waste Heat. The disadvantage with ORCs is their low efficiency in traditional applications, however, when combined with low temperature heat sinks (such as LNG regasification), the efficiency and economy can be quite good. The collaboration with Prof. Barton at MIT on developing a new paradigm for simulation and optimization has progressed. The methodology is referred to as Non-smooth Analysis and has been applied to LNG processes (multi-stream heat exchangers) and distillation columns.

Aluminium electrolysis by the Hall-Héroult process is energy intensive. In Norway, 18 TWh of electric power is consumed (12-13 % of the Norwegian production) for manufacturing about 1.2 Mton aluminium. The process emits around 2.1 Mt CO2-equivalents.

Earlier we evaluated alternative processes to today's Hall-Heroult (inert anode technology and chlorination route). We also intended to evaluate new concepts and solutions for use in today's HH- process, creating a basis for continued research on methods and means for decreased energy consumption and environmental footprint.

In 2019 we had a detailed study of recycling of flue gas in Al electrolysis cells. We want to recycle flue gas because this will give higher concentration of CO2 (today it is around 1 vol %), thereby enabling carbon capture technologies in the future. Another advantage is to increase the energy recovery potentials by introducing heat exchangers in the gas-system However, it is several challenges to be solved and therefore this will be followed up by a workshop in 2020 with industry partners and SINTEF.

All 6 PhD students are now recruited. One Post Doc (PD) (of two) finished the work from 1.7.2018. International collaboration is established with University of Manchester (UoM) and Massachusetts Institute of Technology (MIT) and one PhD student (Vikse) stays at MIT until summer 2019. 18 journal papers and 16 proceedings/papers for conferences was published and presented in 2018.

One important task for RA1 is to use relevant KPIs for energy and resource efficiency. PD Magnanelli fulfilled her work within KPI's and Exergy indicators for industrial practice during 2018. A workshop titled "RA1 + RA4 Workshop on KPIs, process improvements and surplus heat recovery" was arranged in Trondheim June 2018. From industry Elkem, Eramet and Mo Industripark were present together with SINTEF and NTNU researchers. Based on work performed earlier and discussions during this workshop a report "Definition of case studies" was delivered, giving the directions to further work in 2018 and 2019. A case study will be performed at Mo Industripark (MIP).

PhD Vikse and PD Yu are studying Work and Heat Exchange Networks (WHENs), Waste Heat Recovery by using ORCs and various Polygeneration concepts. Together with Prof. Truls Gundersen they received the Best Paper Award at the Escape conference in Graz, titled "Comparison of reformulations of the Duran-Grossmann model on Work and Heat Exchange Network Synthesis (WHENS)". Work and heat integration is established as a new field. Participating with MIT/Prof. Barton in development of a new paradigm for simulation and optimization is established. The work is non-smooth analysis for (hybrid)modelling and appliedto LNG processes.

Aluminium electrolysis by the Hall-Héroult process is energy intensive. In Norway, 18 TWh of electric power is consumed (12-13 % of the Norwegian production) for manufacturing about 1.2 Mton aluminium. The process emits around 2.1 Mt CO2-equivalents. The focus in HighEFF is to evaluate some alternatives to the traditional Hall-Heroult process.

The paper "Inert Anodes – the Blind Alley to Environmental Friendliness?" was presented in a large international conference (TMS) in March 2018 with good feedback and interest. A truly inert anode has not yet been developed, but the foundation of Elysis in Canada (Rio Tinto, Alcoa and Apple) shows willingness to develop a new process. The evaluation of the chloride process with less energy consumption and CO2-footprint was finalized early 2018 with the report "Carbochlorination routes in Al production". This route is to be followed up by an industrial partner. New concepts and solutions for use in today's HH- process has also been evaluated, creating a basis for continued research on methods and means for decreased energy consumption and environmental footprint.

Advanced exergy analysis of the oil and gas processing on a North Sea platform is the key activities for a PhD study starting late 2018. This activity will be further planned with industrial partners and ongoing in 2019 with high focus.

Recruitments of PhD students (5) and PDs (2) is in place at NTNU. Together with SINTEF and MIT resources this has result in a very good and impressive publication production with 7 journal papers and 10 proceedings/papers for conferences. International collaboration is established with UoM and MIT and will be even more strengthen the coming years. Participating with MIT/Prof. Barton in development of a new paradigm for simulation and optimization is established. The work is non-smooth analysis for (hybrid) modelling and applied to LNG processes. Work and heat integration is established as a new field. A special session was organized at PRES'2017 in Tianjin and was crowned "highest attended and best session of the conference."

One important task for RA1 is to use relevant KPI's for energy and resource efficiency. Internal meetings, as well as the 3 workshops arranged by RA6 case studies, have been very useful to define and evaluate different methods. Discussions and work regarding KPI's and usage of exergy metrics is published in a journal (draft version for reviewing) as well as reported in a report. This work will be continued in closer co-operation with HighEFF members in 2018 and coming years. A workshop is planned to be arranged with industrial partners in 2018.

Production of aluminium is a very energy intensive process and emits also huge amounts of CO2. Inert anodes (non-fossil carbon) have been evaluated as an alternative process. However, inert anodes will use 3 MWh/t Al more DC energy consumption than carbon anodes. Hence, the energy source for Al production will be essential for lowering the CO2-footprint. Only usage of renewable energy sources will give less CO2 emissions with inert anodes. Usage of carbon anodes with CCS technology consumes less power than inert anodes. A truly inert anode has not yet been developed. The paper "Inert Anodes – the Blind Alley to Environmental Friendliness?" will be presented in in a large international conference (TMS) in March 2018 with all the worlds Al producers present.