|

The MEMS-pie project:

|

Sixth Framework Programme |

You are here:

MEMS-pie

/

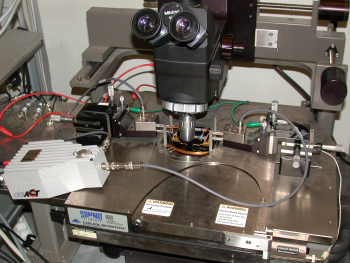

Testing and characterisation